Heart valve type screw rod for color masterbatch production

A heart-shaped, color masterbatch technology, applied in the field of color masterbatch production heart-shaped screw, can solve the problems of unsatisfactory high-end products, poor dispersion, insufficient screw pressure and shear force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the present invention, the present invention will be further described below through specific examples. However, the invention is not limited thereby.

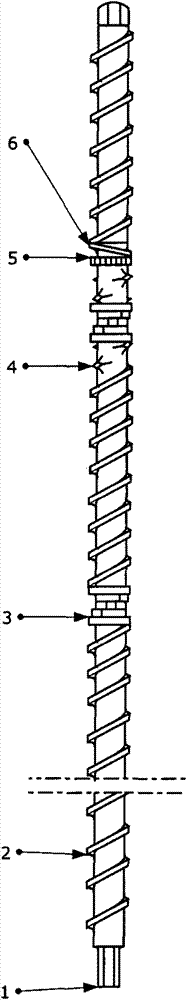

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown is a high-pressure, high-shear screw structure diagram, which has a screw mandrel (1), a threaded element (2), an elliptical blending block (3), a heart-shaped kneading block (4), and a tooth type It consists of structural elements such as a mixing disc (5) and an anti-mixing helix (6). The material added from the feeding port is pushed by the conveying screw to the shearing and mixing element---the blending or kneading block, so that the material can be sheared, mixed and matured here, and the toothed mixing disc plays the role of blocking the material. Increase the pressure of the material in the front section to strengthen the shearing effect of the kneading block. Finally, the anti-mixing screw element plays the role...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com