Patents

Literature

30results about How to "Meet the needs of high-end products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

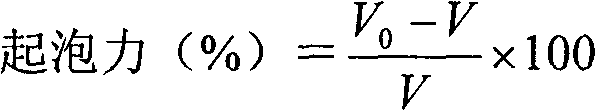

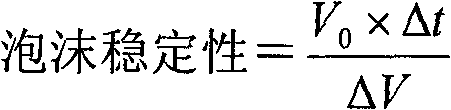

Egg white powder with high foamability and preparation method thereof

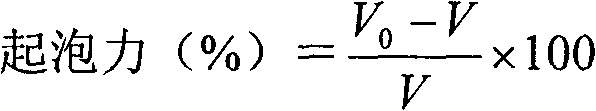

The invention provides egg white powder with high foamability and a preparation method thereof and relates to reconstruction of whey protein structure and functional properties, belonging to the technical field of biological processing of foodstuffs. According to the invention, on the basis of preliminary work, enzymatic hydrolysis of lipase in advance and cooperative enzymatic hydrolysis of composite protease are utilized for treatment of egg white; total usage amount of lipase and composite protease is less than usage amount of individually used lipase or protease, and however, foamability and foam stability of egg white powder obtained by combined utilization of lipase and composite protease are higher than those of egg white powder obtained by individual utilization of lipase or composite protease; the egg white powder obtained in the invention can meet demands for high-grade products on the market, and the advantages of a simple process and high cost performance are achieved in the invention. According to the invention, the ratio of active usage amount of Aspergillus oryzae protease, papain and trypsin is determined to be 1:1:1; the usage amount and other technological parameters cooperatively allow egg white powder with high foamability to be obtained; egg white powder with high foamability provided in the invention enables the additional output value of eggs to be increased, lays a technical foundation for development and industrial production of special-purpose egg white powder products and increases economic benefits for enterprises.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

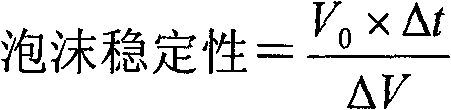

Grapheme composite membrane, preparing method thereof and functions thereof

InactiveCN103928076AImprove featuresGood flexibilityConductive materialNon-conductive material with dispersed conductive materialMaterials scienceGrapheme

The invention relates to a grapheme composite membrane, a preparing method thereof and functions thereof, and belongs to the field of conductive membranes. The grapheme composite membrane comprises a grapheme membrane body and a conductive enhancing membrane body, and has a good bending characteristic, flexibility, light transparency and conductivity.

Owner:2D CARBON CHANGZHOU TECH INC

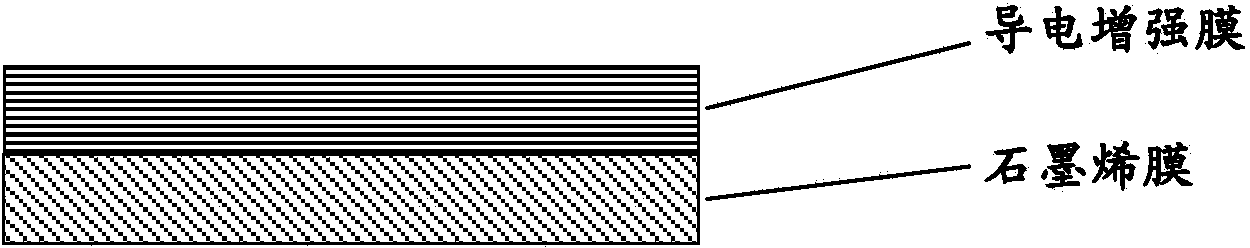

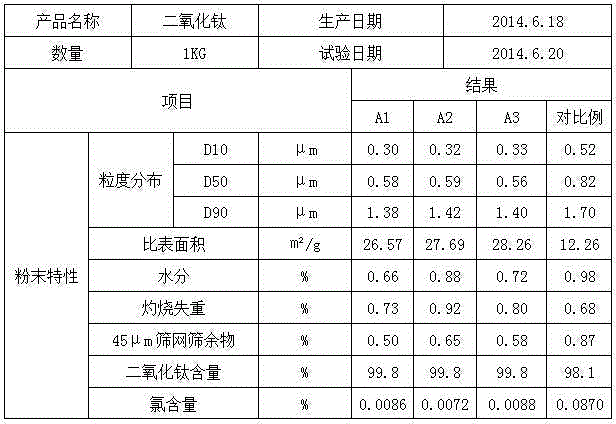

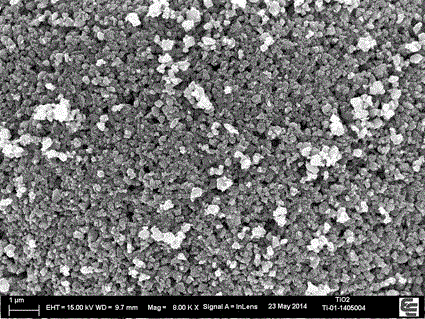

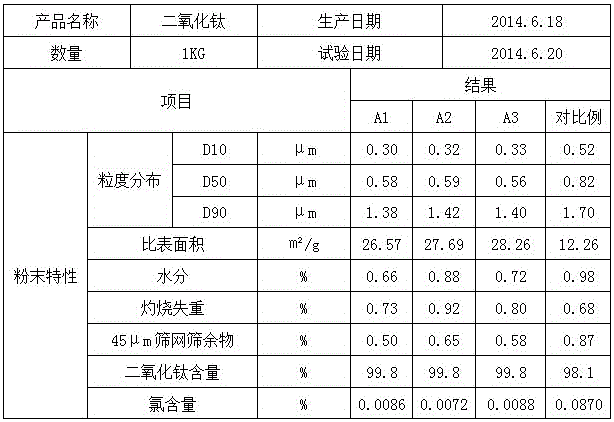

Preparation method of titanium dioxide with high specific surface area

ActiveCN104150531APrevent particle aggregationHigh specific surface areaTitanium dioxideIonTitanium tetrachloride

