Electrical connector and manufacturing method thereof

A technology of electrical connectors and manufacturing methods, which is applied in the direction of connection, manufacture of contact box/base, parts of connection devices, etc., can solve the problems of up and down displacement, easy to produce deviation, little change in height, etc., and achieve assembly Stable and guarantee the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

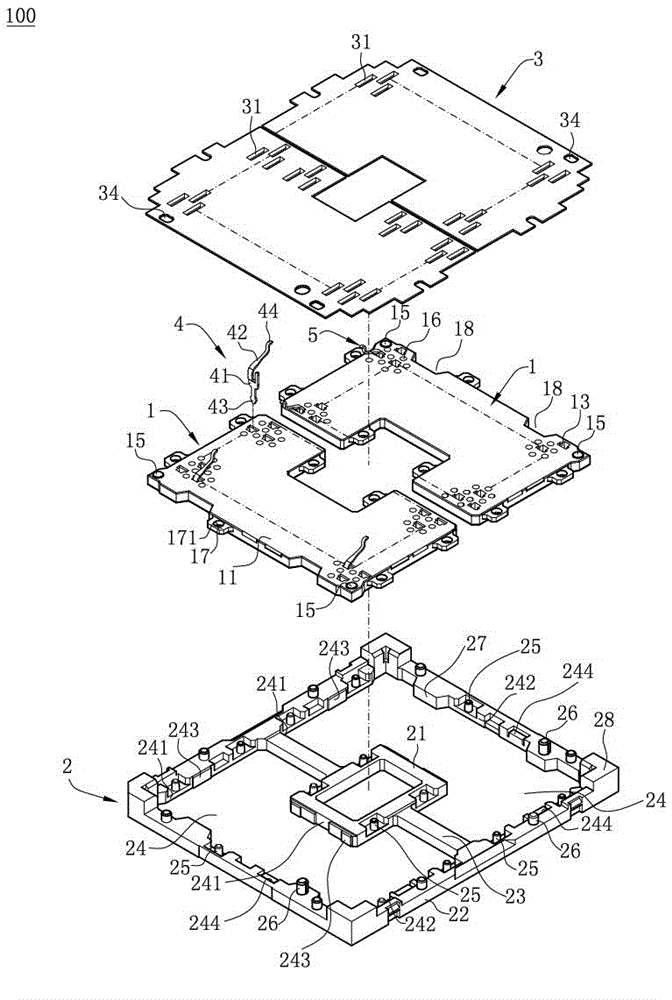

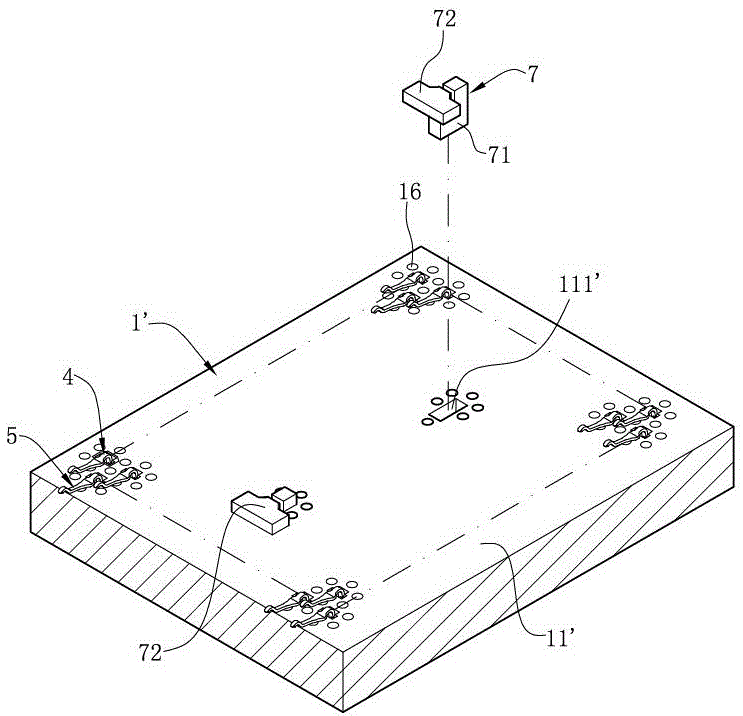

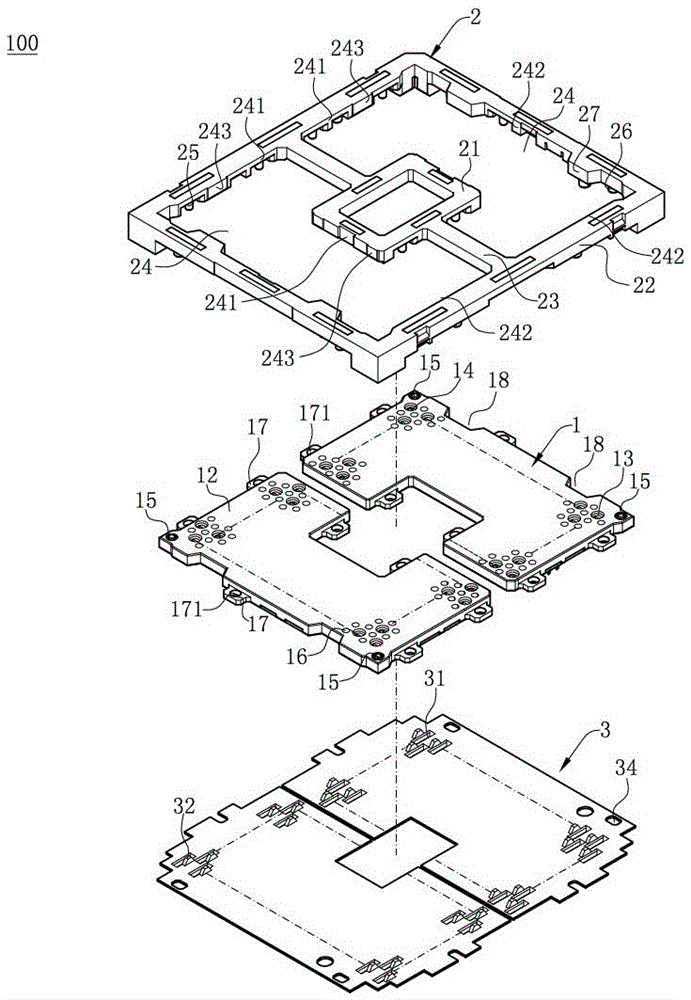

[0044] Such as figure 1 and figure 2 As shown, the electrical connector 100 of the present invention is used to electrically connect a chip module (not shown), and includes at least one body 1, each of which has an upper surface 11 and a lower surface 12, and is flat plane. In this embodiment, there are two bodies 1 , and in other embodiments, there may be one or more bodies 1 . A frame body 2 , the frame body 2 has at least one accommodation area 24 , the body 1 is located in the accommodation area 24 and fixed with the frame body 2 . A support cover 3 is assembled to the frame body 2 and covered on the body 1, the bottom surface of the support cover 3 is higher than the upper surface 11, the chip module is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com