Workbench with flip function

A workbench, functional technology, applied in workbenches, manufacturing tools, etc., can solve the problems of slow turning speed, scratches, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

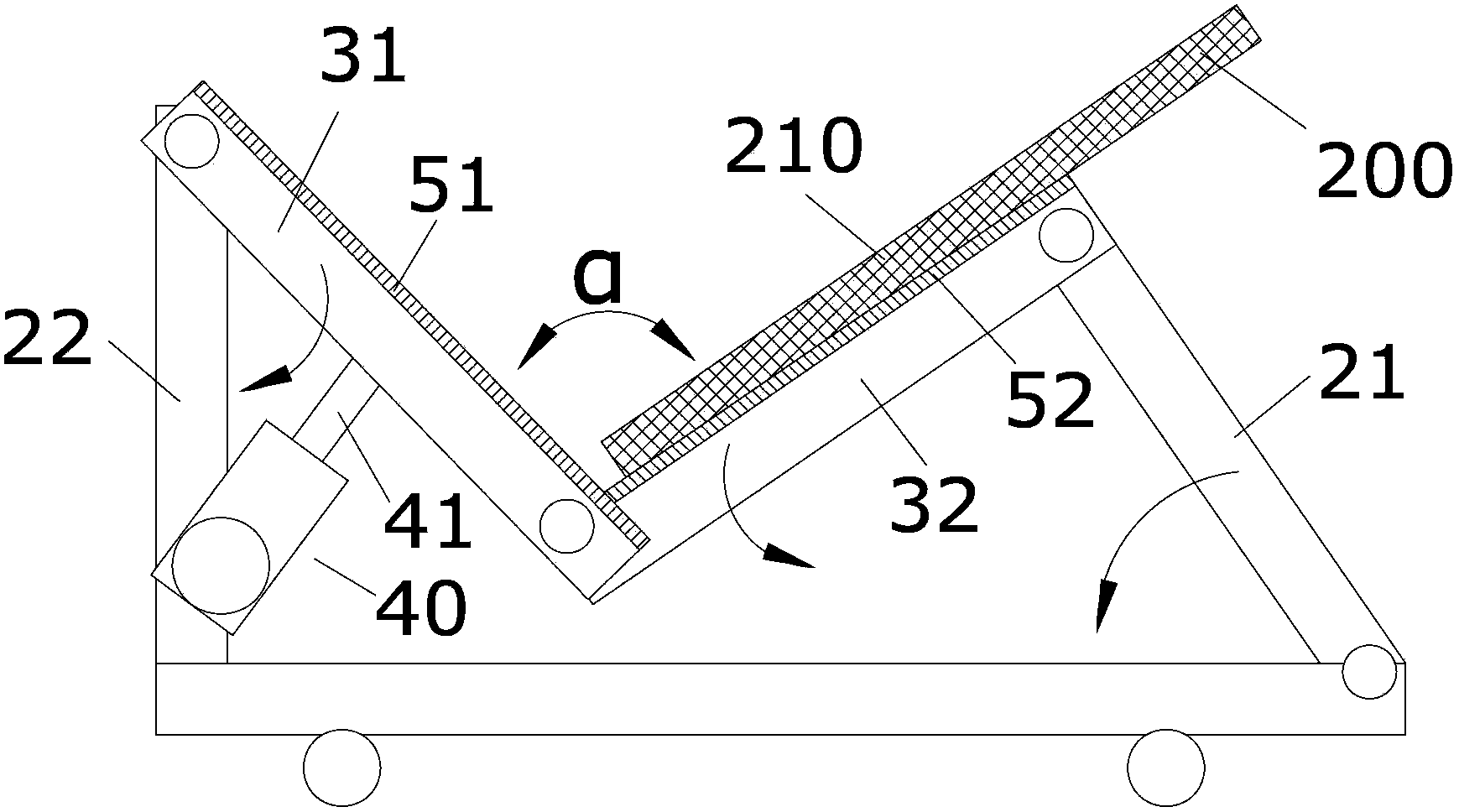

[0028] As mentioned in the background art, with the development of LCD technology, in order to obtain good coating quality, the area of the target material for LCD is also increasing. However, due to factors such as the size of the large-area target and its own weight, it is difficult to flip in the welding, sandblasting, packaging and other processing steps. Not only the flipping process is slow, but also deformation and scratches are prone to occur, which affects welding, The quality of processes such as sandblasting will affect the quality of the target material and ultimately the quality of the LCD coating.