Owner:仙桃市中星电子材料有限公司

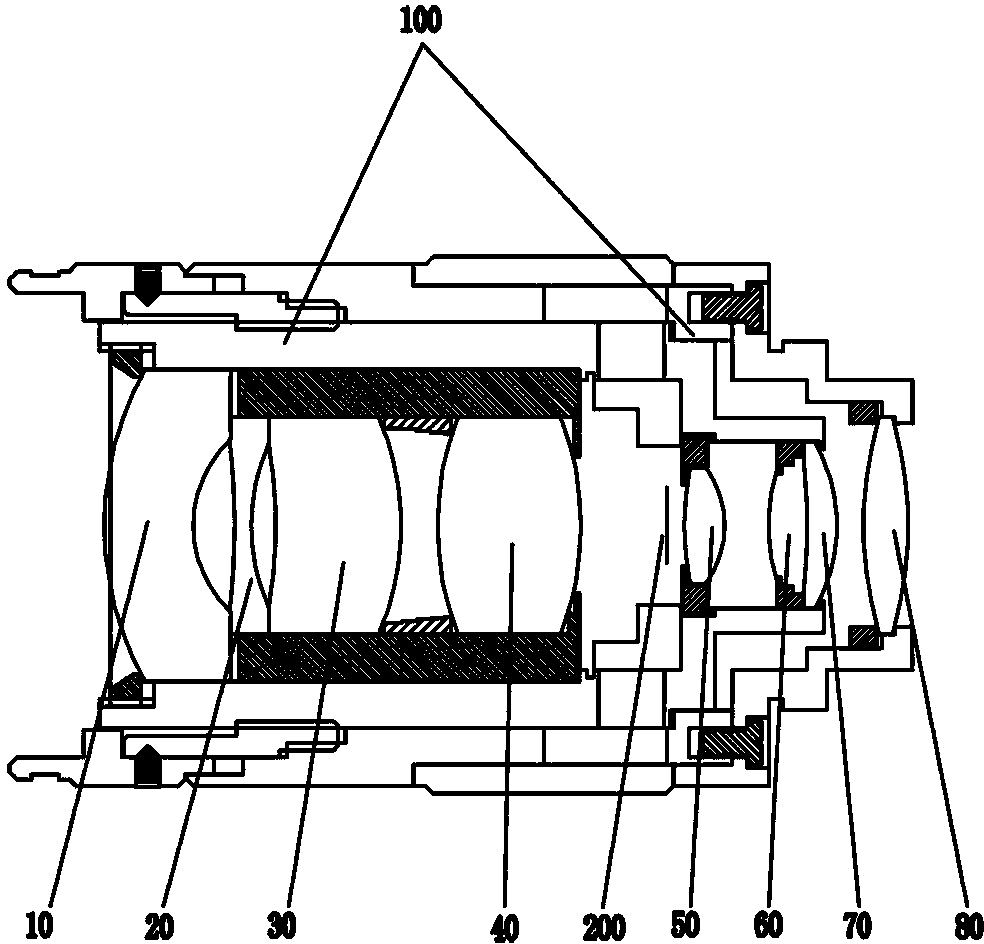

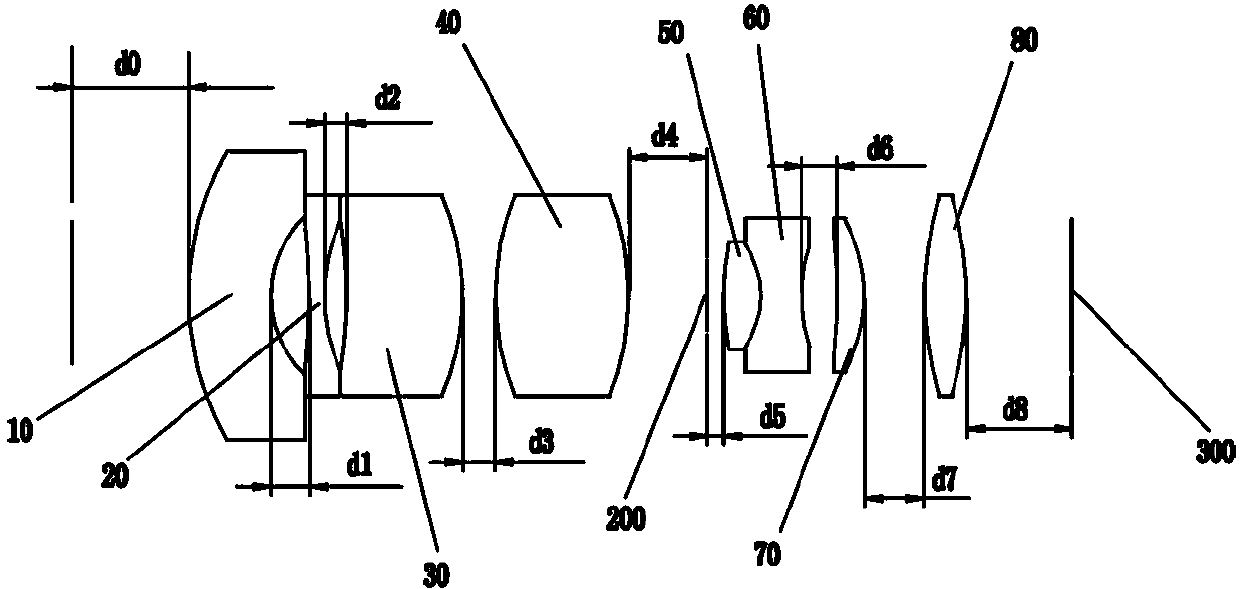

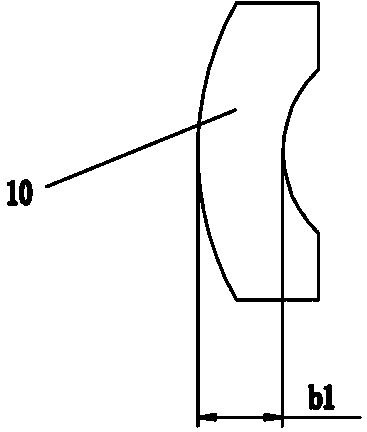

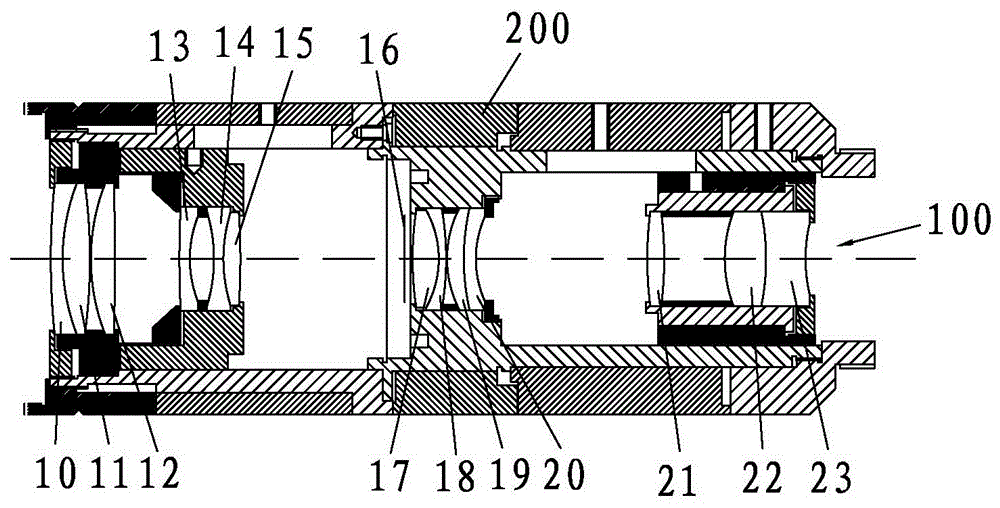

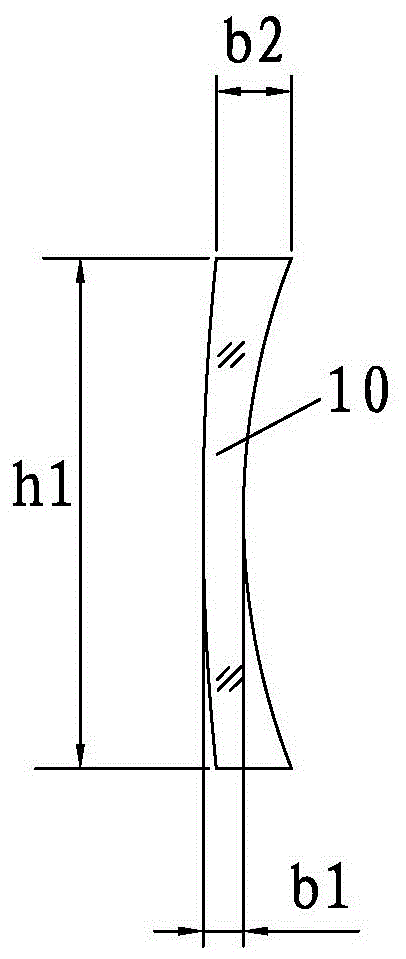

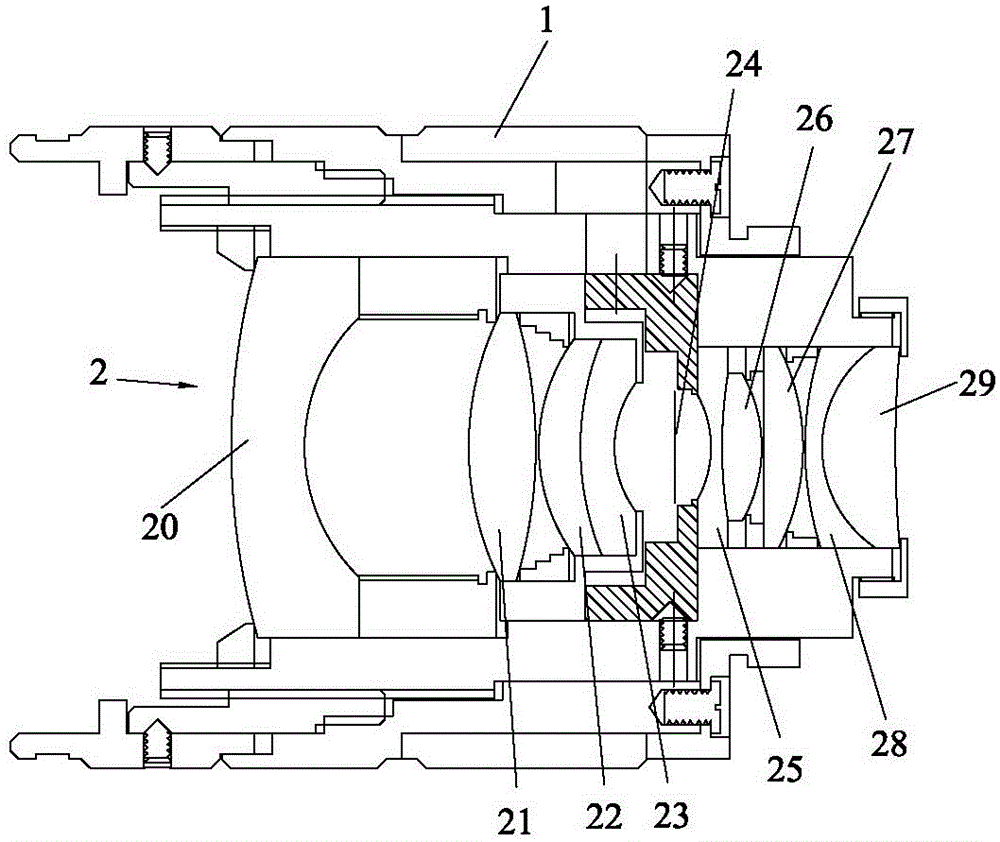

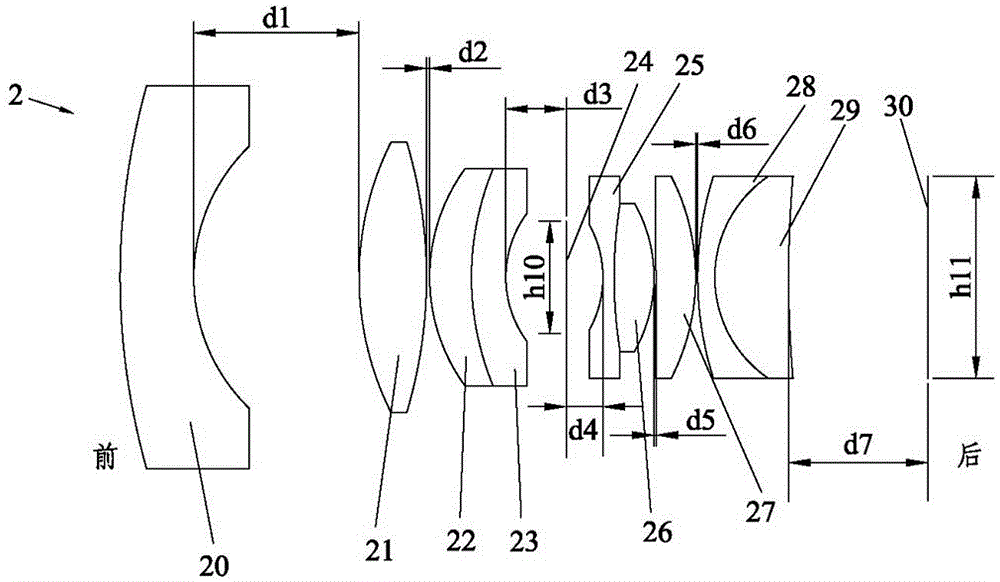

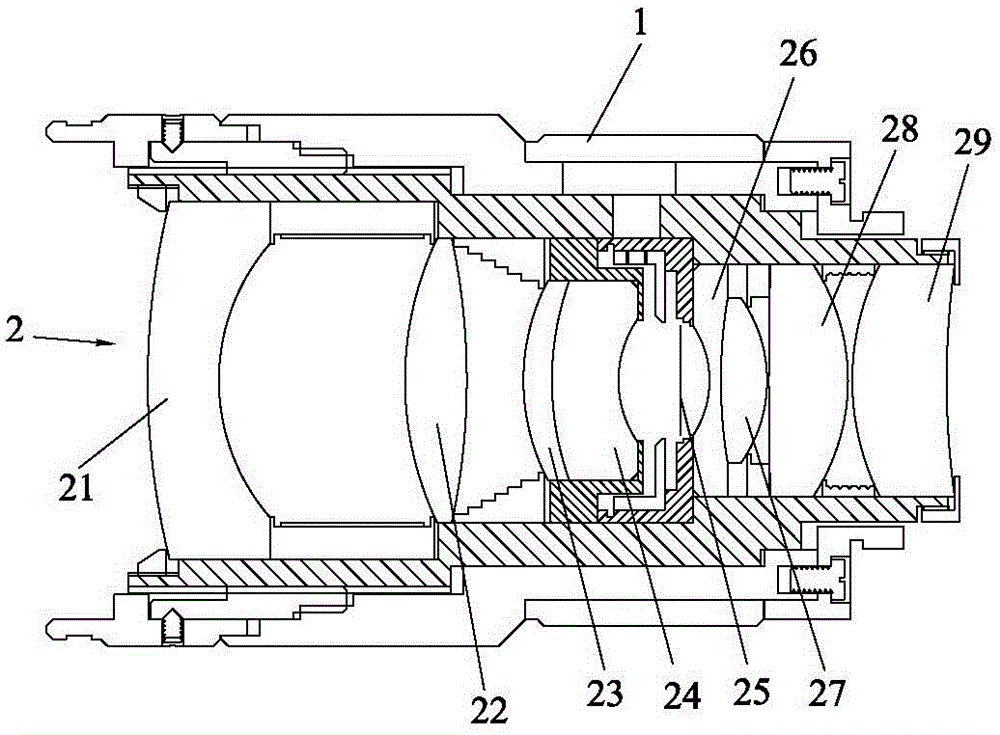

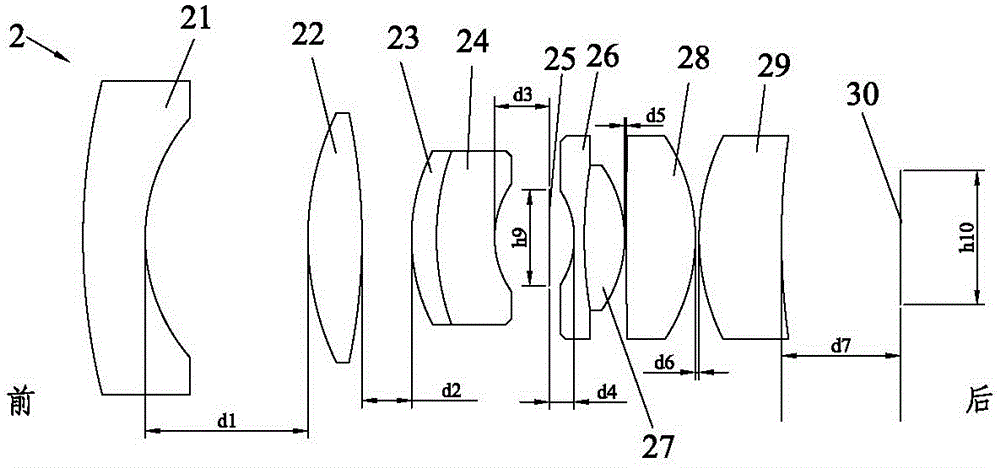

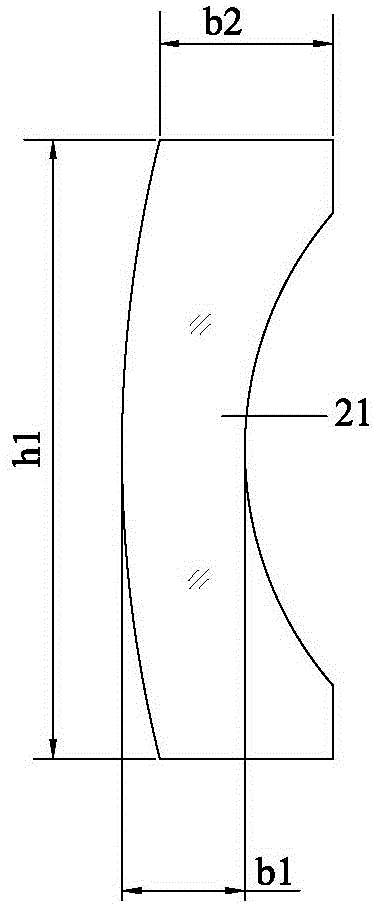

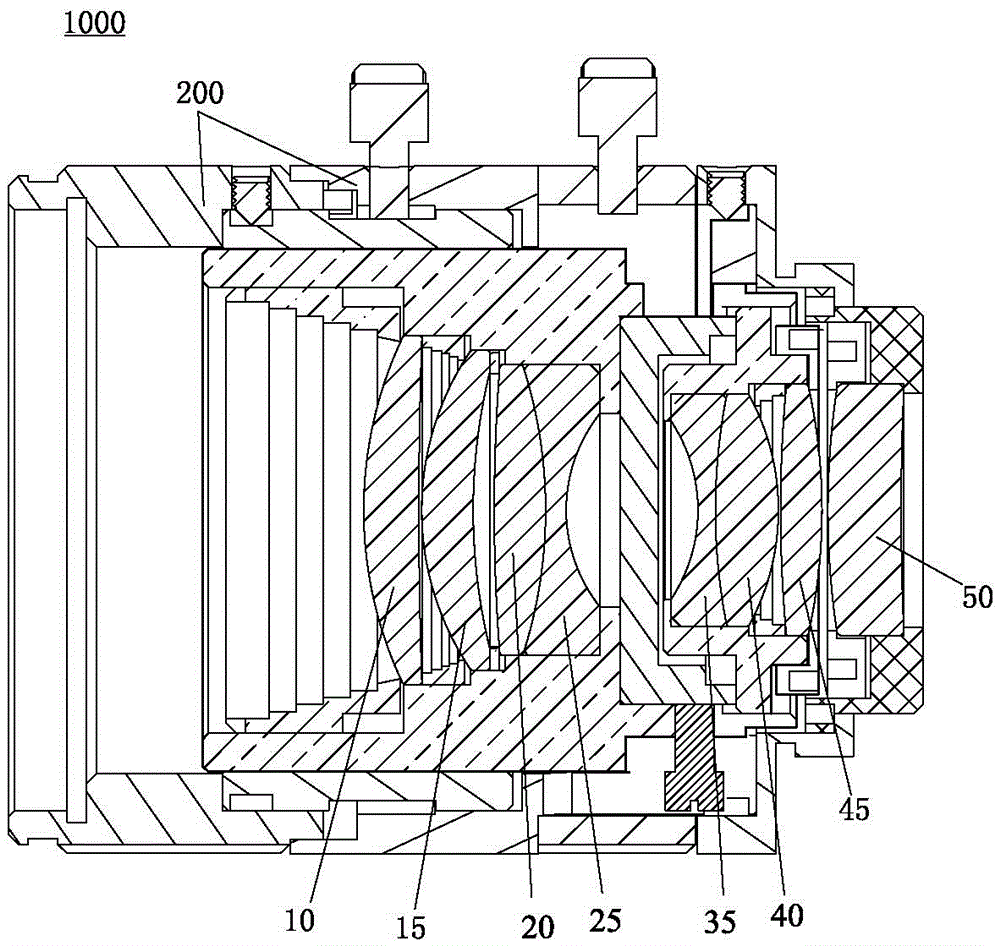

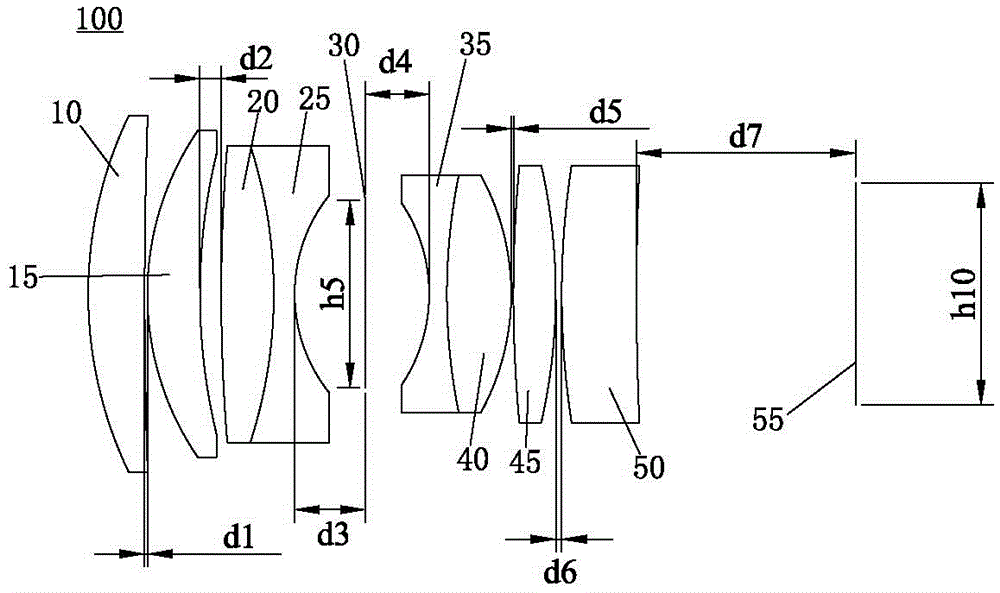

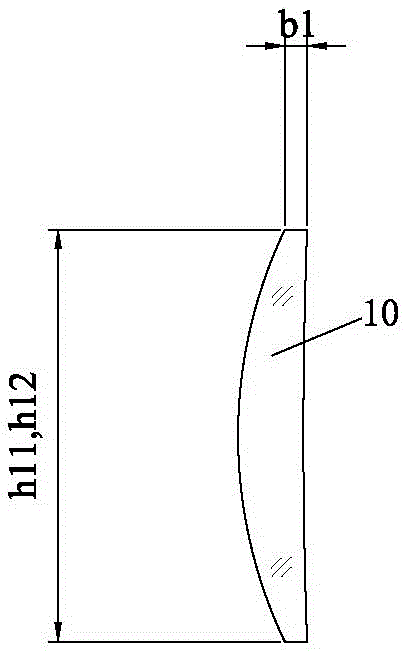

