Sawtooth-shaped structure surface sample making mould with adjustable angle and size

A technology of jagged and structural surfaces, applied in the field of structural surface sample preparation molds, can solve the problems of inability to reflect particularity, high sample preparation costs, unreliable results, etc., and achieve material saving, quick use of costs, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

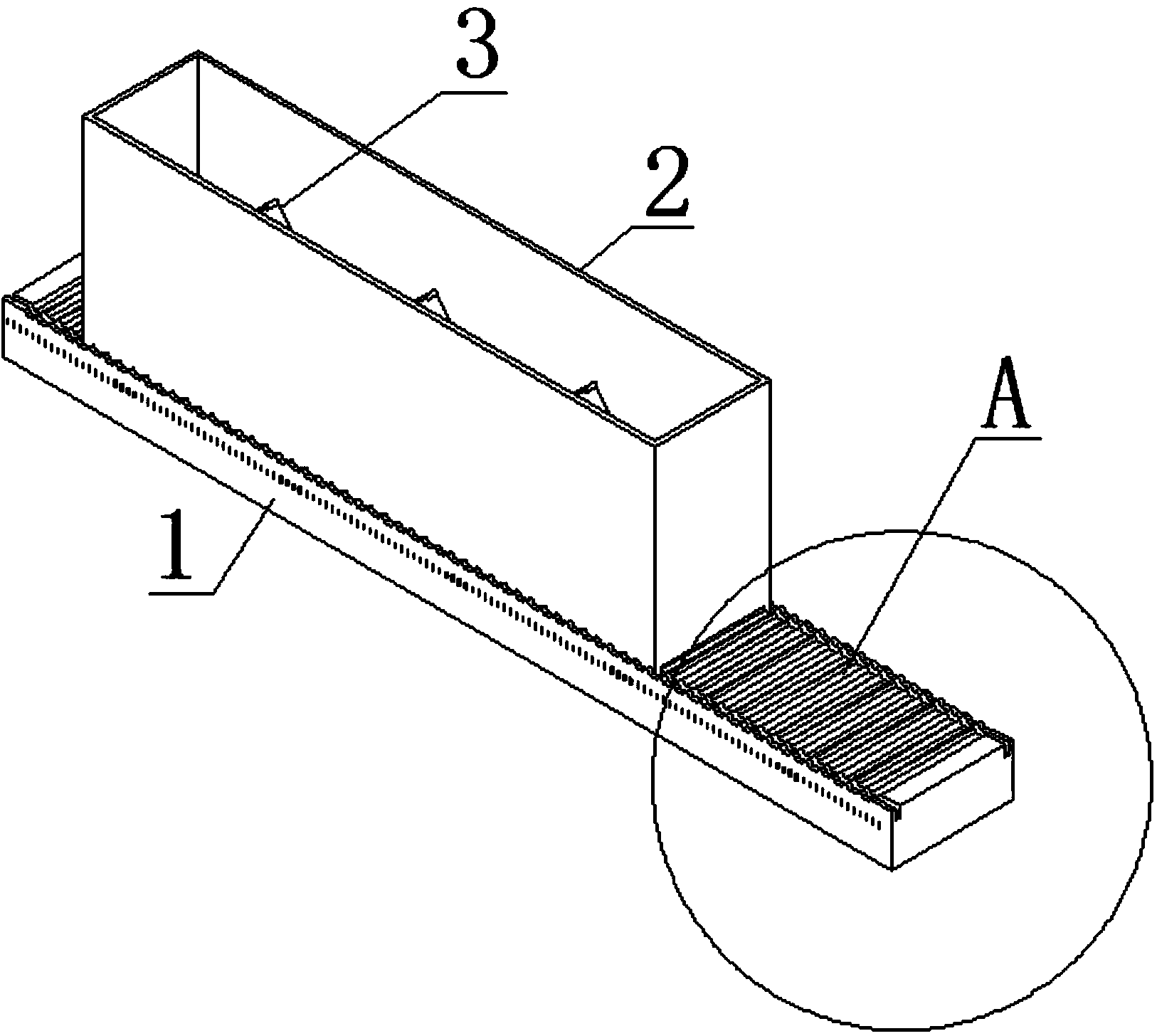

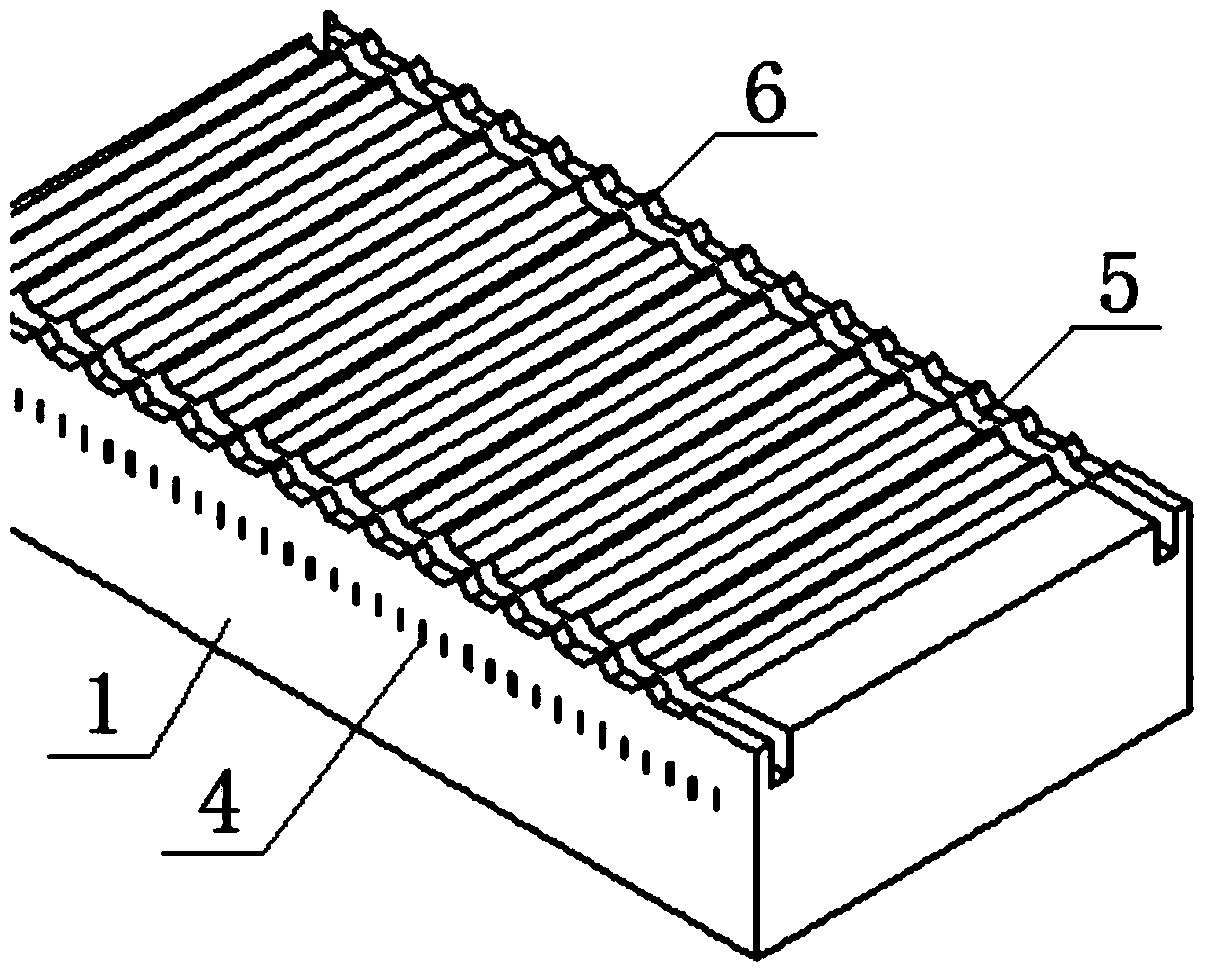

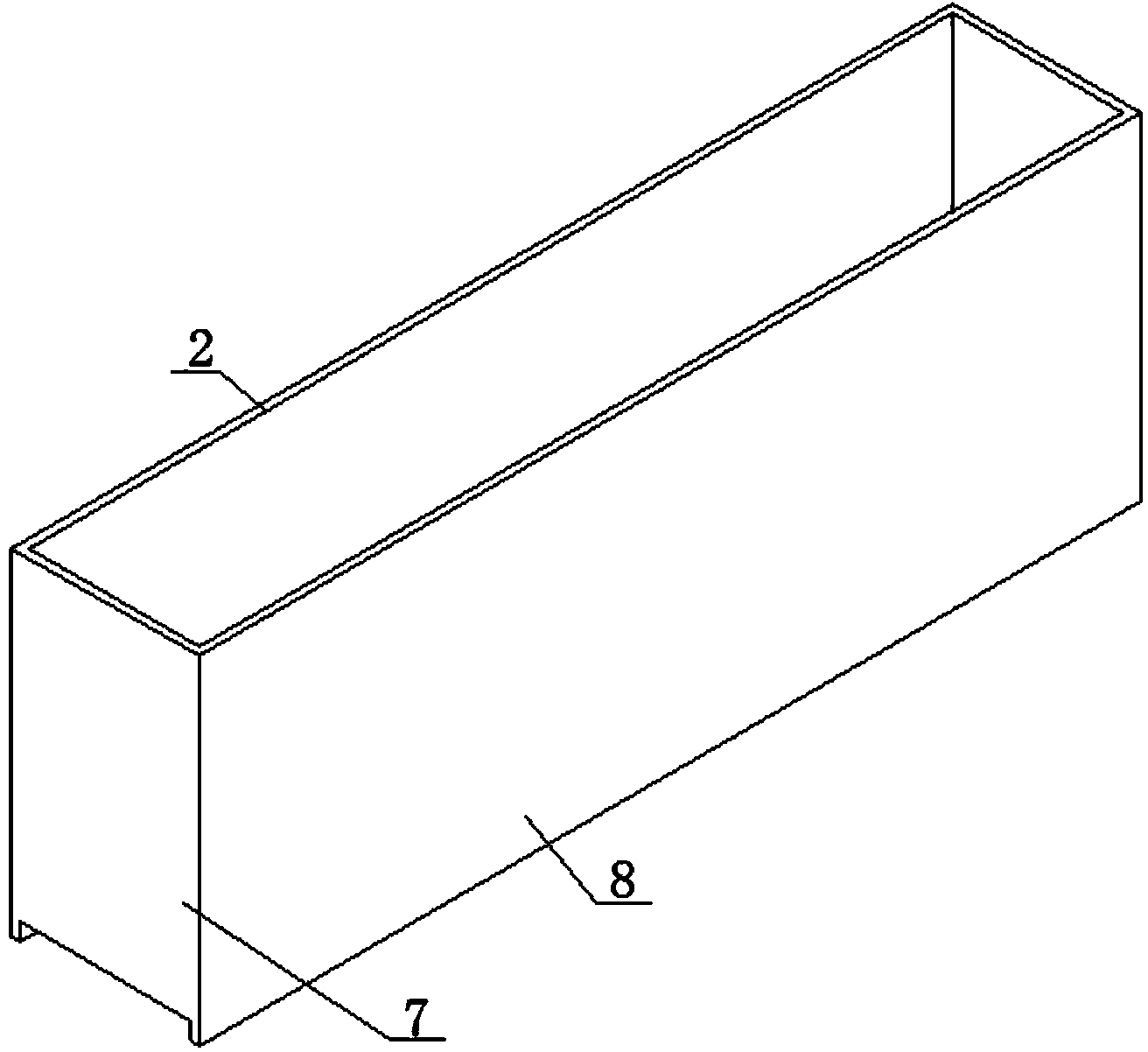

[0033] Embodiment 1: A structural surface sample preparation mold with adjustable angle and size provided by the present invention, its overall structure is as follows figure 1 As shown, the mold adopts a modular design, including a positioning base 1, a mold outer frame 2 and a toothed movable plate 3. The positioning