Vacuum fixed sandy soil dry loading sample preparation apparatus and method for applying same

A fixed, vacuum technology, applied in the field of geotechnical triaxial test sample preparation, can solve the problems of easy dislocation, easy disturbance of the sample, large fastening force, etc., to improve stability and uniformity, meet the Sand sample preparation requirements, the effect of eliminating drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

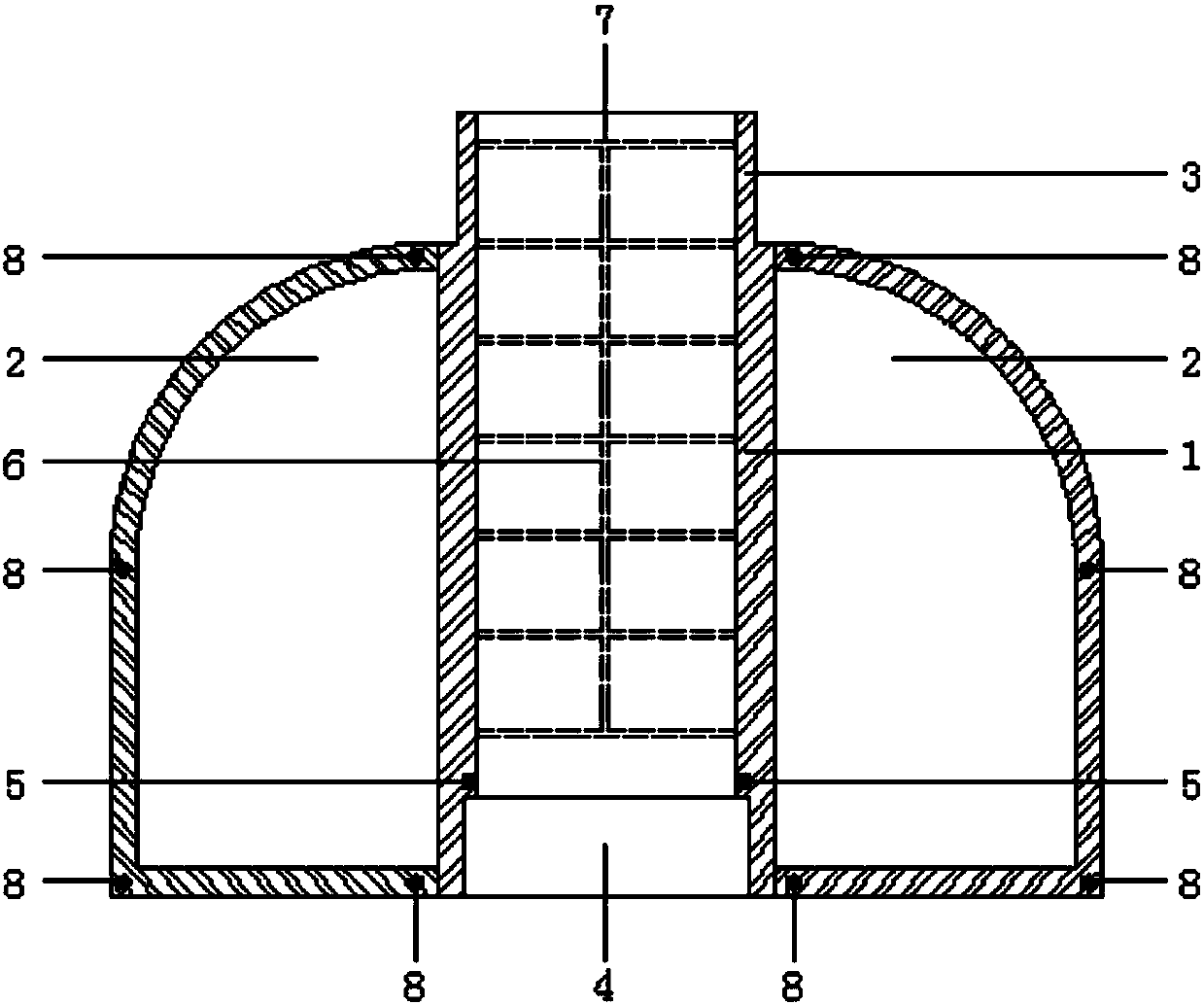