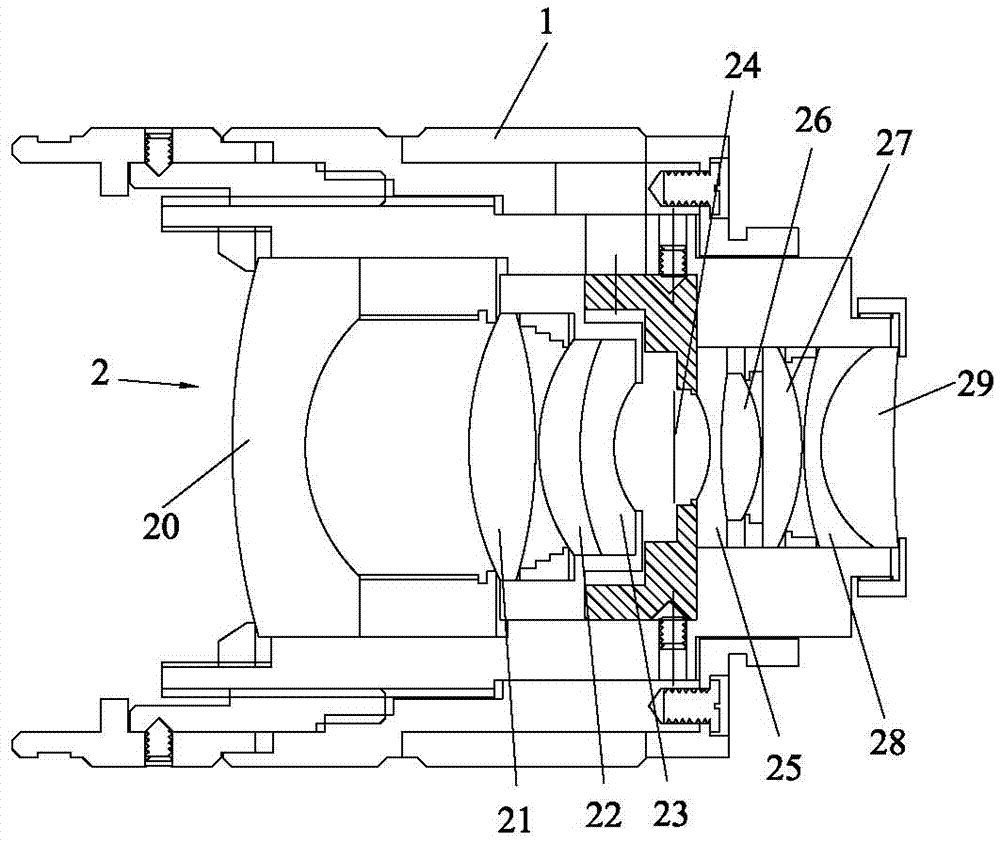

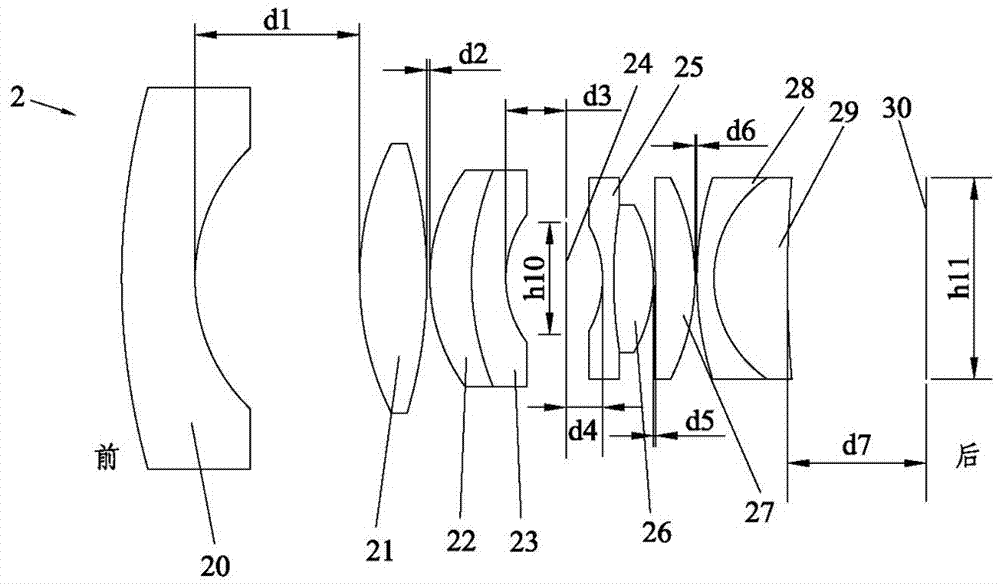

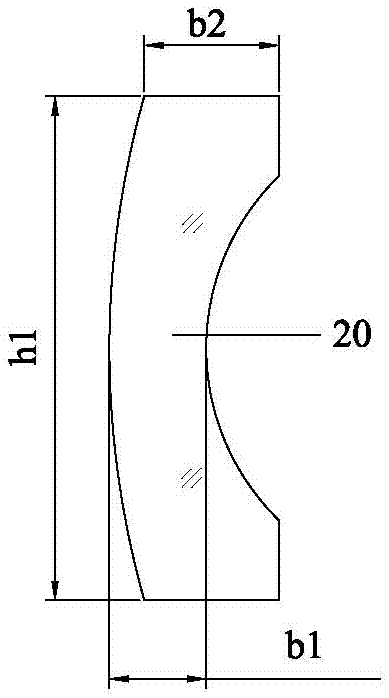

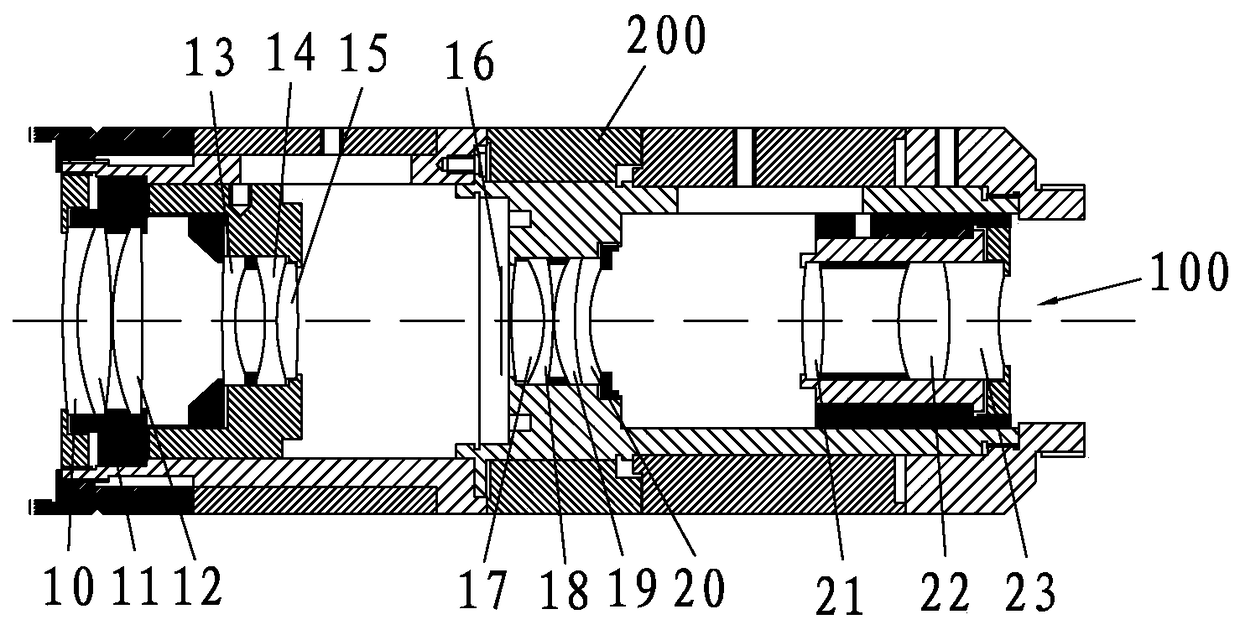

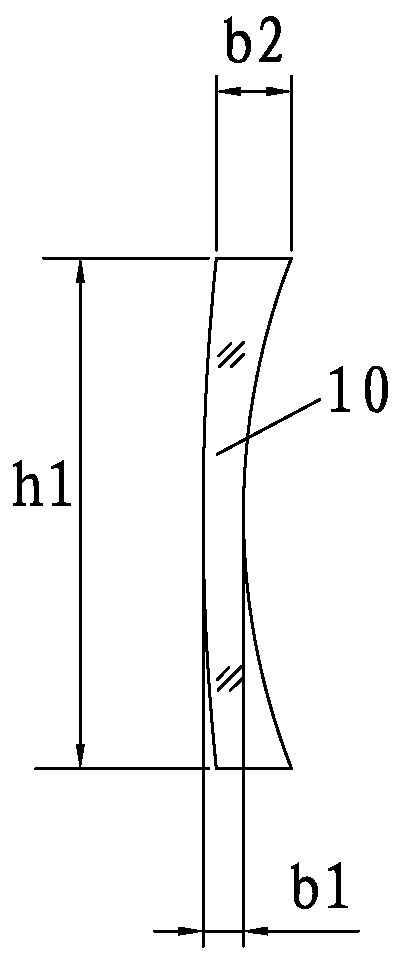

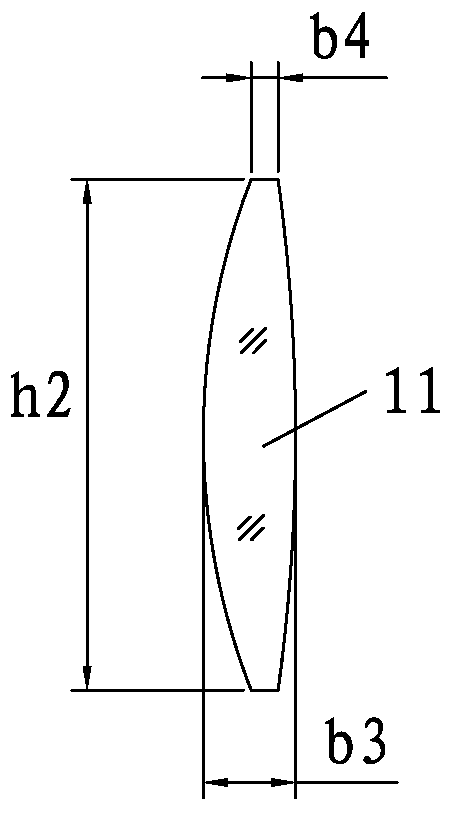

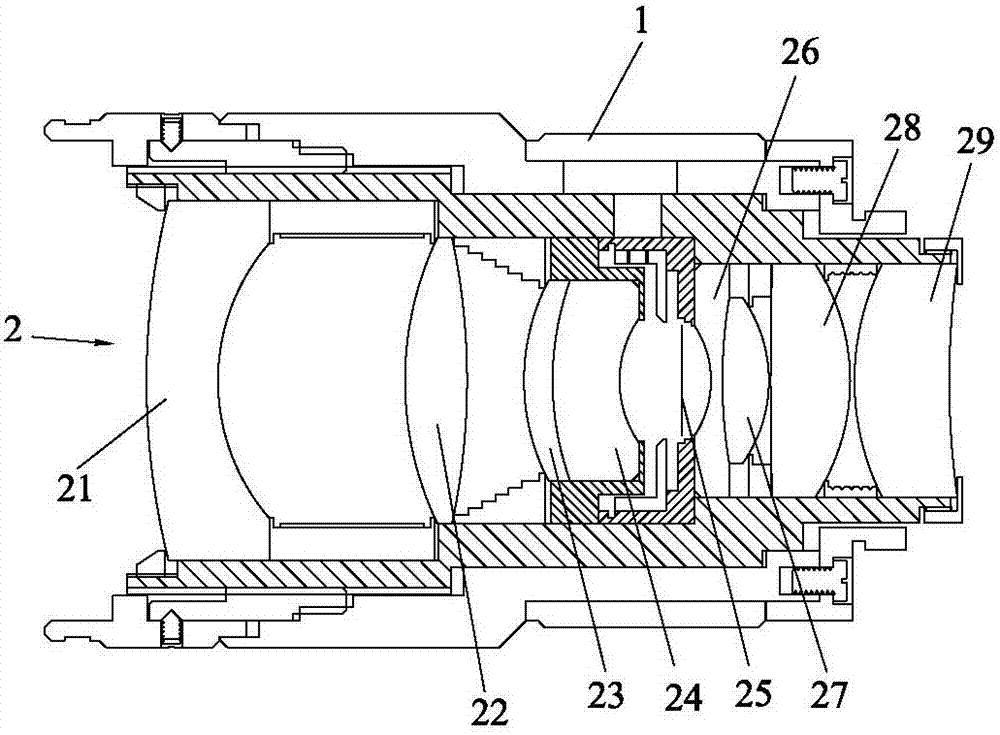

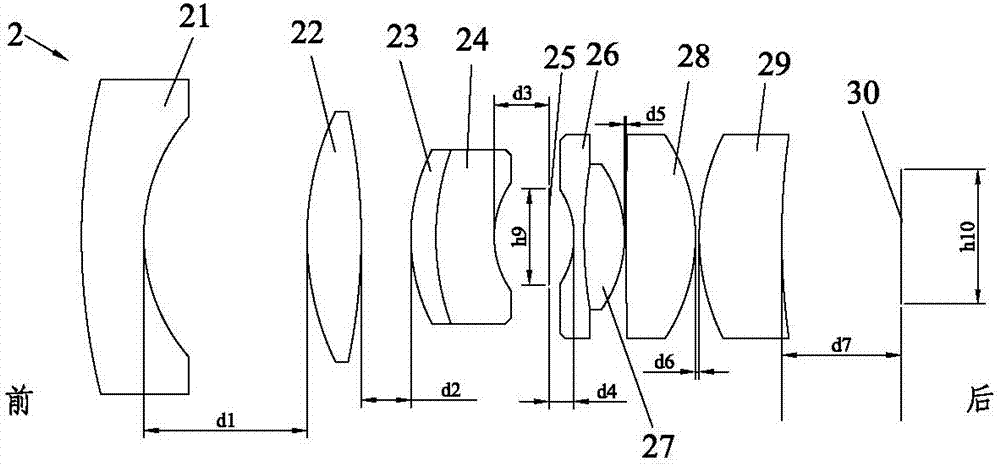

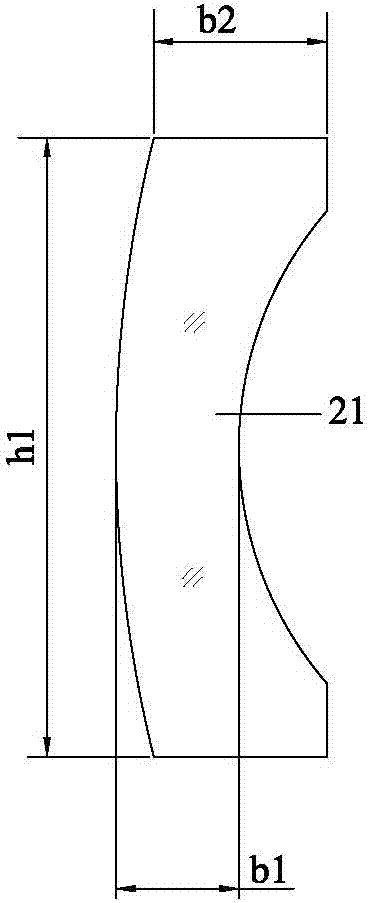

Machine vision camera lens with 8mm fixed focus

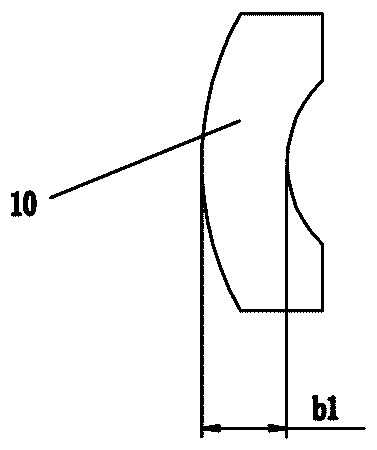

ActiveCN104360460AMeet the needs of high-end productsCompact structureOptical elementsCamera lensConvex structure

