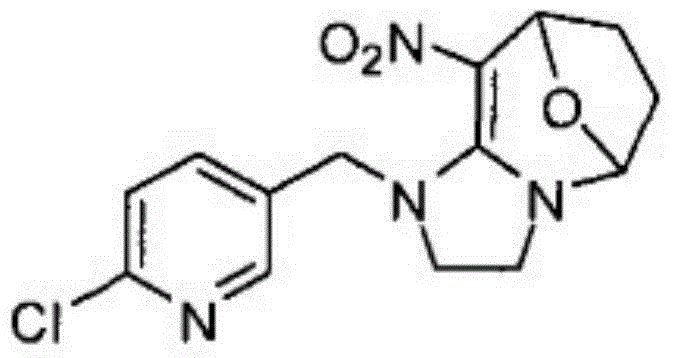

Ultra-low-volume solutions containing cyclopyrid and carbamate insecticides

A carbamate-based, ultra-low-volume liquid preparation technology, applied in the field of pesticides, can solve problems such as pesticide residues, pest resistance, environmental pollution, etc., and achieve the effects of reasonable components, synergistic effects, and low drug costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

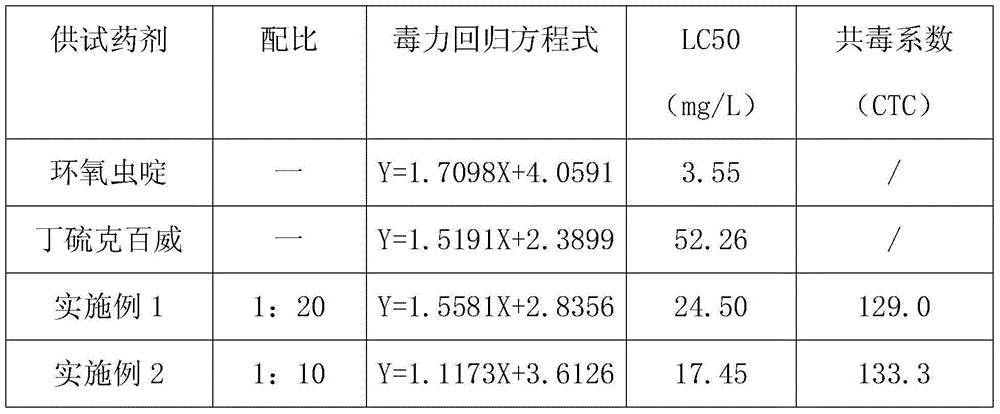

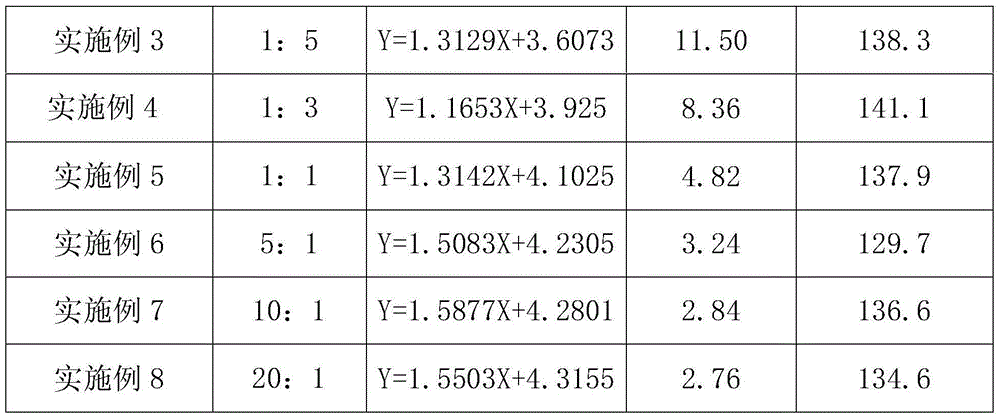

Examples

Embodiment 1

[0029] Example 1 21% Cyclopyrid Carbosulfan Ultra-Low Volume Liquid (1:20)

[0030] Cyclopyrid 1kg, carbosulfan 20.0kg, N,N-dimethylformamide 13.0kg, methylnaphthalene 5.0kg, o-dichlorobenzene 3.0kg, castor oil polyoxyethylene ether 1.0kg, second-line oil Make up to 100kg, and mix to prepare 20.1% cyclopyrid-carbsulfur ultra-low volume liquid.

[0031] Preparation process: In a stirred reaction vessel, first use a solvent to stir and dissolve epoxypyrid and carbosulfan, then add auxiliary components, stir and mix evenly to obtain 20.1% epoxypyrid-butyl Carbofuran ultra-low-capacity liquid agent; the process parameters are: the stirring speed is controlled at 60-150 rpm, the stirring time is 15-60 minutes, the temperature is normal temperature, and the pressure is normal pressure.

[0032] According to the same preparation process steps as in Example 1, the following examples can be prepared.

Embodiment 2

[0033] Example 2 22% Cyclopyrid Carbosulfan Ultra-Low Volume Liquid (1:10)

[0034] Cyclopyrid 2.0kg, carbosulfan 20.0kg, N,N-dimethylacetamide 10.0kg, N-methylpyrrolidone 9.0kg, n-hexanol 5.0kg, turpentine 4.0kg, methylpropylbenzene 10.0 kg, 3.0kg of alkylphenol polyoxyethylene ether, 3.5kg of alkylaryl polyoxypropylene polyoxyethylene ether phosphate ester, 3.5kg of alkylaryl polyoxypropylene polyoxyethylene ether, and cottonseed oil to make up to 100kg, mixed to prepare 22% Cyclopyrid · Carbosulfan ultra-low volume liquid.

Embodiment 3

[0035] Example 3 30% Cyclopyrid Carbosulfan Ultra-Low Volume Liquid (1:5)

[0036] Cyclopyrid 5.0kg, carbosulfan 25.0kg, N,N-dimethylformamide 5.0kg, N-methylpyrrolidone 4.0kg, acetophenone 10.0kg, methyl oleate 8.0kg, dodecyl Calcium alkylbenzene sulfonate 2.0kg, phenylethylphenol polyoxyethylene ether phosphate 3.0kg, fatty alcohol polyoxyethylene ether 2.0kg, soybean oil make up to 100kg, mix to prepare 30% epoxyclopyr-butasulfone Budweiser Ultra Low Volume Liquid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com