Breather valve structure

A breathing valve and valve cover technology, which is applied in the direction of respiratory protection devices and life-saving equipment, can solve the problems of insufficient welding fastness between the breathing valve and the respirator or filter mask body, low degree of automatic assembly, and insufficient breathing, and achieve outstanding results. Substantial features, reasonable design structure, easy welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

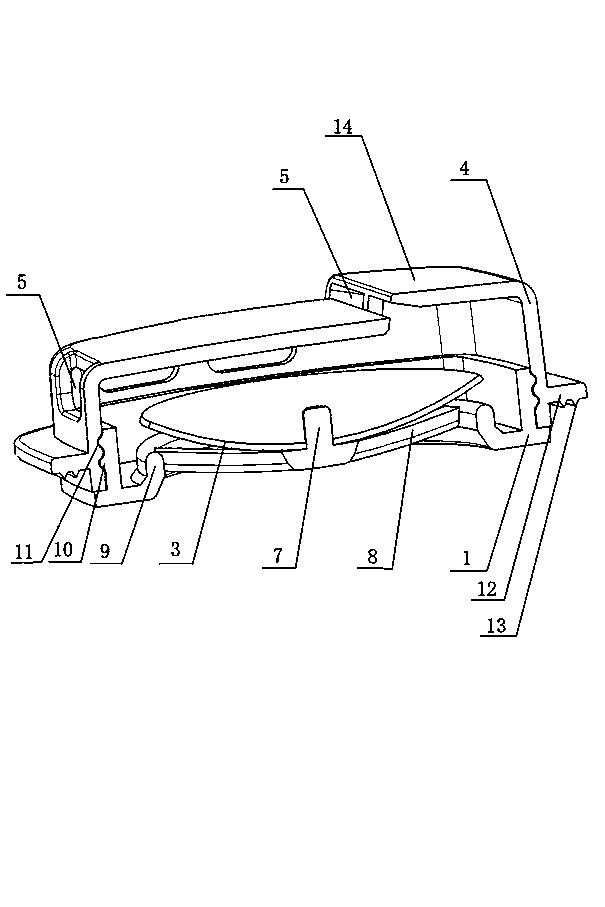

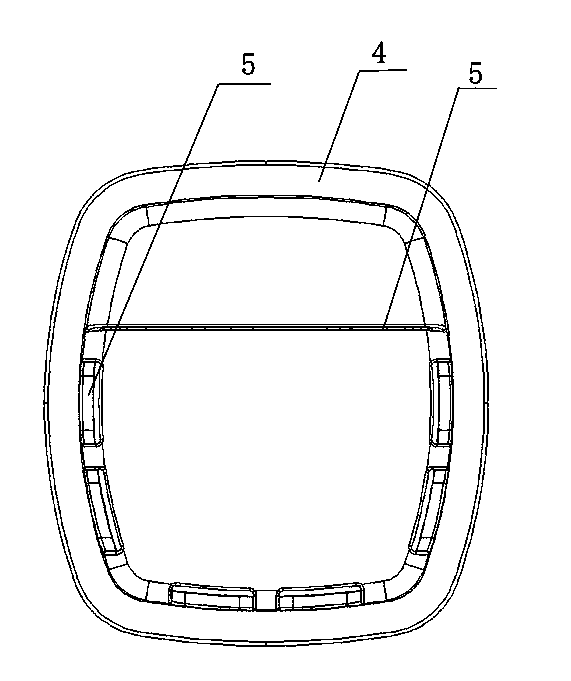

[0015] The invention discloses a breathing valve structure, which includes a base 1, which is different from the prior art in that: the surface of the base 1 is provided with a valve hole 2, and the inside of the valve hole 2 of the base 1 is covered with a diaphragm 3, and the base 1 Connected with the valve cover 4, a hollow cavity is formed between the base 1 and the valve cover 4, and an exhaust port 5 is opened at the valve cover 4.

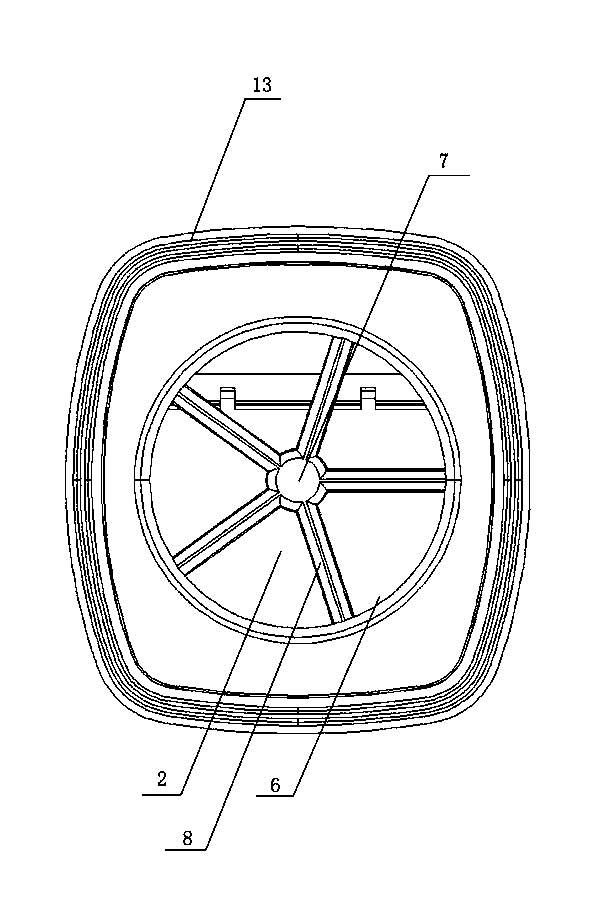

[0016] During specific implementation, the surface of the base 1 is provided with a circular hole 6, and the center of the circular hole 6 is provided with a diaphragm 3 fixing column 7, and a gap between the diaphragm fixing column 7 and the inner edge of the circular hole 6 There are support bars 8, and the diaphragm fixing column 7 is divergent to the surrounding. There are 3-9 support bars 8, and each support bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com