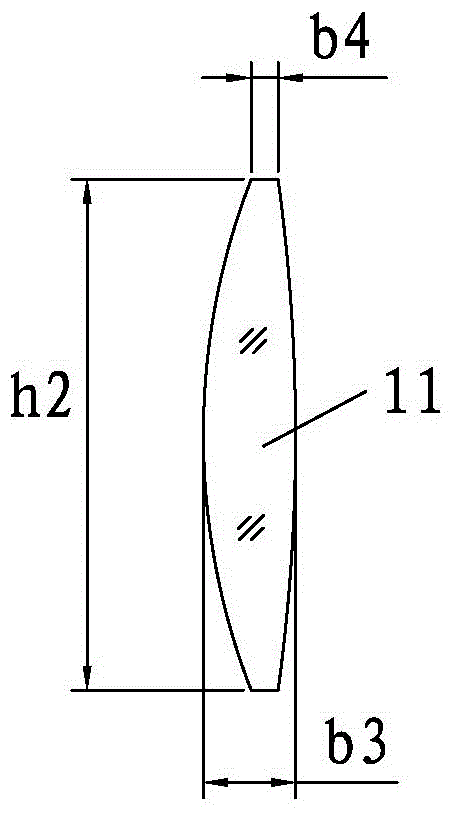

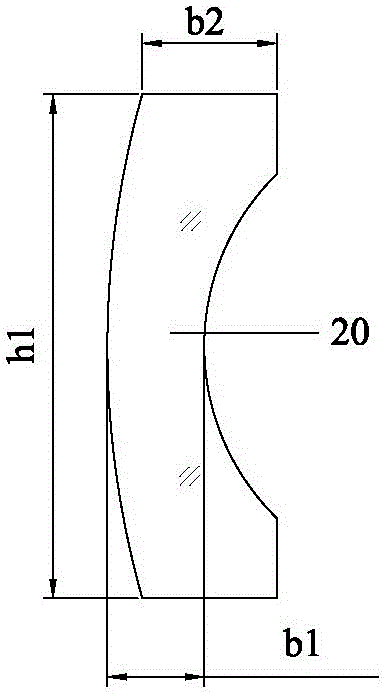

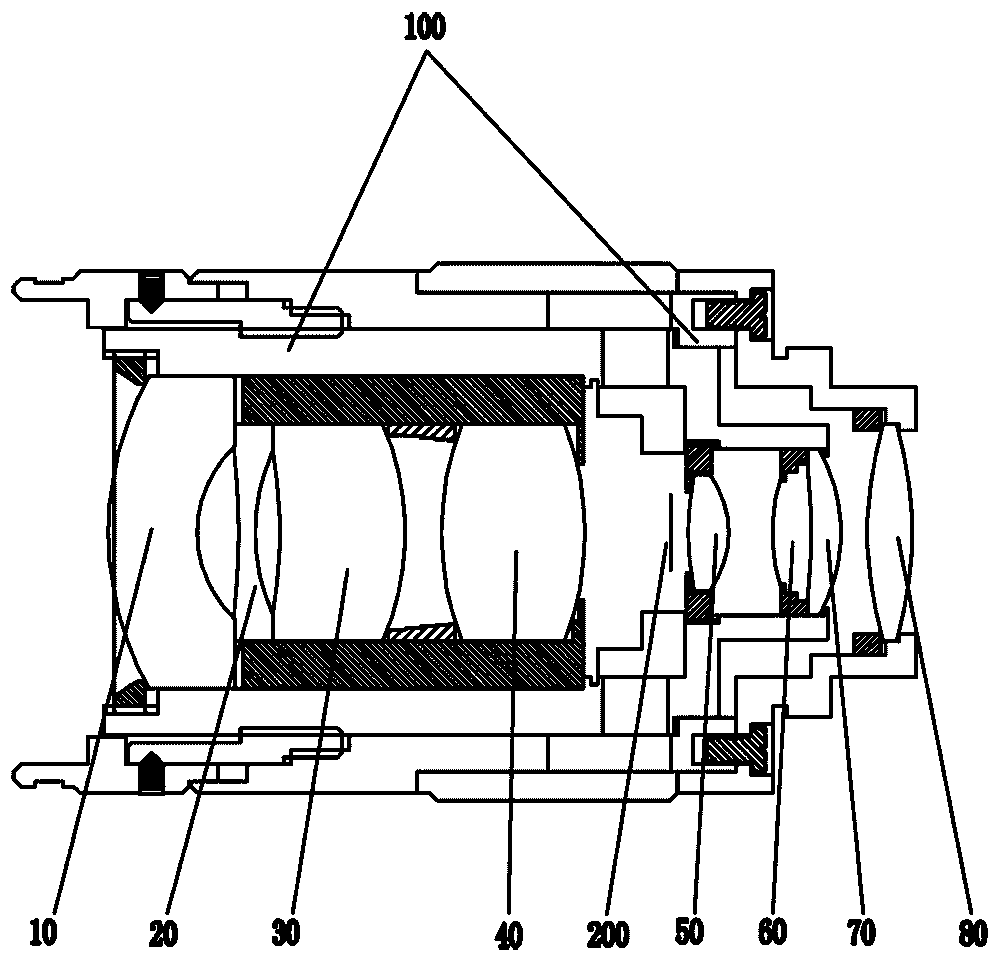

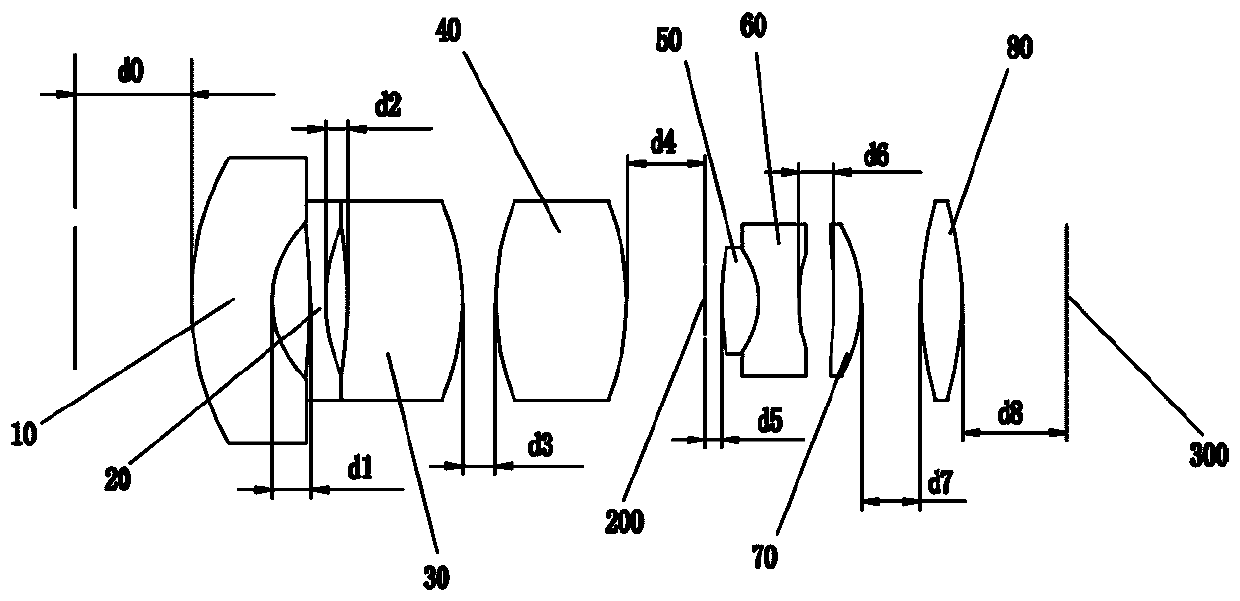

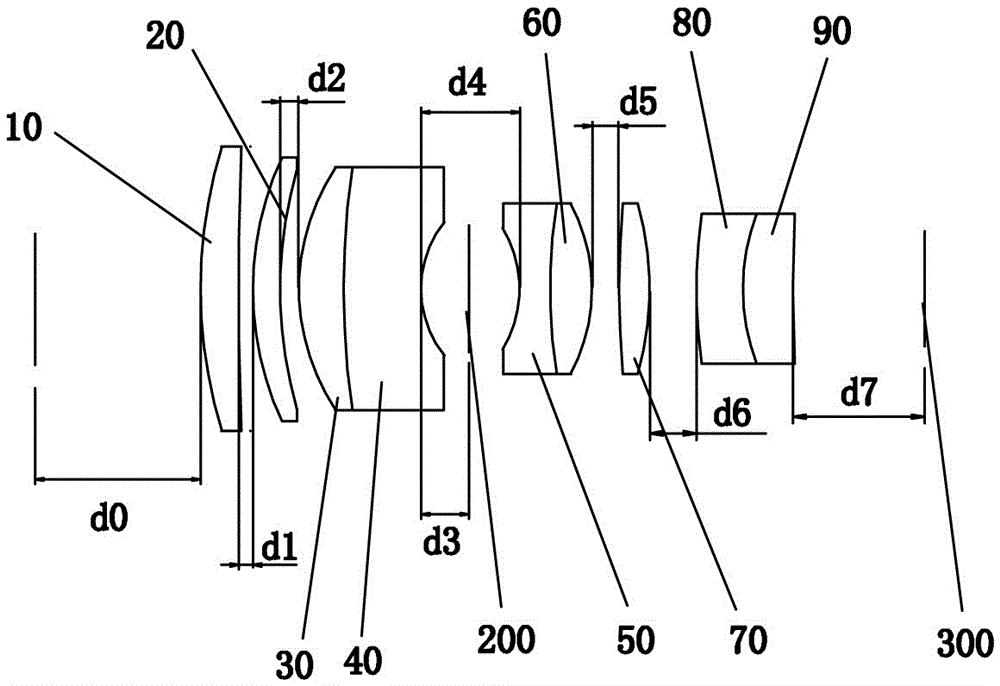

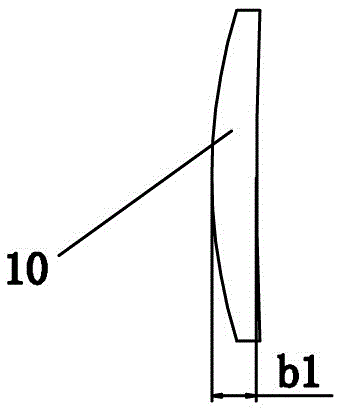

The invention belongs to the technical field of machine vision camera lenses and particularly relates to a machine vision camera lens with an 8mm fixed focus. The machine vision camera lens comprises a first lens with a concave-convex structure, a second lens with a double-concave structure, a third lens with a concave-convex structure, a fourth lens with a double-convex structure, a fifth lens with a double-convex structure, a sixth lens with a double-concave structure, a seventh lens with a concave-convex structure and an eighth lens with a double-convex structure, wherein the first lens, the second lens, the third lens, the fourth lens, the fifth lens, the sixth lens, the seventh lens and the eighth lens are sequentially arranged in a way that the central shafts are coaxial along the light-incident direction; due to the combination of the eight lenses, the pixel value of the camera lens with the 8mm focus can be up to 5 megapixels when the size of a corresponding chip is 2 / 3', so that the high-end product demand is met; and meanwhile, the clear aperture is adjustable within the range of F2.5-F16. The machine vision camera lens with the 8mm fixed focus is compact in structure, convenient to assemble and capable of reducing the production cost.