base 1 is a stainless steel rectangular frame, see figure 1 , 2 6. The side of the positioning base is provided with a positioning scale 4, and the upper surface of the positioning base is provided with a whole row of toothed grooves 6, and both sides of the outer ring of the whole row of toothed grooves are provided with concave stops 5; Board 3 is composed of a plurality of flexible slot boards and plug-in boards connected together, see Figure 4 , 5, 6, the slot plate 9 in the described assembly is a hollow rectangular slot with an open end, one side of the slot plate is provided with two screw holes, the other end of the slot plate is provided with a slot ...

Embodiment 2

[0037] Embodiment 2: Using the method of sample preparation mold for structural surface sample with adjustable angle and size provided in Embodiment 1, the specific operation steps are as follows:

[0038] Step 1. Before using the mold of the present invention to make the test model, first determine the undulating angle and size of the structural surface to be tested, fix the positioning base 1 on the horizontal table or the ground, and connect the single slot plate and insert plate assembly , and then the single assembly and the assembly are sequentially connected by pivot pins to form a long toothed movable plate 3 of multiple assemblies.

[0039] Step 2. According to the adjusted structural surface undulation angle and size of the positioning scale 4 on the outside of the positioning base 1, adjust the position of each inserting plate in the toothed movable plate 3 and the inserting plate in the slot plate assembly in order to achieve The required undulation angle and size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com