A gas micro flow measuring device

A measuring device and micro-flow technology, which is applied in measuring devices, liquid/fluid solid measurement, flow/mass flow measurement, etc., can solve problems such as difficulty in measuring small pressure changes, difficulties in measuring small volume changes, and immature understanding of flow mechanisms , to achieve the effect of convenient data picking, improved resolution and accuracy, and stable pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

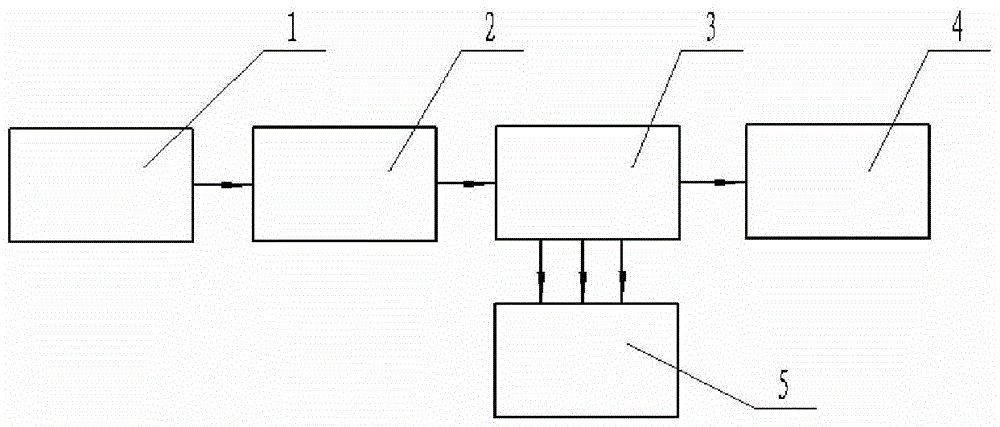

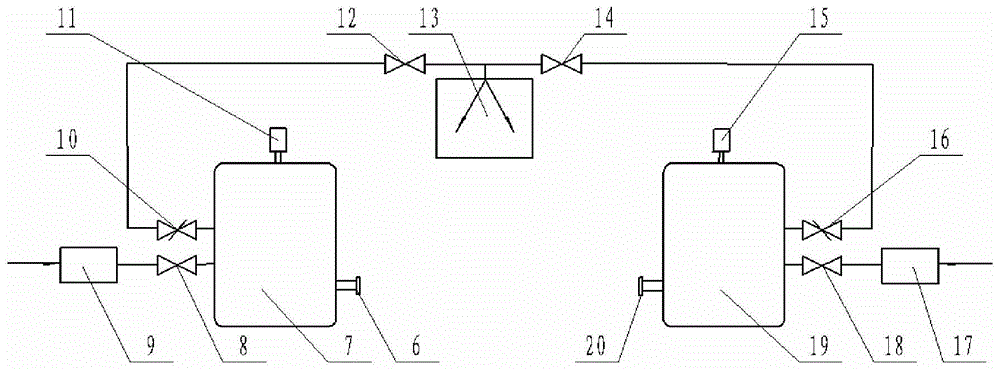

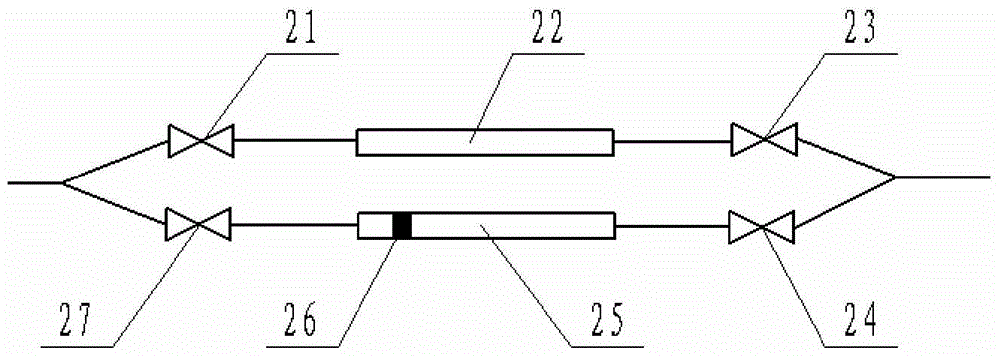

[0014] Such as figure 1 A gas micro-flow measurement device is shown, including an inlet stabilizing container 1, a micro-nano channel or device 2 to be tested, a dual-channel volume indicating unit 3, an outlet stabilizing system 4, a vacuum pumping system 13 and an image recording unit 5 , wherein the inlet voltage stabilizing system 1 is tested micro-nano channel or device 2, the dual-channel volume indicating unit 3, and the outlet voltage stabilizing container 4 are sequentially connected in series to form a closed gas flow space; figure 2 As shown, the inlet pressure stabilizing system 1 includes connecting the first valve 8 and the inlet container 7 sequentially through a conduit, and one port of the inlet container 7 is connected to the first throttle valve 10, the The three valves 12 are fixedly connected to the first pressure sensor 11 and the inlet container interface 6 respectively to the inlet container 7; the outlet pressure stabilizing system 4 includes using a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com