Bin cleaning mechanism of full-automatic foam plate machine

A fully automatic, silo-based technology that is applied to flat products, household appliances, and other household appliances. It can solve problems that do not meet production requirements and plate mixing, and achieve the effects of simple structure, low processing cost, and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

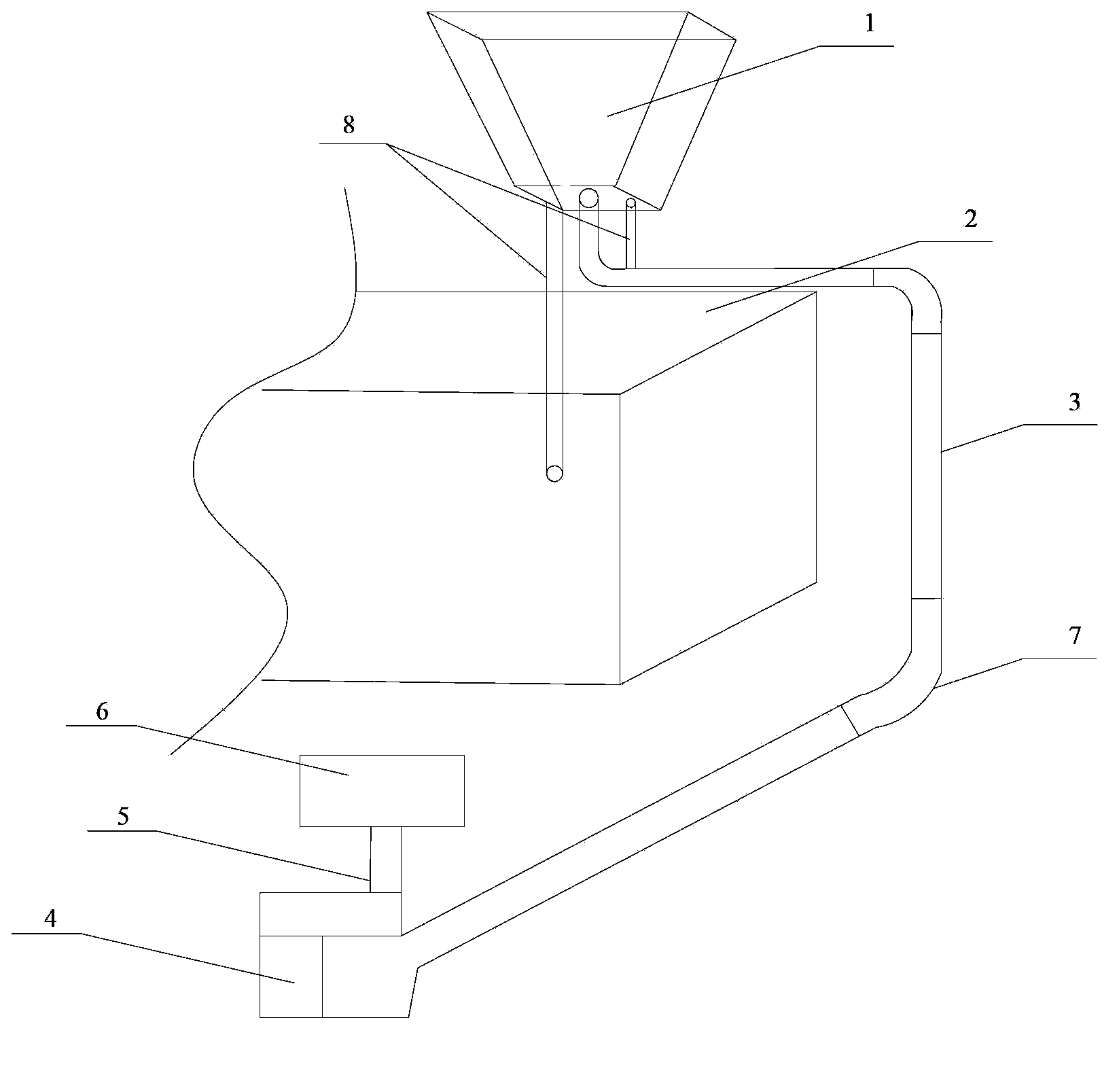

[0013] Such as figure 1 As shown, the present invention provides a bin cleaning mechanism for a fully automatic foam board machine, including a feed bin 1 and a trigger body 2, and the feed bin 1 on the trigger body 2 is also provided with a fan duct 3; The tail of the fan pipe 3 is connected to the fan 4, and the discharge port 5 of the fan 4 is connected to the collecting box 6. The number of the fan duct 3 is at least one. The fan pipe 3 is a multi-section straight pipe connected sequentially through a turning connector 7 .

[0014] The working process of this example: when the trigger is working, the raw material in the feed bin 1 enters the trigger body 2 through the trigger feed pipe until it reaches the amount required by the production process, close the trigger feed pipe 8, and then add it to other processes The required materials are used for the production of insulation boards. When all the raw materials in the feed bin 1 are used up, at this time, if the next pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com