Combined type copper bar processing bench

A processing table and combined technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of increased procurement and manufacturing costs, high copper bar transfer times, and low work efficiency, so as to save transfer time, Effects of saving costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

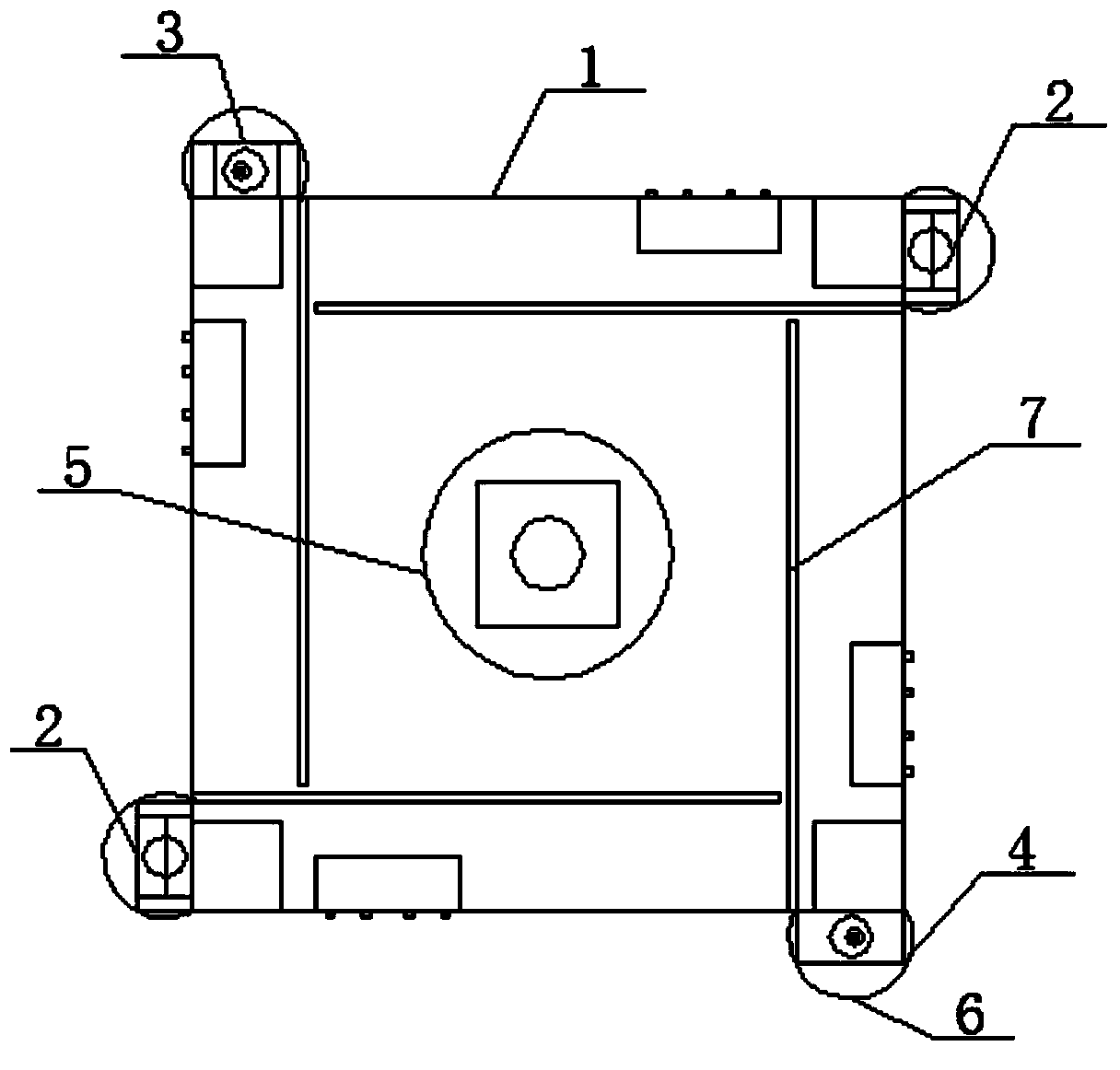

[0012] Such as figure 1 A combined copper bar processing table, comprising a square table main body 1, two punching work stations 2, a bending work station 4 and a piercing work station corresponding to the four corners of the workbench main body 1 position 3; the punching work position 2, the bending work position 4 and the breaking work position 3 are all equipped with a hydraulic cylinder 6 and a mold for completing the corresponding work driven by the hydraulic cylinder 6, and a hydraulic pressure cylinder is provided inside the workbench main body 1 Pump 5, the hydraulic pump 5 is connected with each hydraulic cylinder 6 through a hydraulic pipe to provide power oil for the hydraulic cylinder 6, and an embedded meter ruler 7 is provided at each working position as a reference object for the positioning and processing of the copper bar workpiece . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com