Owner:GUANGDONG AOPUTE TECH CO LTD

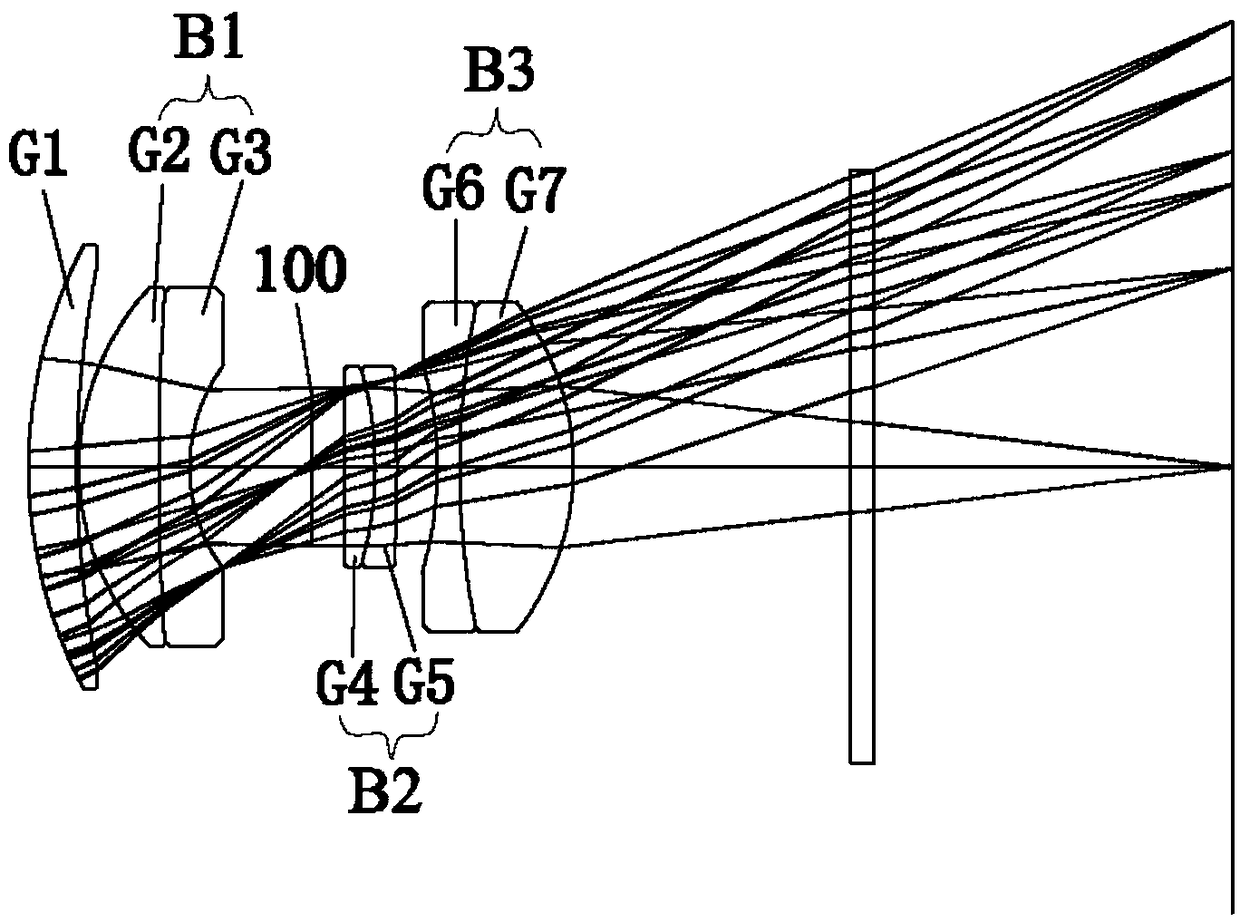

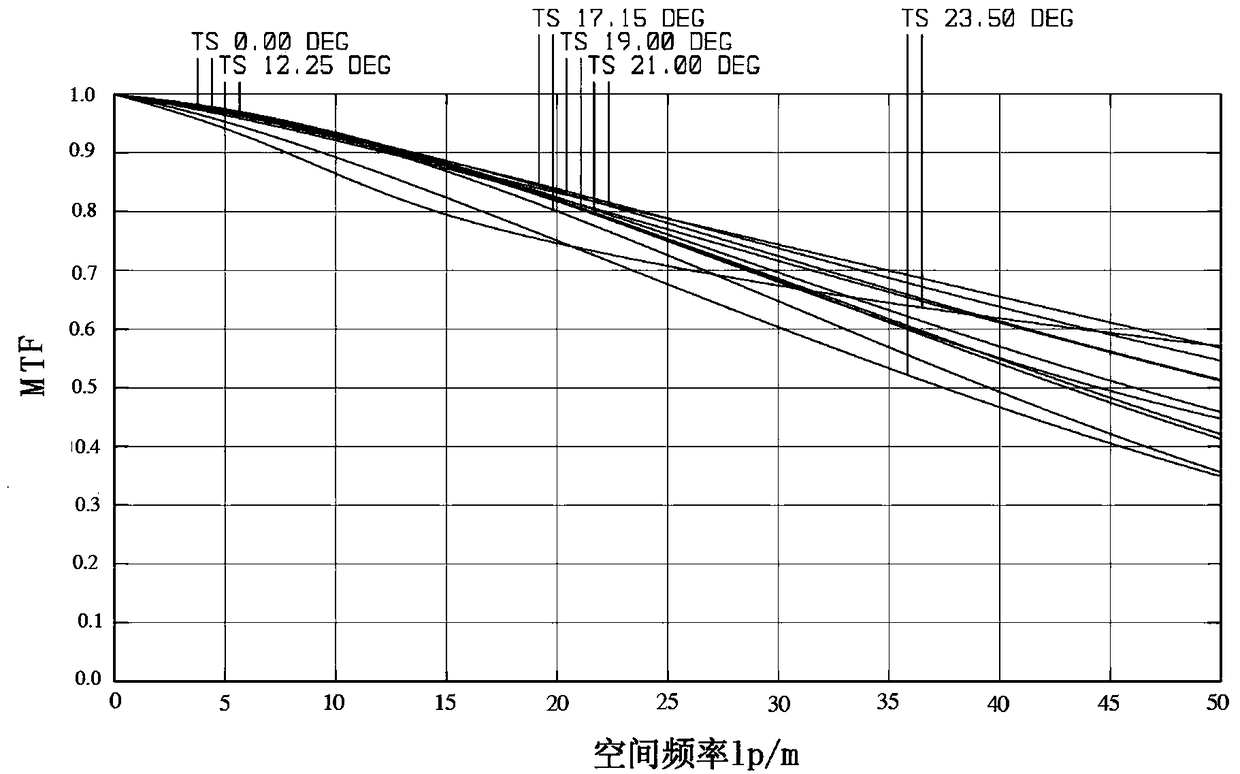

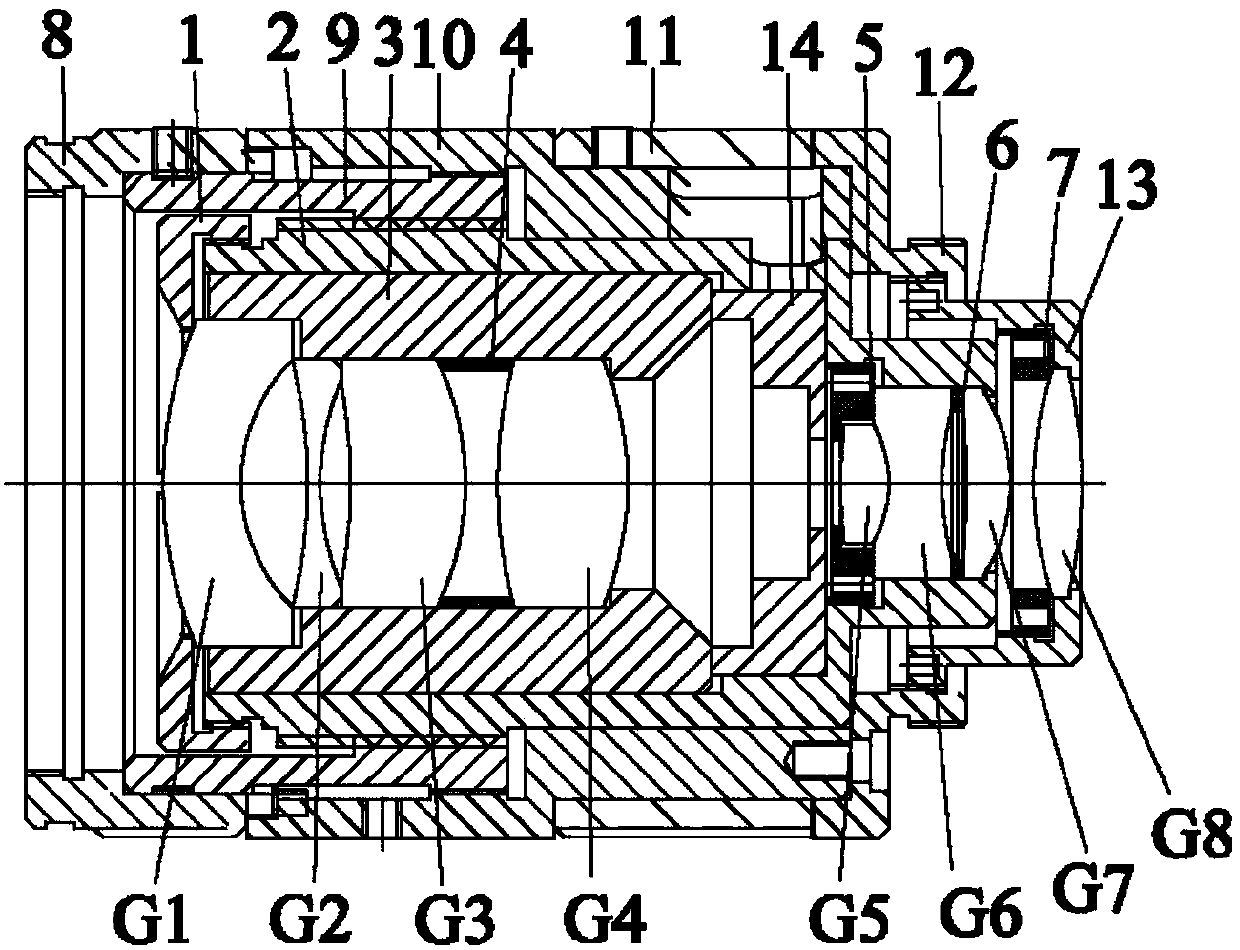

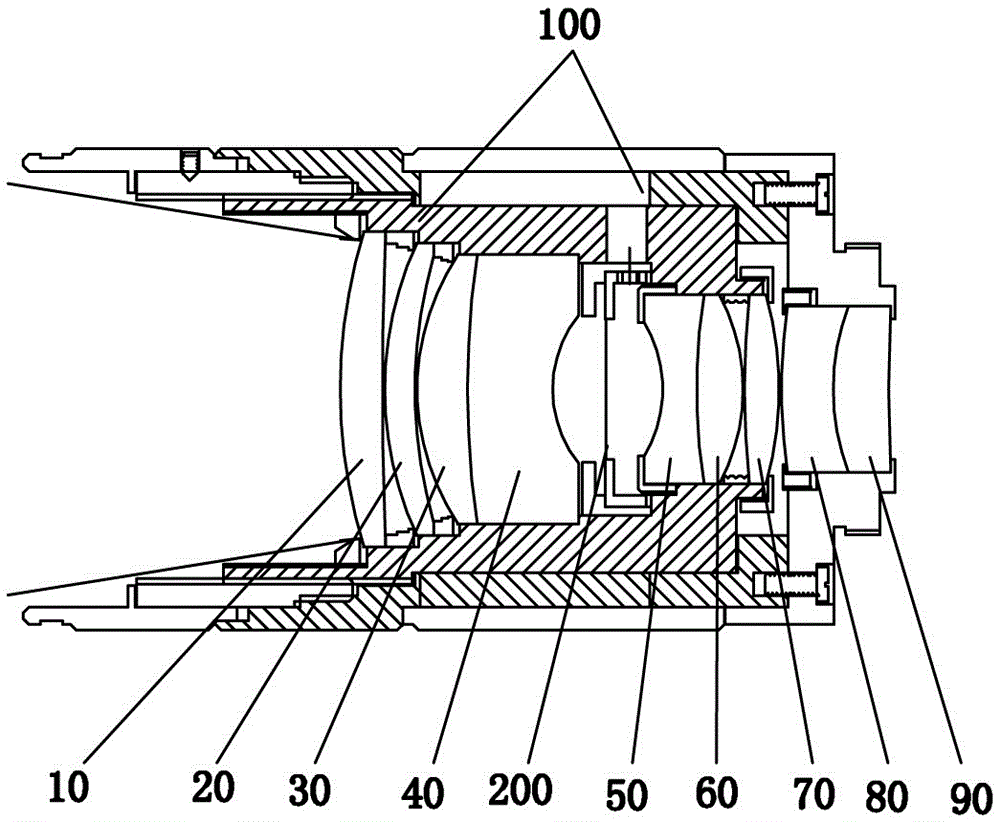

75 mm fixed-focus machine vision lens

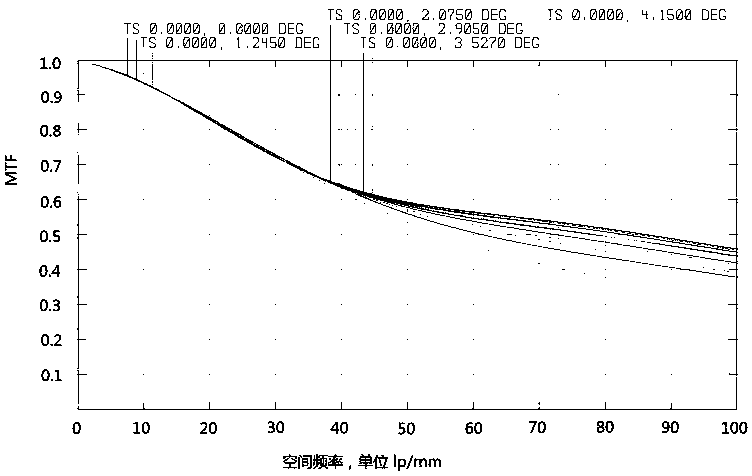

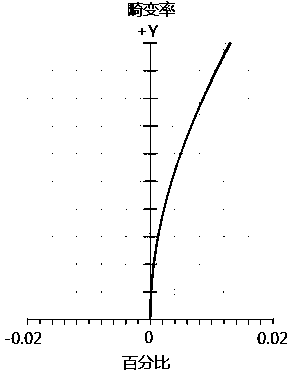

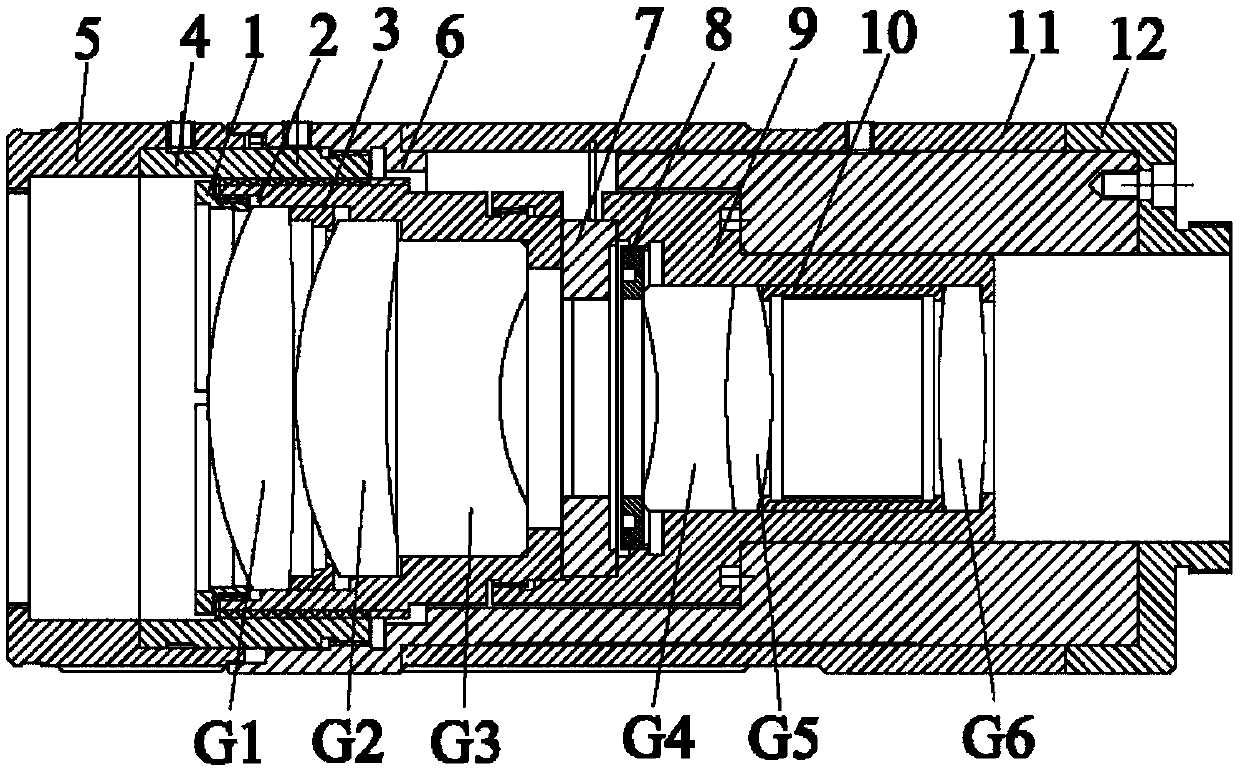

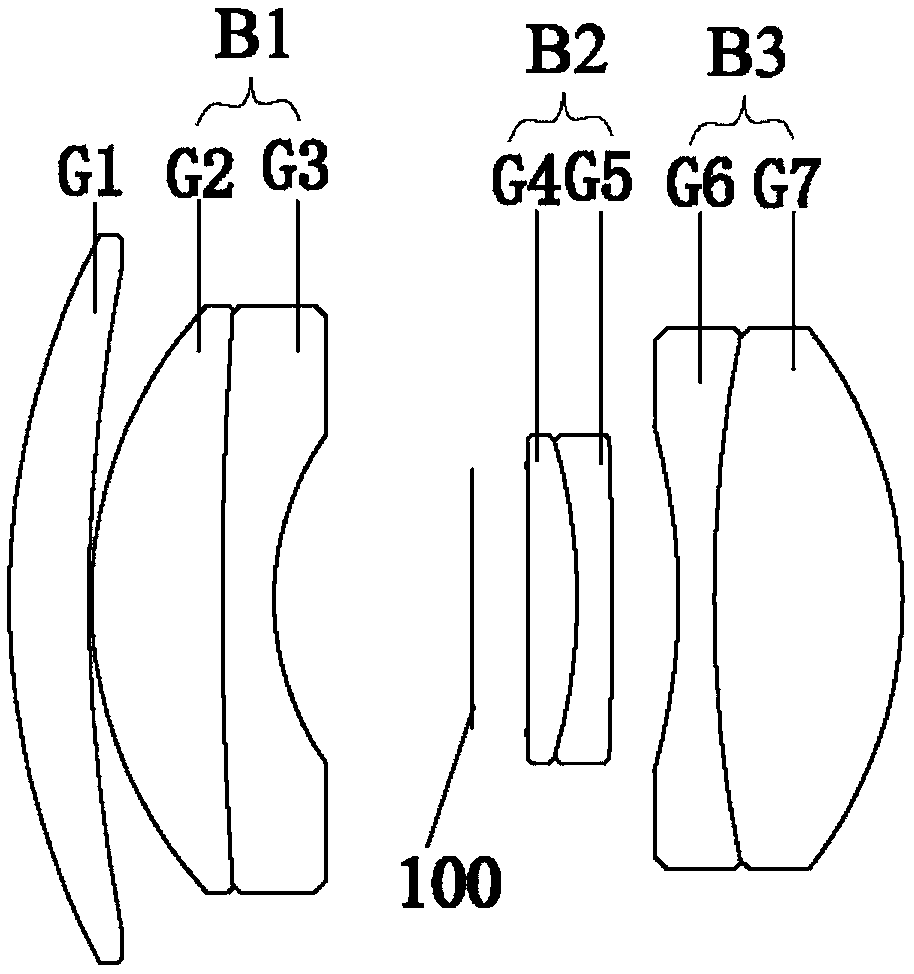

ActiveCN107741626ASmall distortionMeet the needs of high-end productsMountingsMachine visionOphthalmology