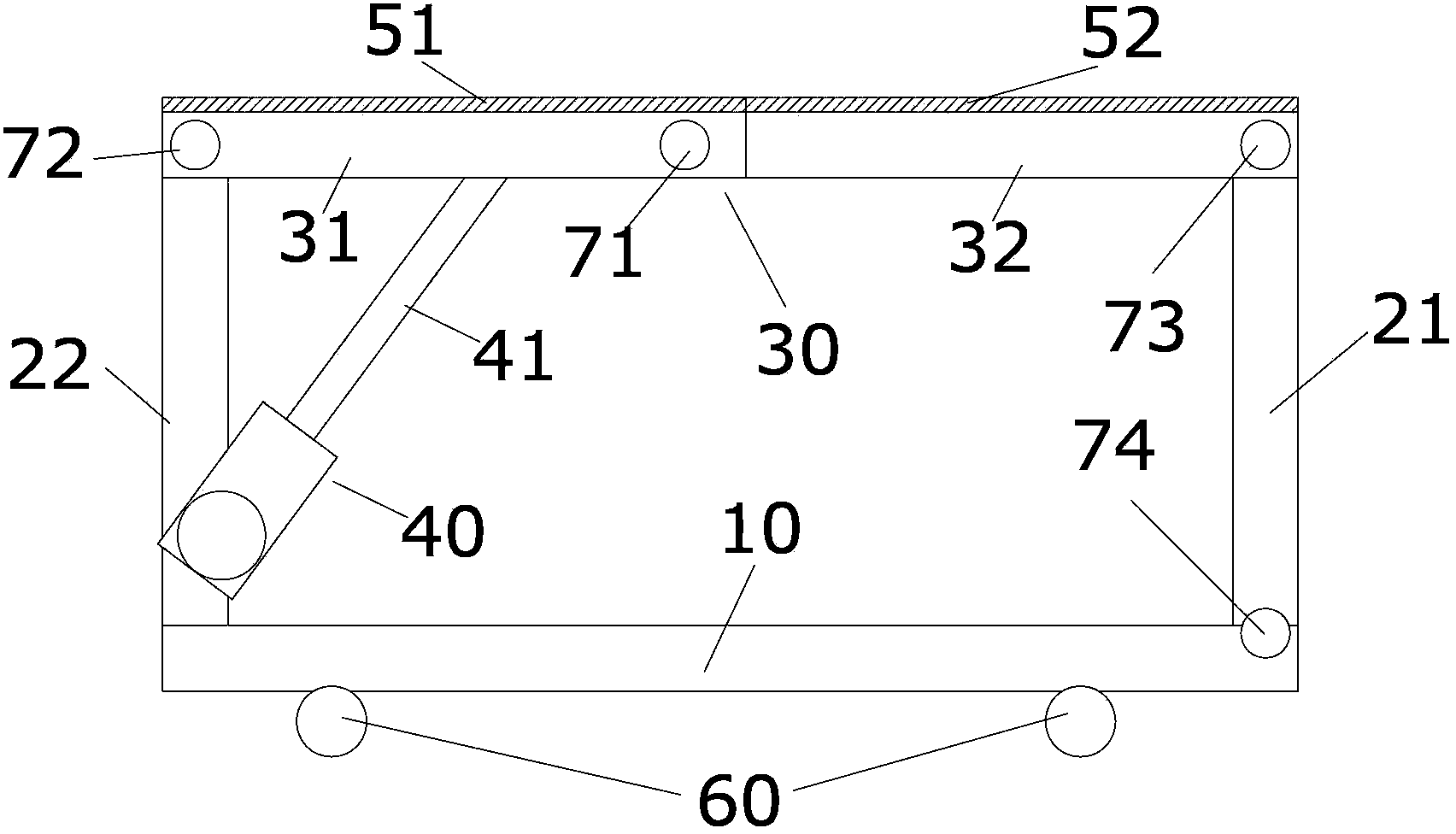

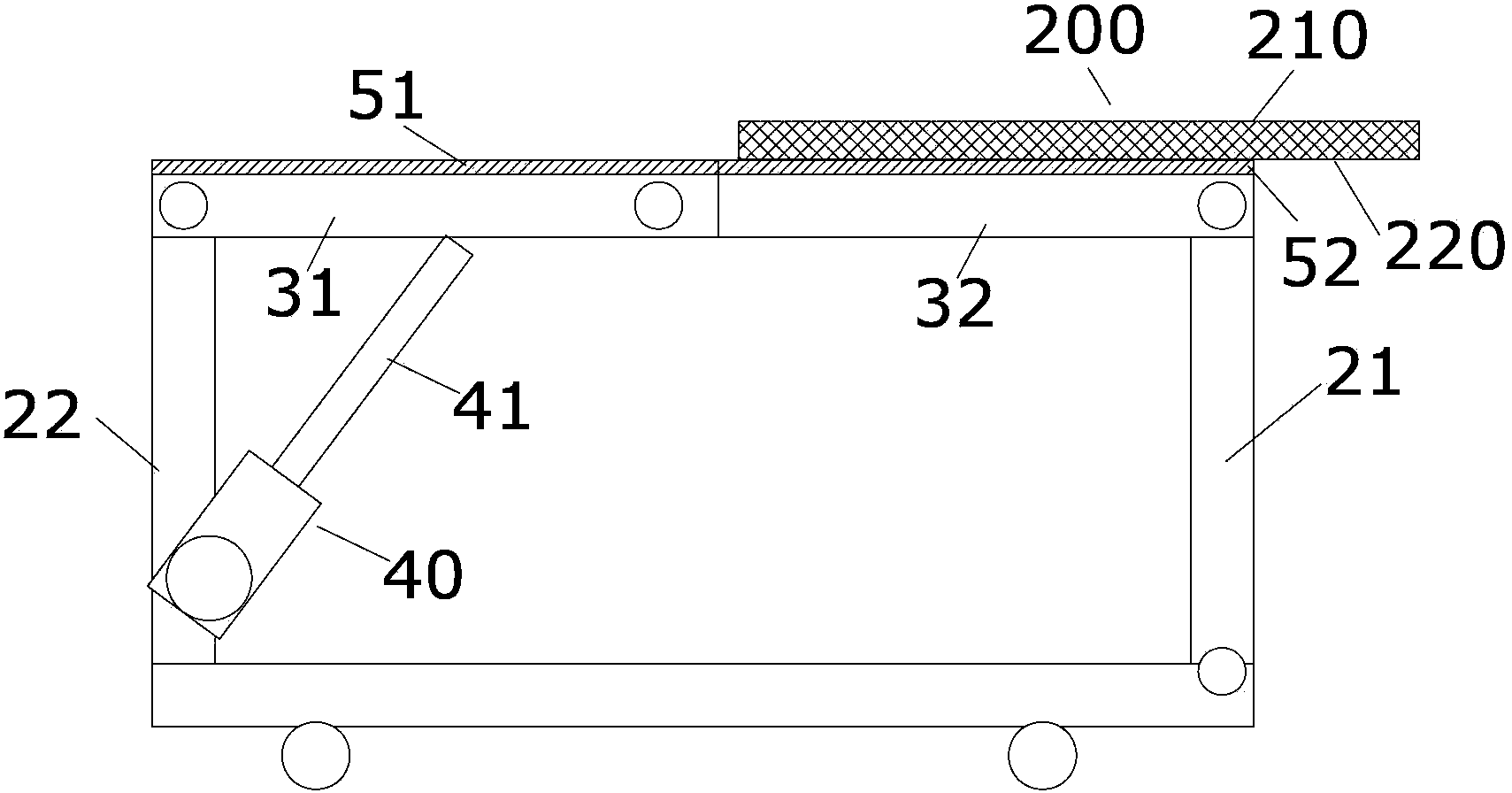

[0029] To this end, the present invention provides a workbench with a turnover function, which includes a base, a support column whose lower end is fixed on the base, and a turnover plate arranged at the upper end of the support column and used to turn the target substrate. The turning plate includes two supporting plates, and the adjacent ends of the two supporting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com