Roller lathe center frame

A roll lathe and center frame technology, applied in the field of roll lathe center frames, can solve the problems of increased processing costs, low pass rate, and wear of support claws, and achieve the effect of convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

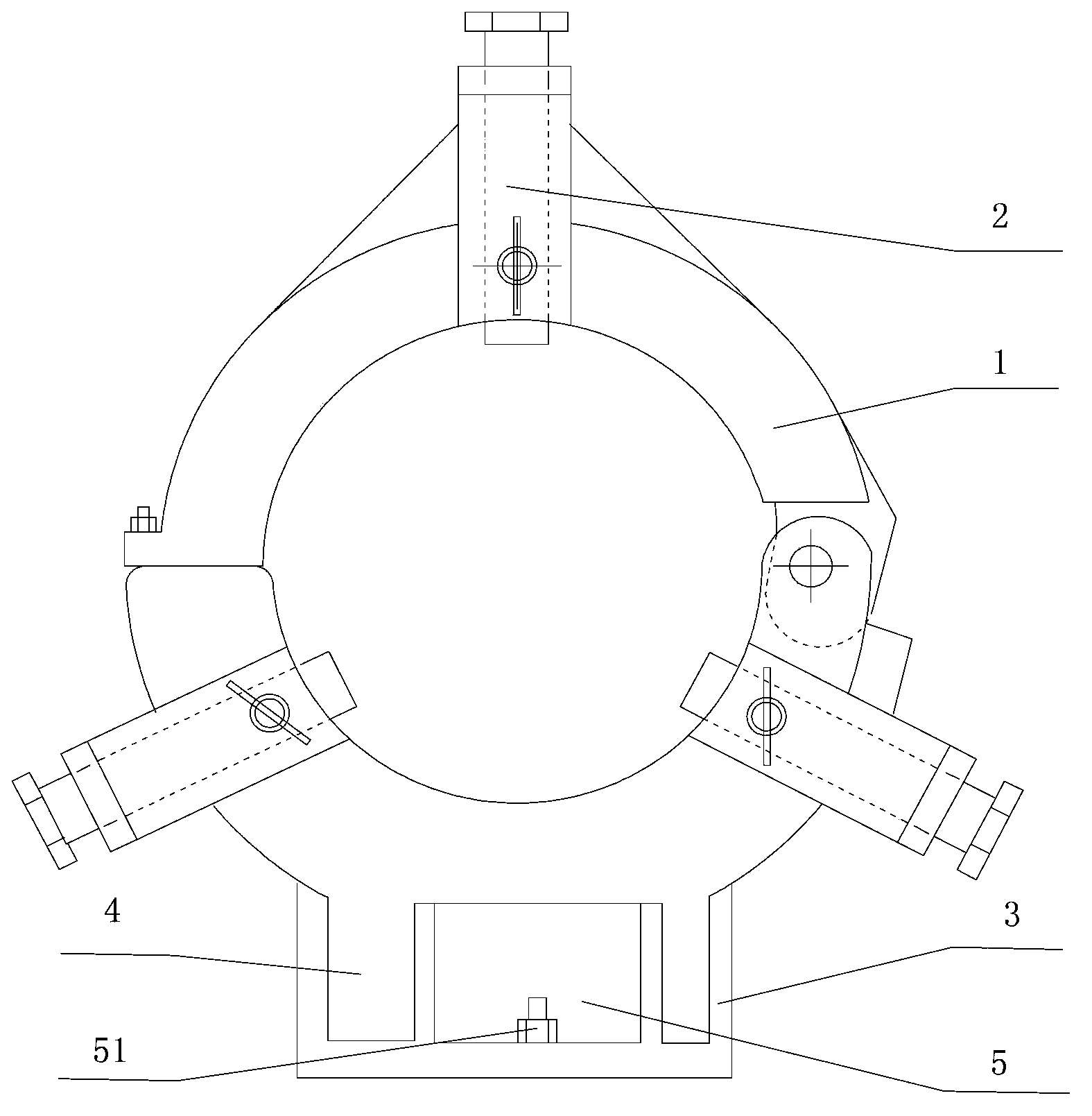

[0010] See figure 1 As shown, a roll lathe center frame includes a ring frame 1, and three radially expandable support rods 2 are arranged on the inner ring of the ring frame 1. It also includes a base 3, and the base 3 and the ring frame 1 The lower end surface is fixedly connected, and the reinforcing rib 4 is fixedly connected between the base 3 and the ring frame 1; the base 3 is provided with a groove 5, and the groove 5 is provided with a bolt 51 for fixing with a lathe.

[0011] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com