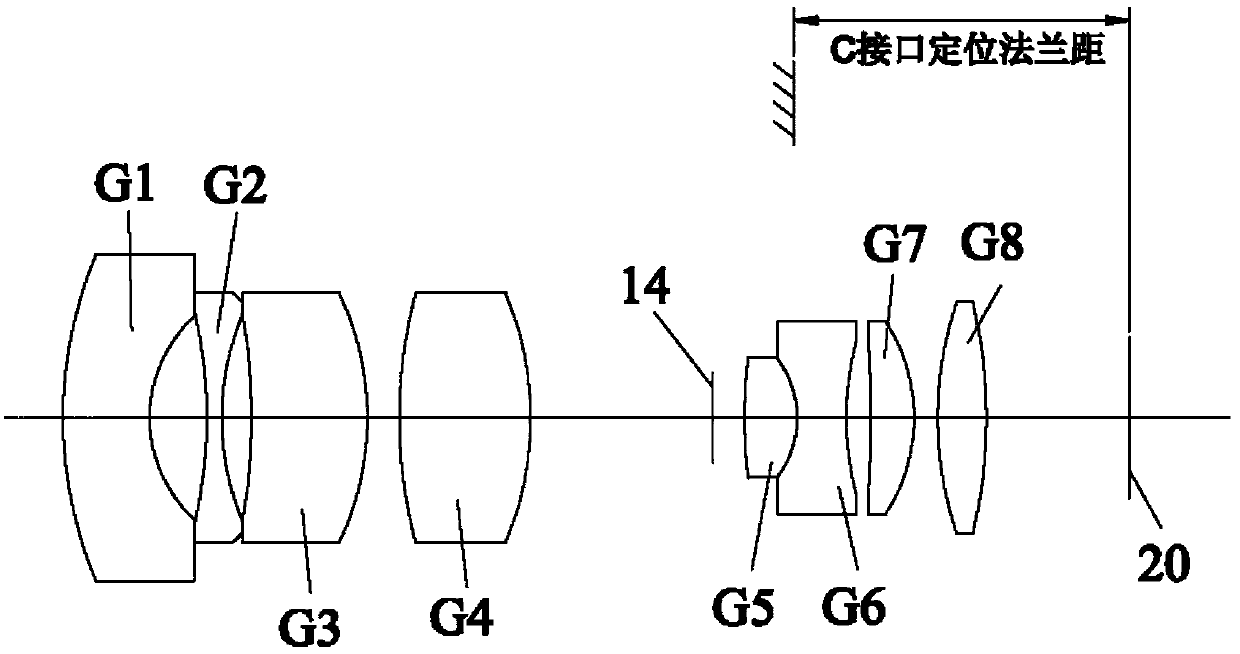

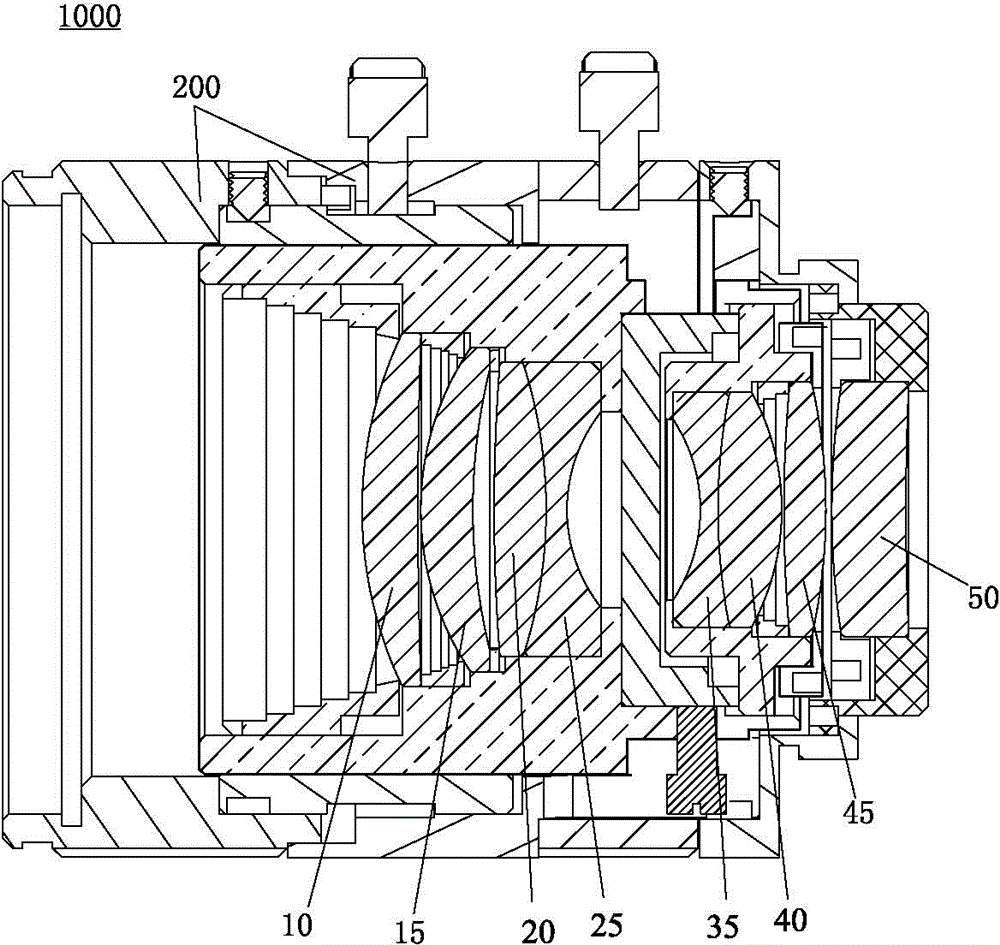

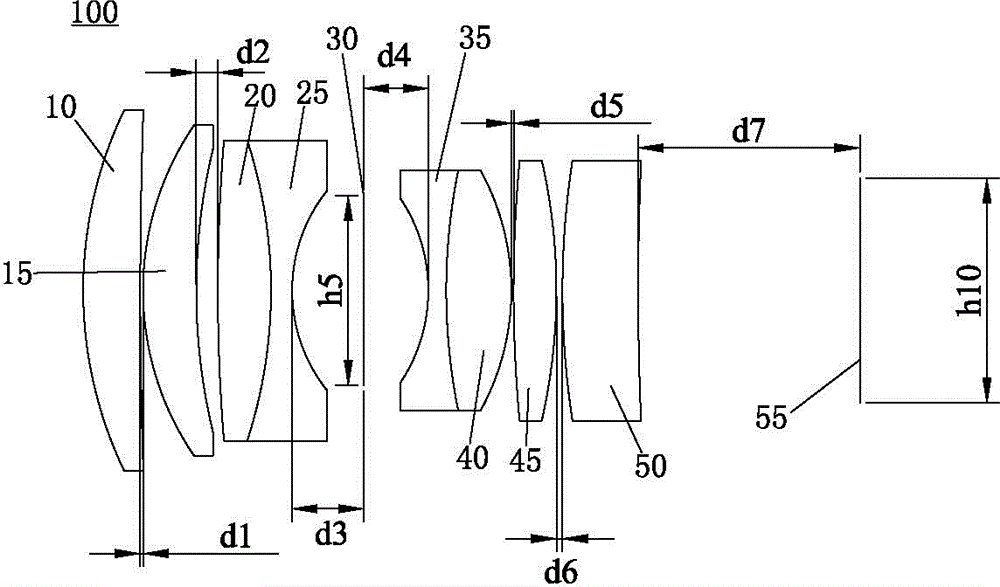

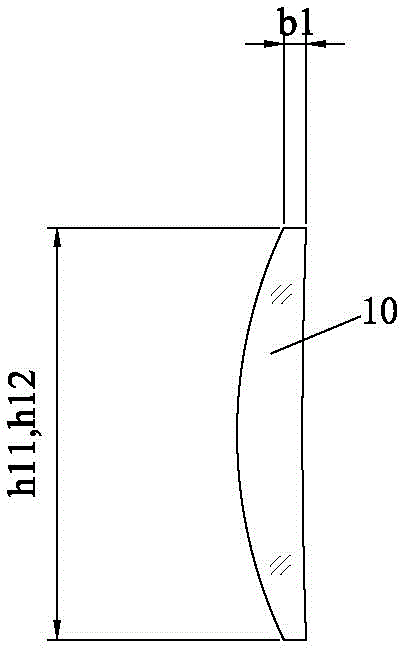

The invention relates to the technical field of machine vision lenses, in particular to a 75 mm fixed-focus machine vision lens. The 75 mm fixed-focus machine vision lens includes a mechanical systemand an optical system which is installed inside the mechanical system; the optical system includes a first lens G1 to an eighth lens G8 in sequence from an object side to an image side, the focal length of the optical system is f, and f, the focal length f1 of the first lens and the focal length f2 of the second lens meet the relation shown in the description; f, the focal length f3 of the third lens and the focal length f4 of the fourth lens meet the relation shown in the description; the focal lens of a balsaming lens B1 is fB1, and fB1 and the focal length f of the optical system meet the relation shown in the description. Through the arrangement of the first lens G1 to the eighth lens G8, the range condition of the focal lengths of the lenses achieves the purpose that when the focal length is 75 mm and the size of a corresponding chip is 2 / 3, the pixel value of the 75 mm fixed-focus machine vision lens can reach 5-megapixel, the distortion rate is smaller than 0.02%, the requirements of high-end products are met, and at the same time, the clear aperture of the 75 mm fixed-focus machine vision lens can also be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

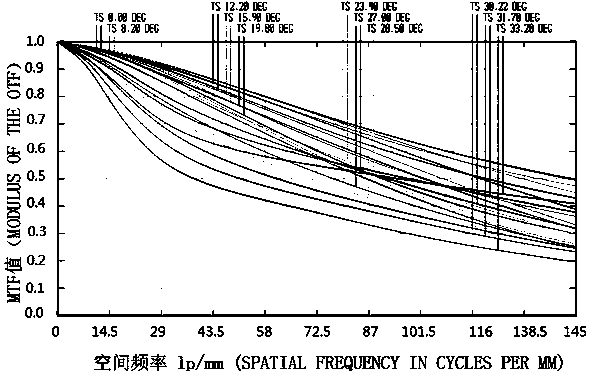

Optical system provided with machine-vision camera lenses with large target areas

PendingCN108710195AHigh quality imagingMeet the needs of high-end productsOptical elementsConvex structureCamera lens

The invention discloses an optical system provided with machine-vision camera lenses with large target areas. The optical system comprises a first lens G1 with positive focal power and a crescent structure, a second lens G2 with positive focal power and a crescent structure, a third lens G3 with negative focal power and a crescent structure, a fourth lens G4 with positive focal power and a double-convex structure, a fifth lens G5 with negative focal power and a crescent structure, a sixth lens G6 with negative focal power and a double-concave structure and a seventh lens G7 with positive focalpower and a double-convex structure from object spaces to image spaces. A relational expression of 0.8 |f1 / f| 1.2 is met by the focal distance f of the optical system and the focal distance f1 of thefirst lens G1, and a relational expression of 2y / f 0.85 is met by a target area 2y of the optical system and the focal distance f. The optical system has the advantages that the optical system can bematched with linear-array cameras with the resolution higher than 8 k and the pixel sizes of 7 micrometers, and accordingly high-quality imaging with the wide working distances of 0.04X-0.33X can beimplemented.

Owner:GUANGDONG AOPUTE TECH CO LTD

6mm fixed-focus machine vision lens

ActiveCN107688225AMeet the needs of high-end productsFlexible adjustment of clear apertureMountingsMachine visionOphthalmology

The invention relates to the technical field of machine vision lenses, in particular to a 6mm fixed-focus machine vision lens. The 6mm fixed-focus machine vision lens comprises a mechanical system andan optical system mounted inside the mechanical system and is characterized in that the optical system sequentially comprises a first lens G1, a second lens G2, a third lens G3, a fourth lens G4, a fifth lens G5, a sixth lens G6, a seventh lens G7 and an eighth lens G8 from the object space to the image space, the focal length of the optical system is f, and f, the focal length f1 of the first lens and the focal length f2 of the second lens satisfy the following relations: 2<|f1 / f|<3, and 1.5<|f2 / f|<2.5; f, the focal length f3 of the third lens and the focal length f4 of the fourth lens satisfy the following relations: 4<|f3 / f|<5.5, and 2<|f4 / f|<3.5; the focal length of a first bonding lens B1 is fB1, and fB1 and f satisfy the following relation: 1.5<fB1 / f|<3. By the arrangement of the first lens G1, the second lens G2, the third lens G3, the fourth lens G4, the fifth lens G5, the sixth lens G6, the seventh lens G7 and the eighth lens G8, and the range conditions of the focal lengthsof the lenses, the pixel value of the 6mm fixed-focus machine vision lens can reach 2.5 megapixels when the focal length is 6mm and the size of a corresponding chip is 1 / 2', high-end product requirements are satisfied, and the clear aperture of the 6mm fixed-focus machine vision lens can be adjusted flexibly.

Owner:GUANGDONG AOPUTE TECH CO LTD

Lens combined structure and machine visual lens with lens combined structure

ActiveCN104360461AMeet the needs of high-end productsFlexible adjustment of clear apertureOptical elementsCamera lensMachine vision

The invention relates to the technical field of optical lenses and particularly relates to a lens combined structure. The lens combined structure comprises a first lens, a second lens, a third lens, a fourth lens, a diaphragm, a fifth lens, a sixth lens, a seventh lens and an eighth lens, center axes of which are positioned on the horizontal line, wherein the distance between the top of the front end surface of the eighth lens and the top of the rear end surface of the seventh lens is regulated between 0.1mm and 6mm. When the focal length is 25mm by virtue of the lens combined structure, the dimension of the corresponding chip is 2 / 3'', the pixel value of the lens combined structure can reach 5 millions of pixels, so that the high-end product needs are met, and the clear aperture of the lens combined structure can be flexibly regulated. Besides, the invention further discloses a machine visual lens with the lens combined structure.

Owner:GUANGDONG AOPUTE TECH CO LTD

Preparation method of titanium dioxide with high specific surface area

Owner:仙桃市中星电子材料有限公司

3X zoom machine vision lens

ActiveCN106094181AMeet the needs of high-end productsFlexible adjustment of clear apertureOptical elementsMachine visionComputer science

The invention discloses a 3X zoom machine vision lens. The 3X zoom machine vision lens comprises a lens combination structure; the lens combination structure includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a diaphragm, a seventh lens, an eighth lens, a ninth lens, a tenth lens, an eleventh lens, a twelfth lens and a thirteenth lens; the axes of the first lens, the second lens, the third lens, the fourth lens, the fifth lens, the sixth lens, the diaphragm, the seventh lens, the eighth lens, the ninth lens, the tenth lens, the eleventh lens, the twelfth lens and the thirteenth lens are located on the same horizontal line; the first lens, the second lens and the third lens constitute a first lens group; the fourth lens, the fifth lens and the sixth lens constitute a second lens group; the seventh lens, the eighth lens, the ninth lens and the tenth lens constitute a third lens group; and the eleventh lens, the twelfth lens and the thirteenth lens constitute a fourth group. According to the 3X zoom machine vision lens of the invention, the first lens group, the second lens group, the third lens group and the fourth group cooperate with one another, so that the pixel value of the 3X zoom machine vision lens can achieve 5 million pixels when a working distance is 90mm, and the size of a corresponding chip is 2 / 3, and therefore, the requirements of high-end products can be satisfied; and the light passing aperture of the 3X zoom machine vision lens can be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