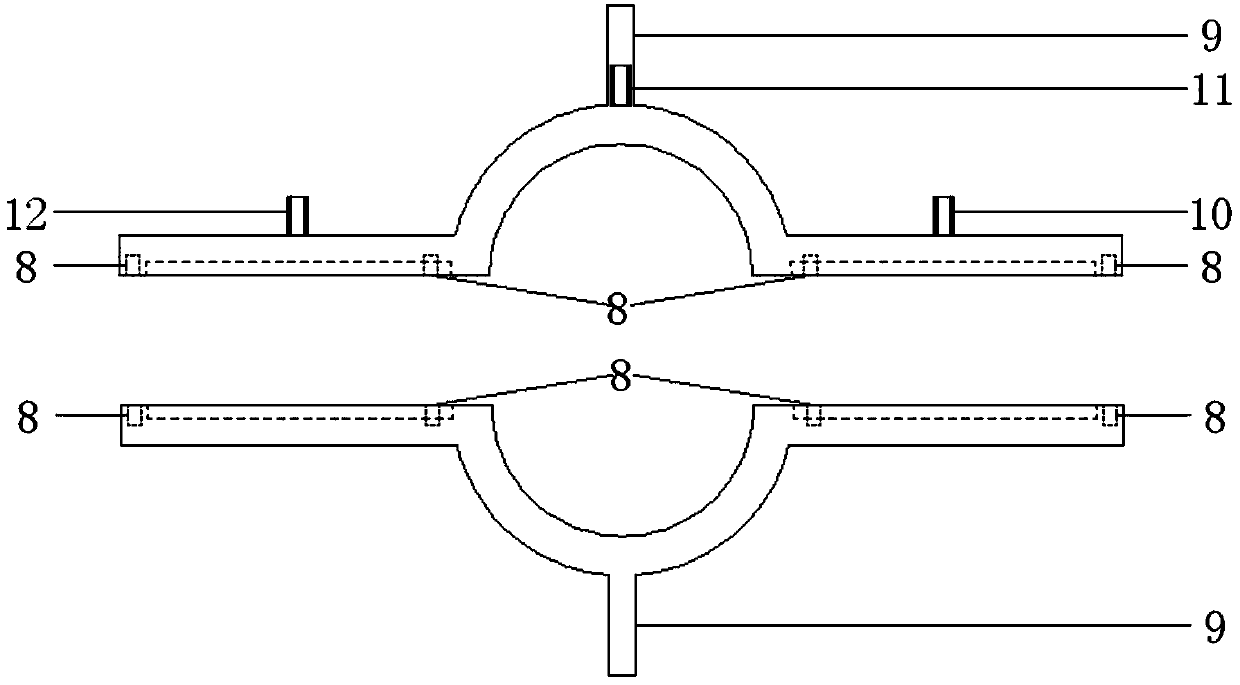

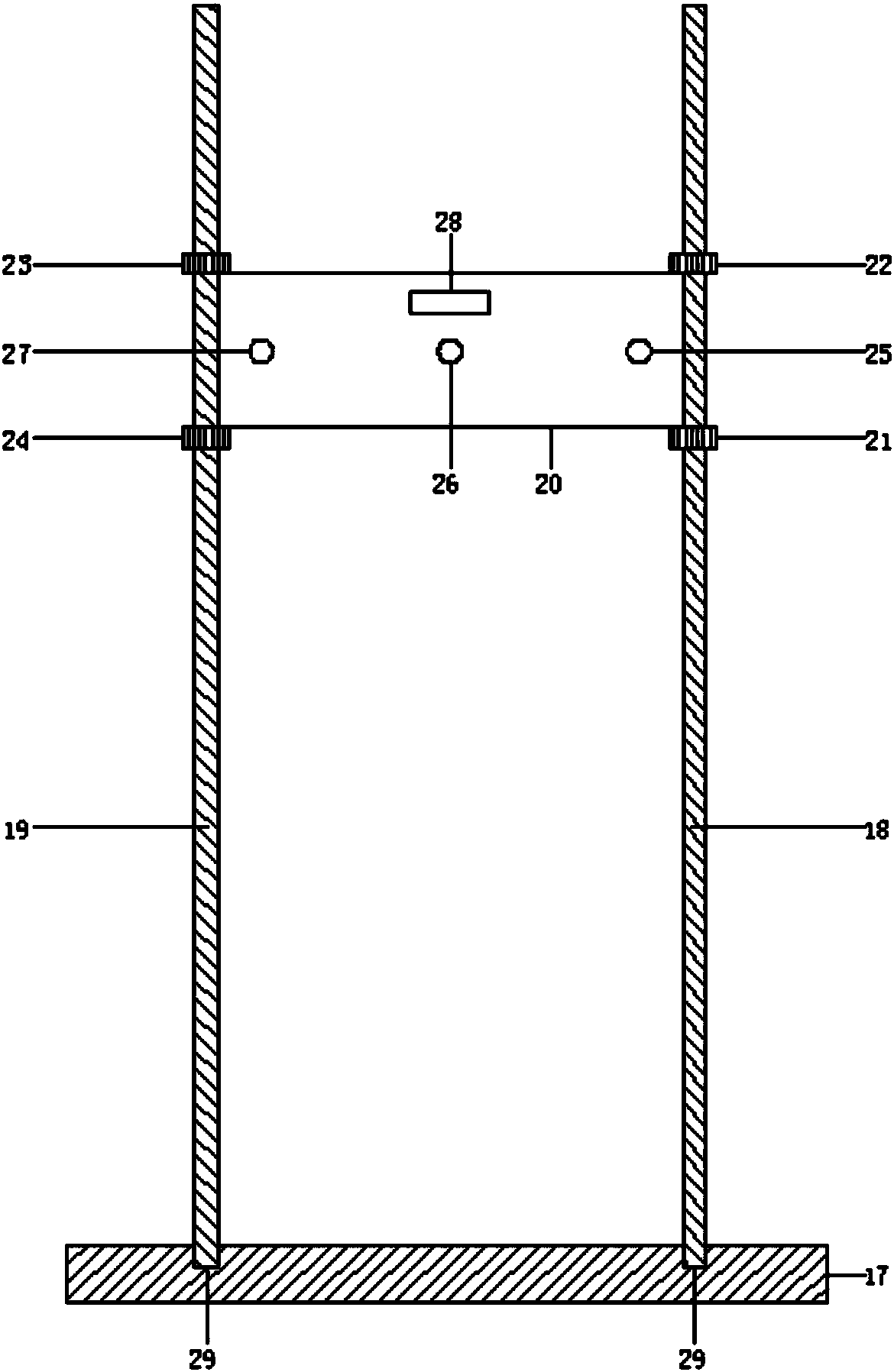

[0026] refer to Figure 1-4 , the present invention is a vacuum fixed sand dry sample preparation device, which includes a wing-type split film support tube, a liftable pipeline stabilizer and a vacuum console;

[0027] The wing-type split film tube includes a split mold 1, a hollow wing 2 and a stable delta wing 9;

[0028] The split mold 1 is a semi-cylindrical body, and the two split molds 1 are combined into the main cavity structure of the wing-type split film-bearing cylinder; the top of the split mold 1 is provided with a film-bearing platform 3, and the bottom is a containment cavity 4. The containment chamber 4 is sealed by the adjustable sealing strip 5; a plurality of circumferential exhaust grooves 7 and a plurality of longitudinal exhaust grooves 6 are arranged horizontally and evenly in the wing-type split membrane tube, and the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com