Unidirectional movement mechanism for mini-tiller part machining

A technology of parts processing and motion mechanism, which is applied in the field of one-way motion mechanism for micro-tiller parts processing, can solve the problems of poor processing cooling effect and unfixed intermittent frequency of manual operation, etc., and achieves good processing cooling effect, simple structure, The effect of reducing the cantilever length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

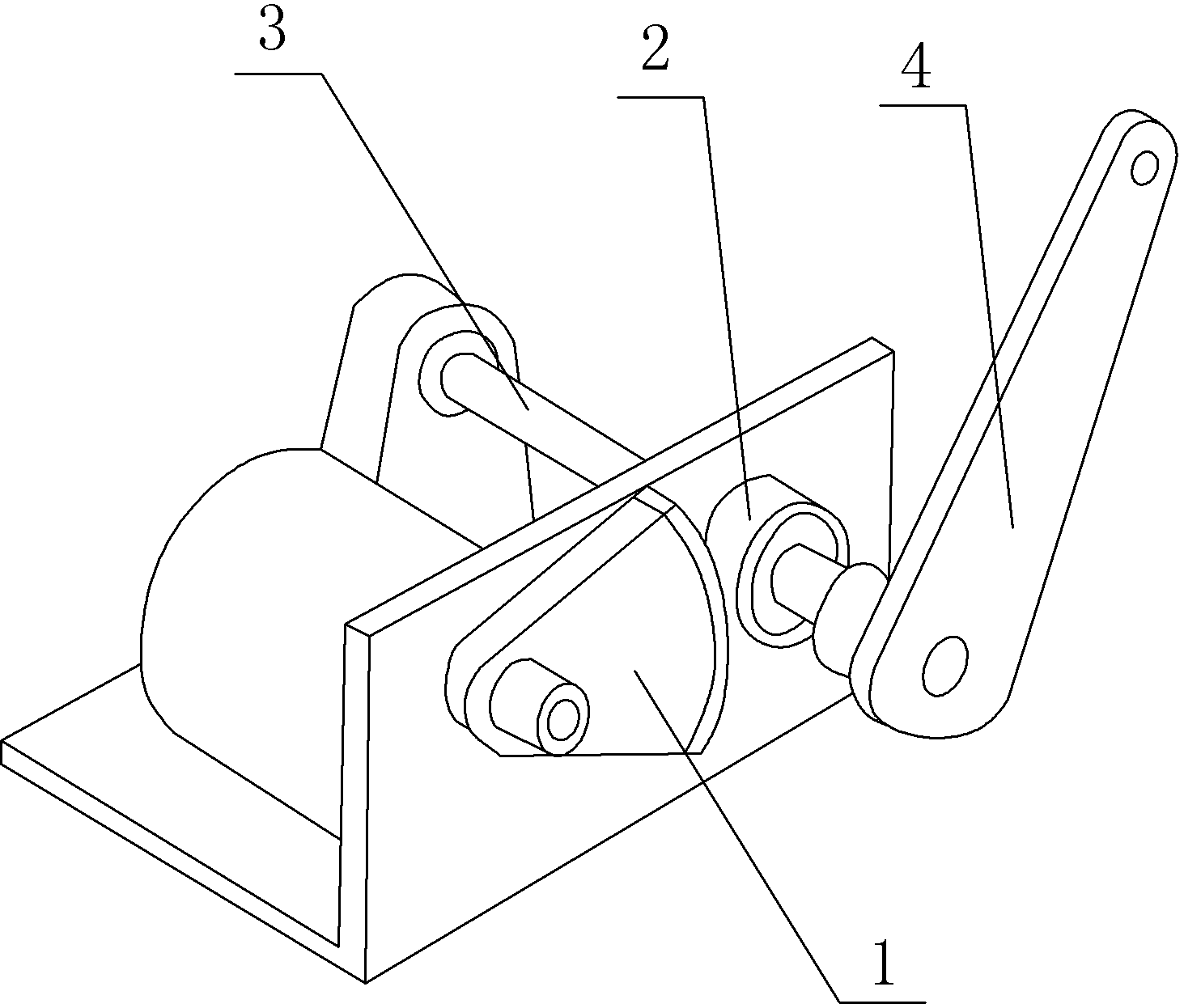

[0009] according to figure 1 As shown, the one-way motion mechanism for the processing of tiller parts in the embodiment of the present invention includes a frame, and is characterized in that it also includes a sector gear 1 that is rotatably connected to the frame, a transmission tooth 2 that meshes with the sector gear 1, and The driven shaft 3 connected to the transmission gear 2 through a single bearing, one end and the middle part of the driven shaft 3 are connected to the frame through bearings, the other end of the driven shaft 3 is threaded with a telescopic swing arm 4, and the transmission gear 2 includes the left half The end faces of the part and the right half, the left half and the right half are provided with inverted tapered projections and inverted tapered slots.

[0010] What is described above is only an embodiment of the present invention, and common knowledge such as specific structures and characteristics known in the scheme are not described here too mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com