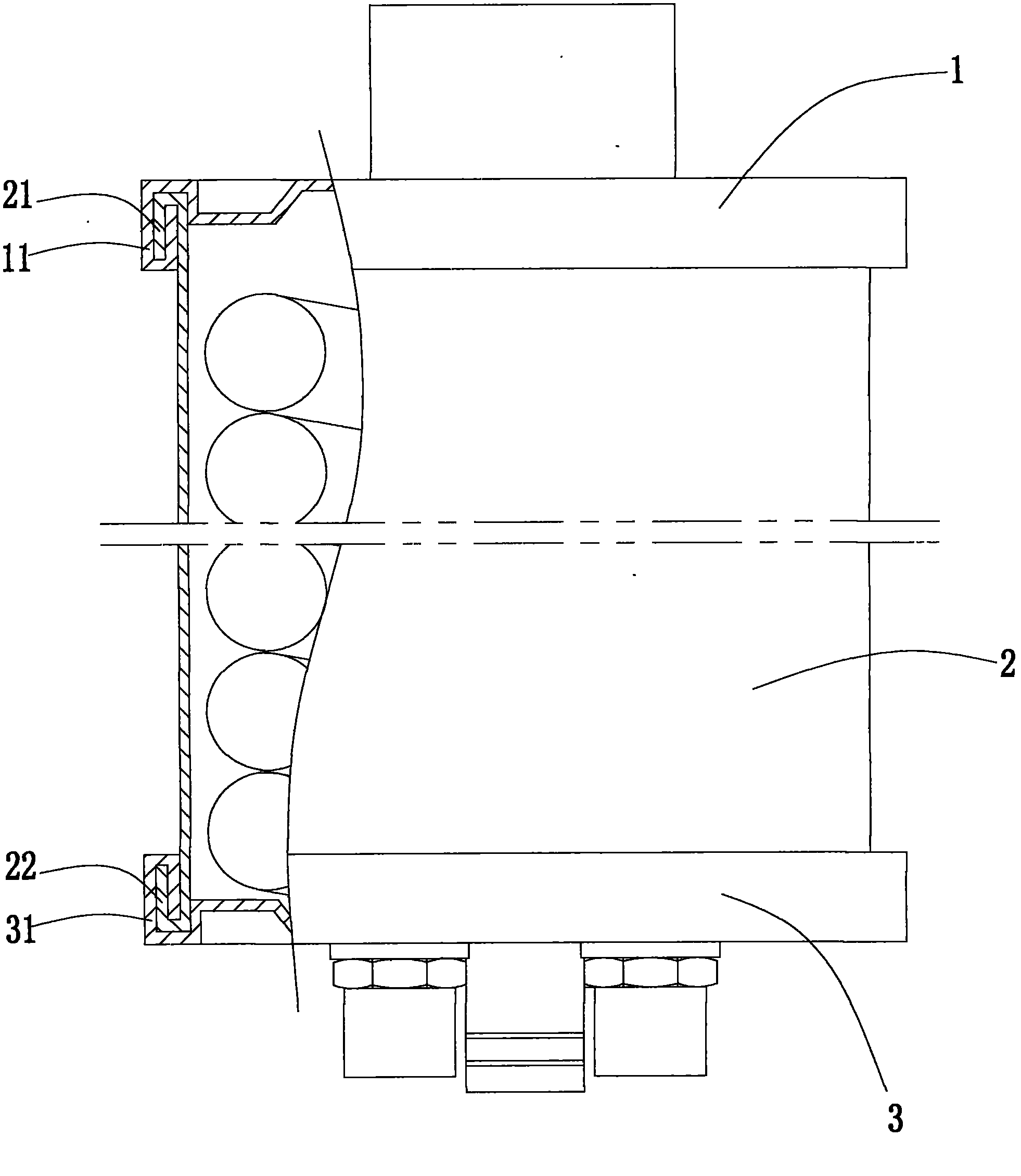

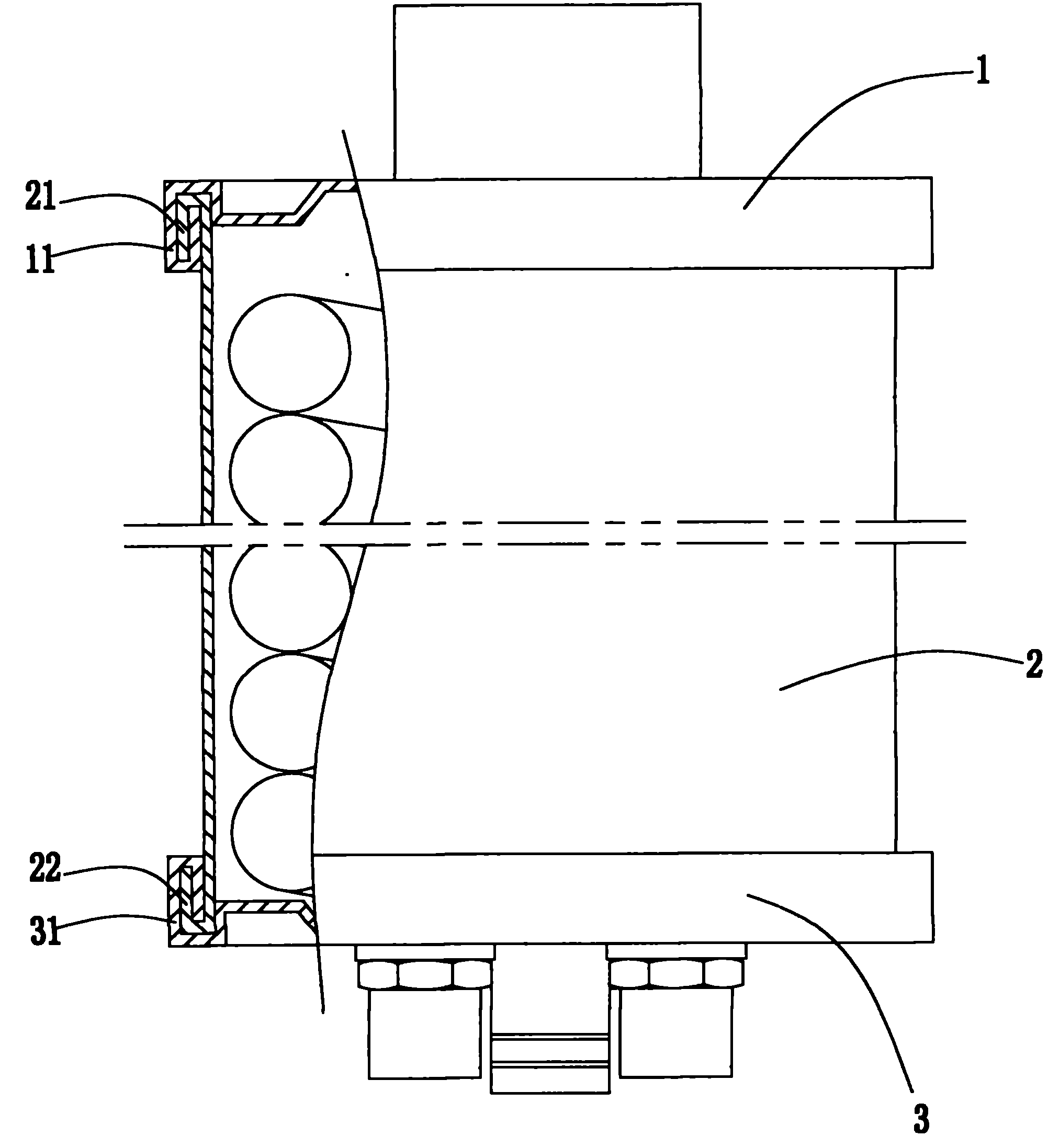

Condensation cavity for gas water heater and manufacturing technology thereof

InactiveCN102635947AEasy to operateIncrease productivityFluid heatersHollow articlesRubber ringEnvironmental resistance

The invention relates to a condensation cavity for a gas water heater, wherein the condensation cavity for the gas water heater comprises an upper cover, a cylinder body and a lower cover, wherein the upper cover is provided with a first folding edge; the cylinder body is provided with a second folding edge and a third folding edge; the lower cover is provided with a fourth folding edge; the first folding edge of the upper cover and the second folding edge of the cylinder body are tightly jointed together in a compression mode through a roller press; and the fourth folding edge of the lower cover and the third folding edge of the cylinder body are tightly jointed together in a compression mode through the roller press. Compared with the prior art, the condensation cavity for the gas water heater provided by the invention has the following beneficial effects: 1) the roller press is utilized for compression joint production, the production efficiency is improved by 4-5 times, and the single-batch output production capability can reach more than 600 units; 2) high-temperature silicon gel is not required for sealing, the condensation cavity for the gas water heater not only is environmentally-friendly, but also is clean, and has no foreign smell and pollution, the technology is simple, and the operation for workers is easy; 3) a rubber ring and high-temperature silicon gel are omitted, and hazards of aging, leakage, bursting and the like do not exist; 4) the product cost is lowered, and the product competitiveness is improved; and 5) the product appearance is improved greatly, and the requirements of higher-level products can be met. The invention also relates to a manufacturing technology of the condensation cavity for the gas water heater.

Owner:林慧贤

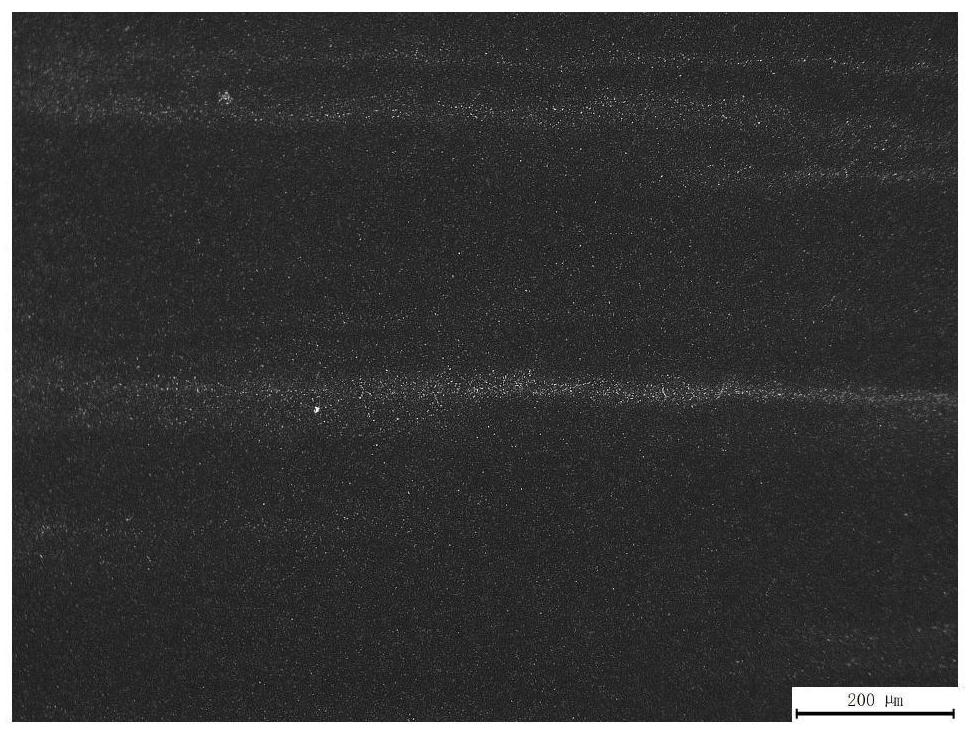

Method for controlling carbide banded structure of high-carbon chromium bearing steel

PendingCN114101615AImprovement ingredientsGood composition uniformityRoll force/gap control deviceMetal rolling arrangementsTemperature controlCarbide

The invention discloses a control method for a high-carbon-chromium bearing steel carbide banded structure, and belongs to the field of bearing steel preparation. The method specifically comprises the following steps: obtaining a casting blank by adopting a crystallizer electromagnetic stirring and tail-section soft reduction process; the casting blank is placed in a heating furnace to be subjected to primary high-temperature diffusion; the casting blank is subjected to cogging rolling, a rolled intermediate blank is subjected to secondary high-temperature diffusion, during cogging rolling of the casting blank, the cogging process of the casting blank is controlled to be seven passes, the first three passes adopt a large reduction process, the reduction rate of the first pass is controlled to be 28-30%, the reduction rate of the second pass is controlled to be 22-24%, and the reduction rate of the third pass is controlled to be 26-28%; then the rolled intermediate billet is put into a heating furnace for secondary high-temperature diffusion; the heating temperature of the secondary high-temperature section is controlled to be 1170-1230 DEG C, the total heating time is controlled to be 200-280 min, and the time of the high-temperature section is 110-190 min; and then a continuous rolling mill is adopted for rolling, and the bearing steel with the carbide banded grade CZ7 smaller than or equal to 7.3 grade is obtained.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

12mm prime machine visual lens

ActiveCN105044882AMeet the needs of high-end productsAchieve focal lengthOptical elementsPhysicsCamera lens

The invention relates to the technical field of optical lenses, and particularly relates to a 12mm prime machine visual lens comprising a first lens, a second lens, a third lens, a fourth lens, a diaphragm, a fifth lens, a sixth lens, a seventh lens, an eighth lens and a ninth lens of which the central axes are arranged on the same horizontal line. When object distance changes, air space from the ninth lens to an image plane changes, i.e. the first to the ninth lenses move forward and backward together, only optical back focal length changes and other space size does not change. With application of the aforementioned structure, the pixel value can reach five million pixels when the focal length is 12mm and the corresponding chip size is 2 / 3" so that the high-end product demand can be met, and optical transmission aperture can also be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

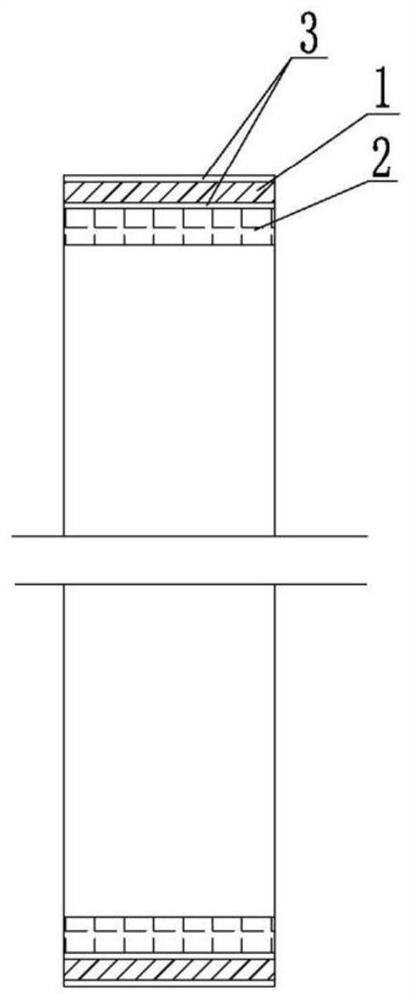

Reinforcing ring structure, preparation process and application thereof

PendingCN113178972AImprove rigidityHigh strengthWindings insulation shape/form/constructionPolyurea/polyurethane coatingsHeat resistanceEngineering

The invention discloses a reinforcing ring structure, and a preparation process and application thereof, and belongs to the technical field of reinforcing ring structures. The reinforcing ring structure sleeves the two ends of an armature coil and comprises a rigid layer and an insulating layer, a phosphating and saponifying layer is arranged outside the rigid layer, the insulating layer is coated at the inner side of the phosphating and saponifying layer, and the insulating layer and the outer insulating paint of the armature coil are mutually permeated and fused. The reinforcing ring structure has the advantages that the reinforcing ring structure has certain strength, meanwhile, the portion, making contact with the armature coil, of the reinforcing ring structure has insulativity and good heat resistance, the fusion degree of the reinforcing ring structure and insulating paint outside the armature coil is high, the reliability and working stability of a starter rotor are improved, and the service life of the starter rotor is prolonged.

Owner:芜湖兴申汽车部件有限公司

8mm fixed focus machine vision lens

ActiveCN104360460BMeet the needs of high-end productsCompact structureOptical elementsConvex structureCamera lens

Owner:GUANGDONG AOPUTE TECH CO LTD

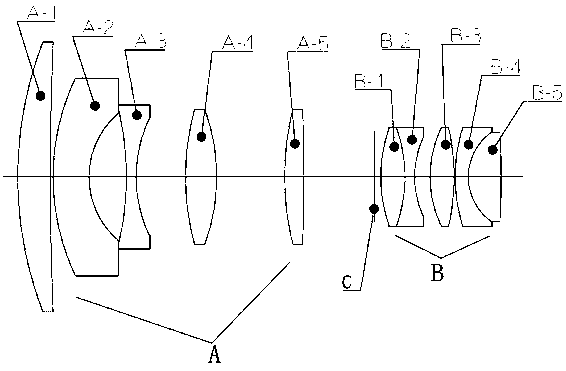

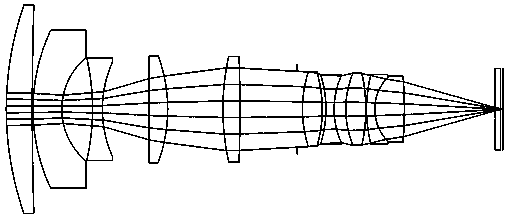

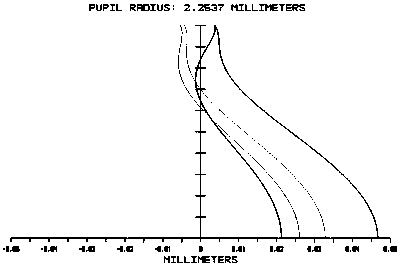

Machine vision lens and imaging method with large field of view and large aperture

The invention relates to a machine vision lens with the large visual field and the large aperture and an imaging method. The machine vision lens comprises an optical system arranged in a lens cone. The optical system comprises a front set A with the positive focal power, a variable diaphragm C and a back set B with the positive focal power, wherein the front set A with the positive focal power, the variable diaphragm C and the back set B with the positive focal power are sequentially arranged in the light incident direction. The front set A comprises a positive meniscus lens A-1, a negative meniscus lens A-2, a biconcave lens A-3, a lens A-4 and a biconvex lens A-5, wherein the positive meniscus lens A-1, the negative meniscus lens A-2, the biconcave lens A-3, the lens A-4 and the biconvex lens A-5 are sequentially arranged. The back set B is a gluing set, and comprises a biconvex lens B-1, a biconcave lens B-2, a biconvex lens B-3, a negative meniscus lens B-4 and a biconvex lens B-5, wherein the biconvex lens B-1, the biconcave lens B-2, the biconvex lens B-3, the negative meniscus lens B-4 and the biconvex lens B-5 are sequentially arranged and closely connected. The machine vision lens has the advantages of being large in visual field angle, low in distortion, large in relative aperture, high in resolution and short in total optical length, and the requirement of a high-end product is met.

Owner:FUJIAN NORMAL UNIV

16mm prime machine visual lens

ActiveCN105044883AAchieve focal lengthMeet the needs of high-end productsOptical elementsPhysicsProduct demand

The invention relates to the technical field of optical lenses, and particularly relates to a 16mm prime machine visual lens comprising a first lens, a second lens, a third lens, a fourth lens, a diaphragm, a fifth lens, a sixth lens, a seventh lens and an eighth lens of which the central axes are arranged on the same horizontal line. When object distance changes, air space from the eighth lens to an image plane changes, i.e. the first to the eighth lenses move forward and backward together, only optical back focal length changes and other space size does not change. With application of the aforementioned structure, the pixel value can reach five million pixels when the focal length is 16mm and the corresponding chip size is 2 / 3" so that the high-end product demand can be met, and optical transmission aperture can also be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

Egg white powder with high foamability and preparation method thereof

The invention provides egg white powder with high foamability and a preparation method thereof and relates to reconstruction of whey protein structure and functional properties, belonging to the technical field of biological processing of foodstuffs. According to the invention, on the basis of preliminary work, enzymatic hydrolysis of lipase in advance and cooperative enzymatic hydrolysis of composite protease are utilized for treatment of egg white; total usage amount of lipase and composite protease is less than usage amount of individually used lipase or protease, and however, foamability and foam stability of egg white powder obtained by combined utilization of lipase and composite protease are higher than those of egg white powder obtained by individual utilization of lipase or composite protease; the egg white powder obtained in the invention can meet demands for high-grade products on the market, and the advantages of a simple process and high cost performance are achieved in the invention. According to the invention, the ratio of active usage amount of Aspergillus oryzae protease, papain and trypsin is determined to be 1:1:1; the usage amount and other technological parameters cooperatively allow egg white powder with high foamability to be obtained; egg white powder with high foamability provided in the invention enables the additional output value of eggs to be increased, lays a technical foundation for development and industrial production of special-purpose egg white powder products and increases economic benefits for enterprises.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Lens combination structure and machine vision lens with the structure

ActiveCN104360461BMeet the needs of high-end productsFlexible adjustment of clear apertureOptical elementsCamera lensMachine vision

The invention relates to the technical field of optical lenses and particularly relates to a lens combined structure. The lens combined structure comprises a first lens, a second lens, a third lens, a fourth lens, a diaphragm, a fifth lens, a sixth lens, a seventh lens and an eighth lens, center axes of which are positioned on the horizontal line, wherein the distance between the top of the front end surface of the eighth lens and the top of the rear end surface of the seventh lens is regulated between 0.1mm and 6mm. When the focal length is 25mm by virtue of the lens combined structure, the dimension of the corresponding chip is 2 / 3'', the pixel value of the lens combined structure can reach 5 millions of pixels, so that the high-end product needs are met, and the clear aperture of the lens combined structure can be flexibly regulated. Besides, the invention further discloses a machine visual lens with the lens combined structure.

