Laser-tube welding

A technology of laser welding and laser head, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., to achieve the effect of reducing the time for reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

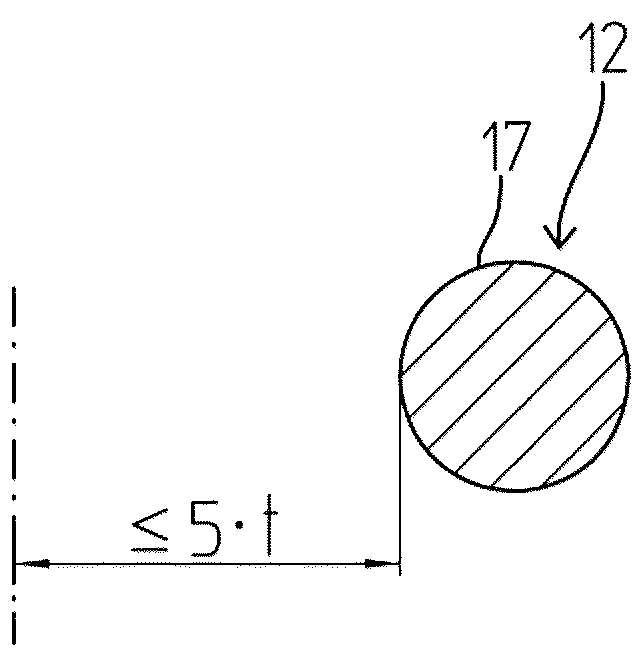

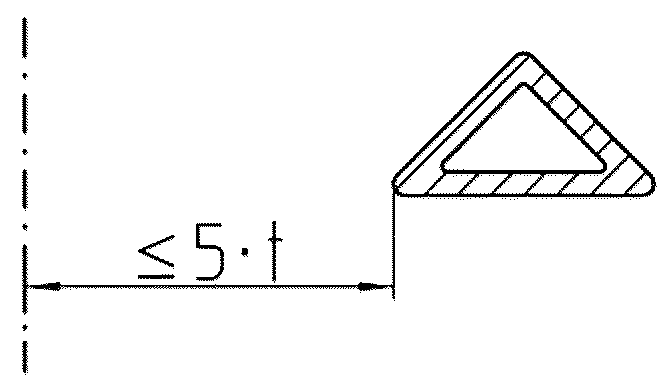

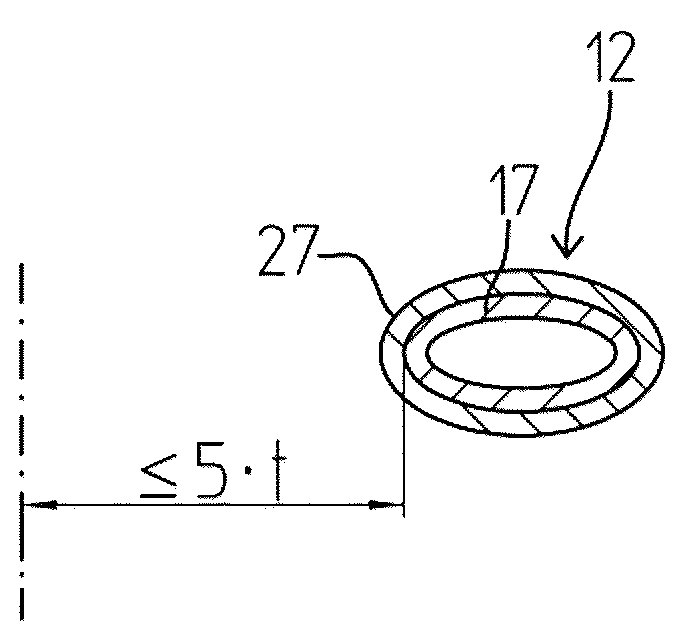

[0104] exist figure 1 , 2a The exemplary embodiment of the device 1 according to the invention shown in and 2b is arranged in front of the pipe base 2 which is oriented vertically in the example shown, for carrying out the method according to the invention.

[0105] The device 1 has a laser head 3 with a guide lens 4 . The laser head 3 is designed to emit a laser welding beam 5 and is preferably a fiber laser, which is connected to a laser generator LG by means of an optical fiber 6 . By decoupling the laser generation from the laser optics, the laser head 3 can be implemented with a low weight. This enables less latency and precise movement.

[0106] Preferably, the laser head 3 is fixed, as in the illustrated embodiment, on a swivel device 7 ; it is set up to guide the laser head 3 on a circumferential line 8 , which runs parallel to the tube bottom surface 9 . Using the rotary device 7 , the laser head 3 can be moved in polar coordinates about the axis of the tube 10 , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap