A kind of internal groove measuring instrument

A measurer and inner groove technology, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as difficult detection accuracy, difficulty in the position and size of inner grooves, difficulty in meeting the needs of measuring auto parts, etc., to achieve measurement Increased speed and accurate measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

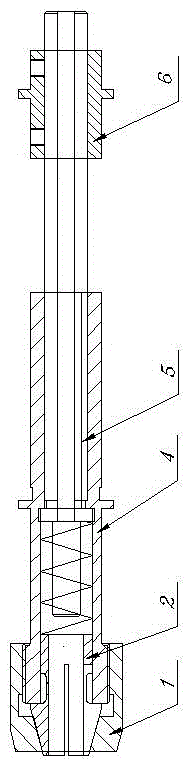

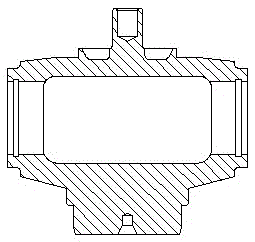

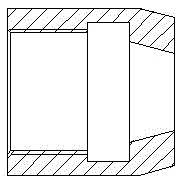

[0020] For an in-depth understanding of internal groove measuring instruments, combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 described as follows:

[0021] The inner groove measuring instrument is divided into three parts, the instrument part, the fixed part and the dynamic part. In the inner diameter of the card flap of the chuck head 2, the lock nut 1 is fixed together with the first measuring set 4, the compression spring 3, the elastic contact rod 8 of the instrument, the measuring rod 5, and the second measuring set 6 are linked together, belonging to The dynamic part can measure the size of the groove;

[0022] Measuring technology principle: see figure 1 The product groove structure, the working principle of the inner groove measuring instrument is based on the width and depth of the workpiece product groove, firstly process the positioning cam of the first measuring set 4, and then process the second measuring set 6 mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com