Energy-saving and high-efficiency incubator

A high-efficiency, single-chip microcomputer technology, applied in poultry incubators, climate change adaptation, poultry industry, etc., can solve the problems of geographical and structural restrictions, uneven temperature and humidity distribution in the box, and achieve considerable economic benefits, increase hatching rate, and over-temperature The effect of phenomenon reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

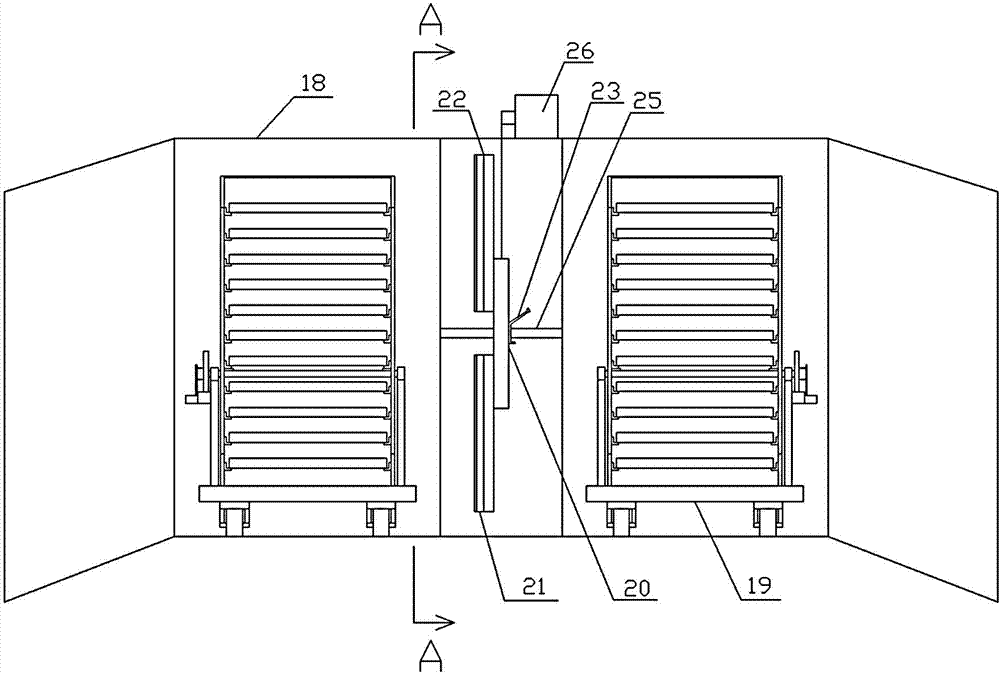

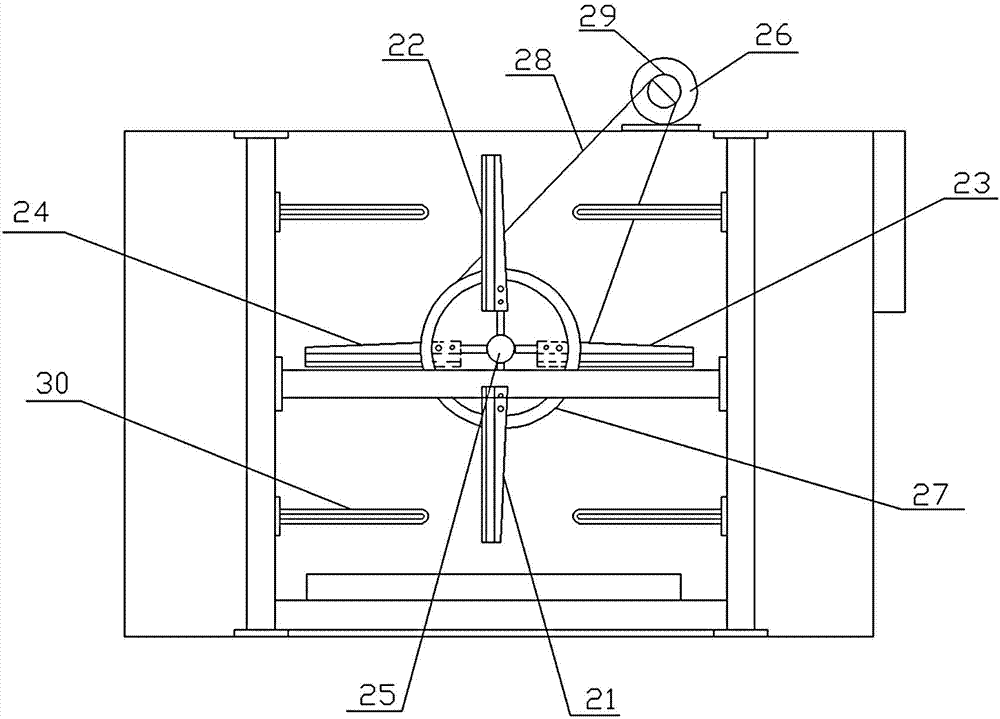

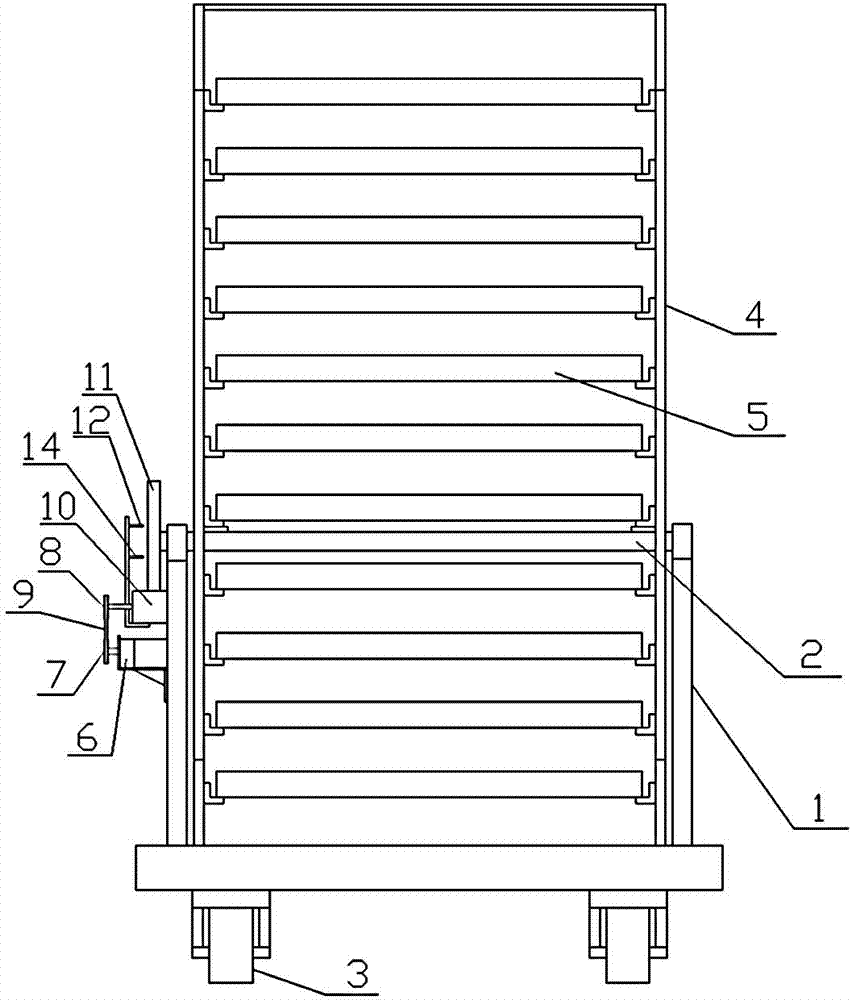

[0019] Such as figure 1 As shown, the energy-saving and high-efficiency incubator provided by the present invention includes an incubator box 18, an egg cart 19 and a fan 20; figure 2 As shown, the two sides of the fan blade disc 27 of the fan 20 are respectively provided with blades with different wind directions, and two blades are respectively provided on each side. The fan blades 22 are mutually 180°, and the third fan blade 23 and the fourth fan blade 24 are mutually 180°; the fan blades on both sides are perpendicular to each other, namely the first fan blade 21, the third fan blade 23, and the second fan blade 22 and the fourth fan blade 24 are mutually 90° in turn; the output shaft of the motor 26 is assembled and connected with the fan blade 27 through the fan pulley 29 and the fan belt 28, so that the fan blade 27 drives the fan to rotate along the rotating shaft 25; set in the incubator The heating tube 29 in the body 18 is responsible for heating during incubat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com