Owner:GUANGDONG AOPUTE TECH CO LTD

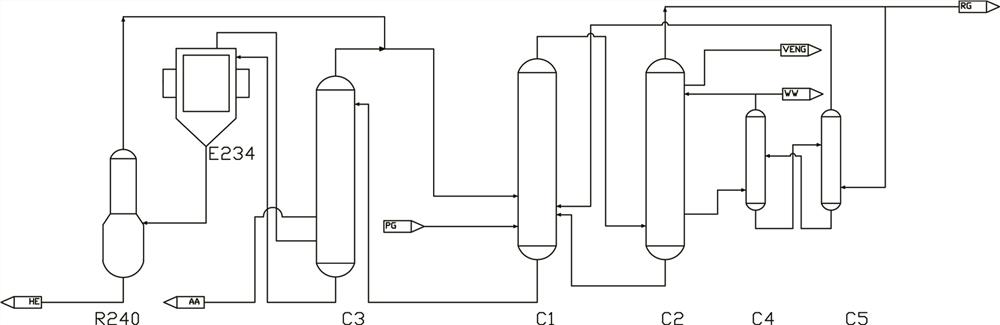

A kind of refining method of acrylic acid

ActiveCN109232232BSimple processLow investment costCarboxylic compound separation/purificationHigh concentrationAcid water

A method for refining acrylic acid, the process gas of acrylic acid is quenched and absorbed by high-concentration gas, reabsorbed by low-concentration gas, purified, extracted and stripped, and the cooling process, absorption process and purification process of the acrylic acid gas phase mixture are coupled, and carried out Subsequent acid water treatment is improved, the present invention improves the absorption process, no entraining agent is used in the refining process, less waste water is produced, the purity of the obtained acrylic acid is over 99.7%, the process is simple, the equipment investment cost and operating cost are low, and the production cost is low. The refining method of the present invention is simple, has remarkable practicability and economic benefits, and the obtained product has high purity and is easy for large-scale industrial production.

Owner:PINGHU PETROCHEM

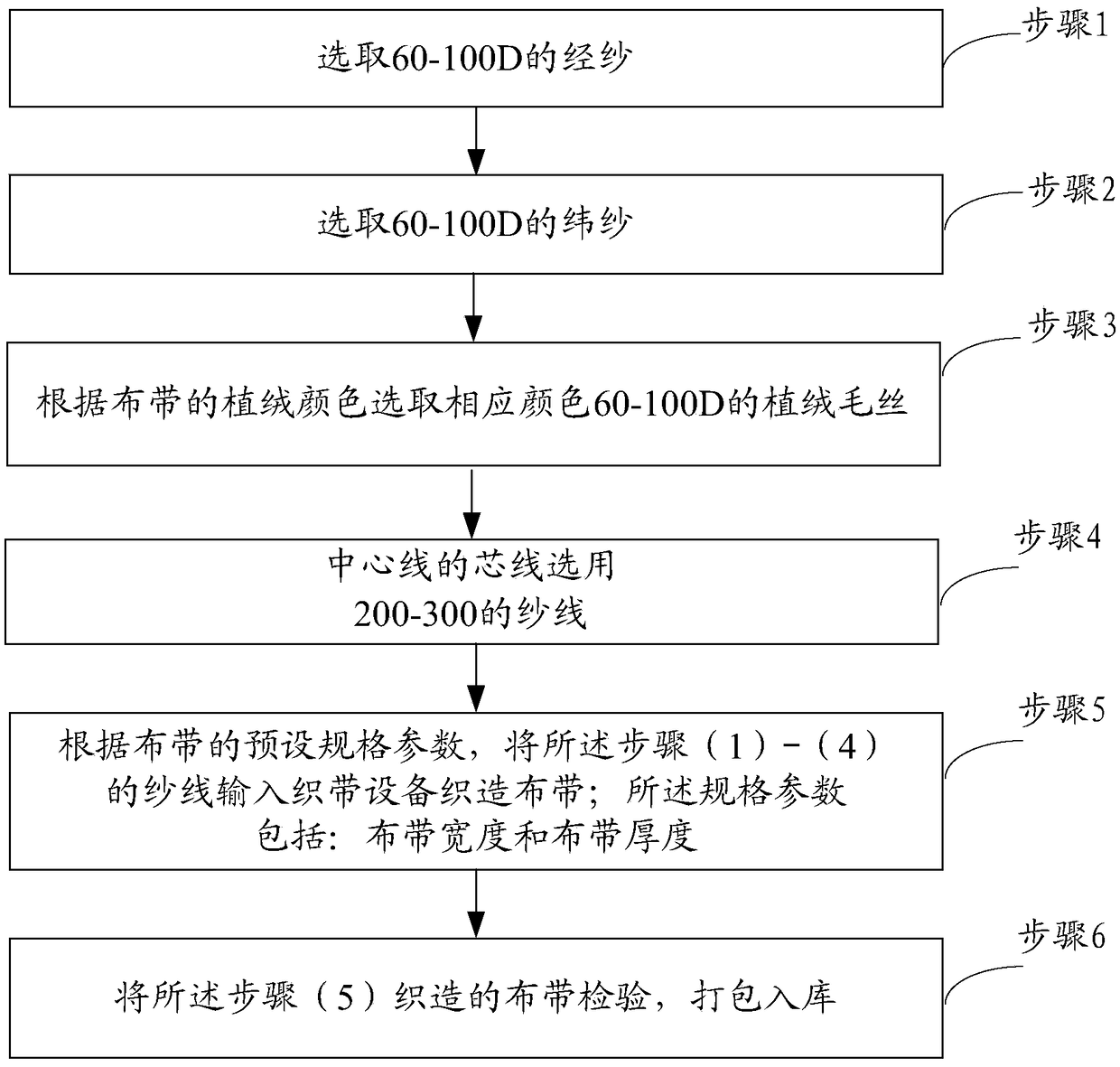

Manufacturing method of flocking zipper cloth strap

Owner:德诚拉链(东莞)有限公司

12mm fixed focus machine vision lens

ActiveCN105044882BAchieve focal lengthMeet the needs of high-end productsOptical elementsCamera lensMachine vision

Owner:GUANGDONG AOPUTE TECH CO LTD

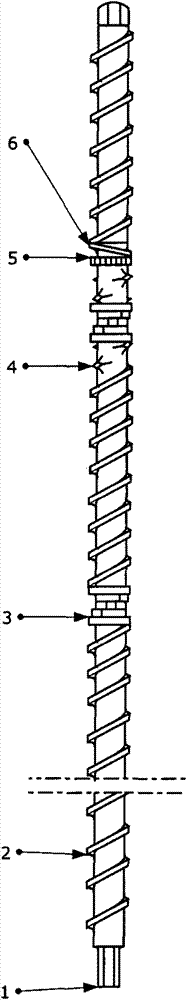

Heart valve type screw rod for color masterbatch production

The invention discloses a heart valve type screw rod which consists of structural elements of a screw rod mandrel (1), a threaded element (2), an elliptic blending block (3), a heart valve type kneading block (4), a tooth-shaped mixing disc (5), a back mixing helix (6) and the like, wherein an extrusion element is sleeved on the screw rod mandrel and is coupled with the screw rod mandrel in a spline manner. The pressure and the shearing force of the screw rod can be adjusted by changing or adjusting the combination modes of the extrusion elements according to characteristics of different materials, so as to achieve an expected dispersion effect.

Owner:CHANGZHOU HONGMEI PLASTIC MASTERBATCH +1

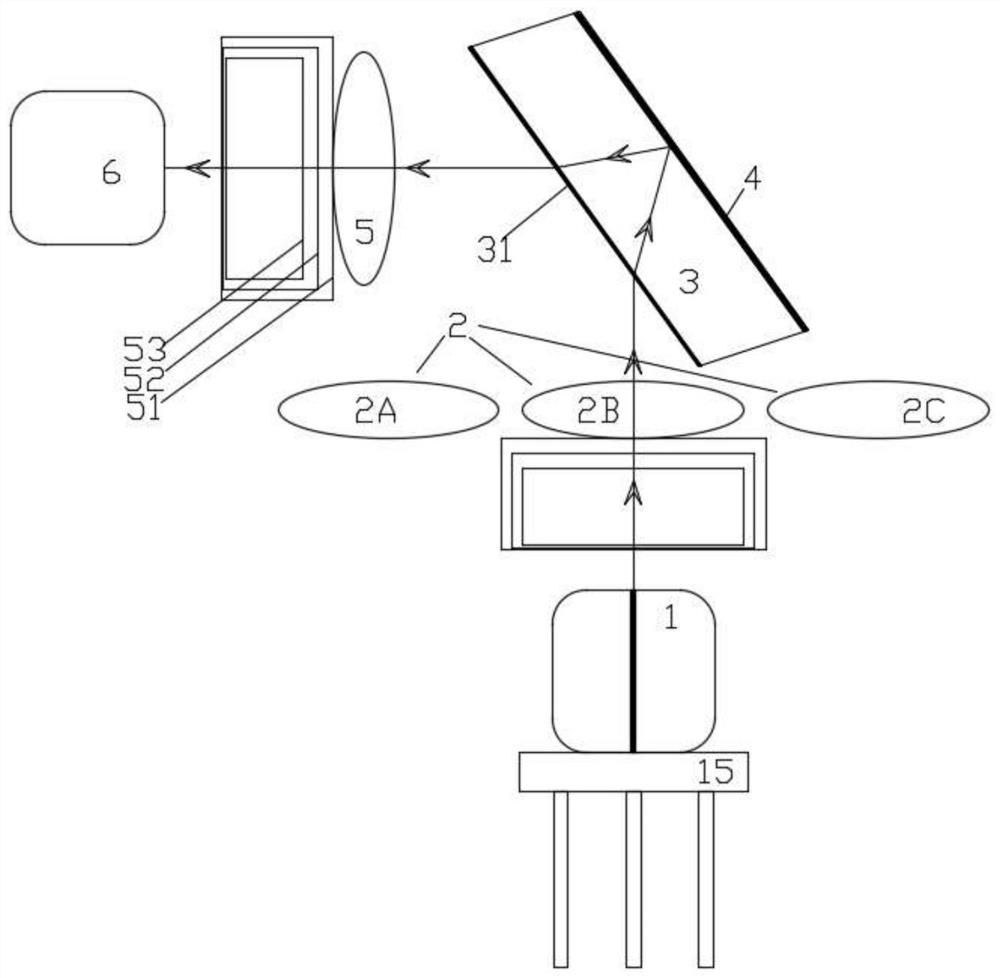

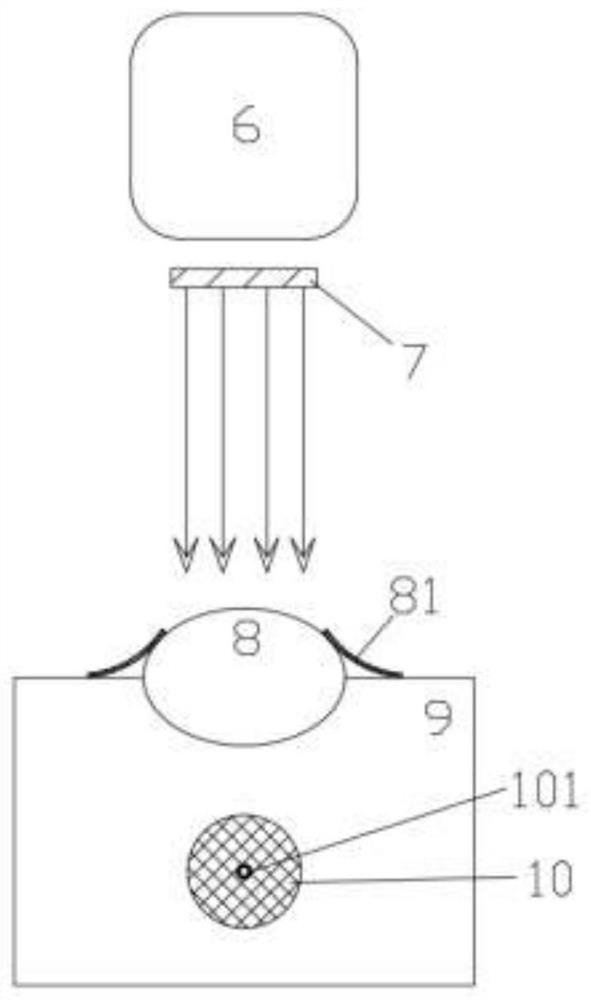

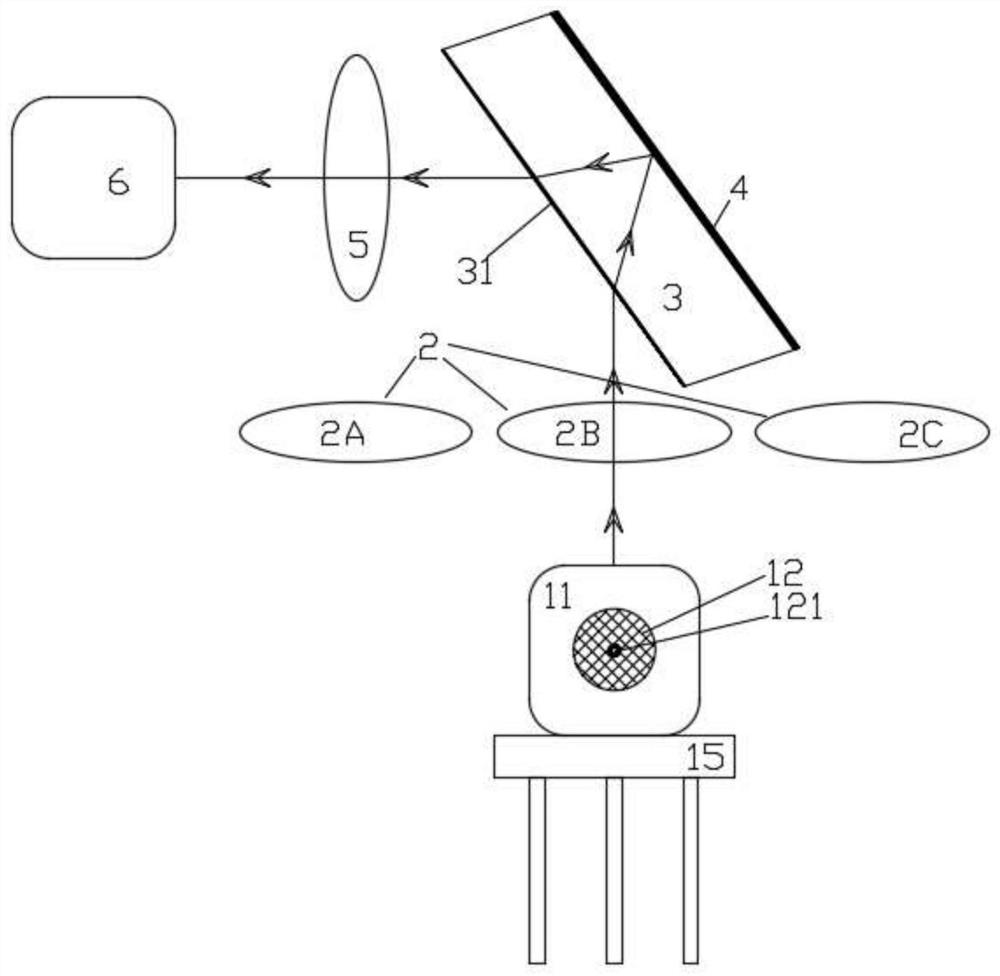

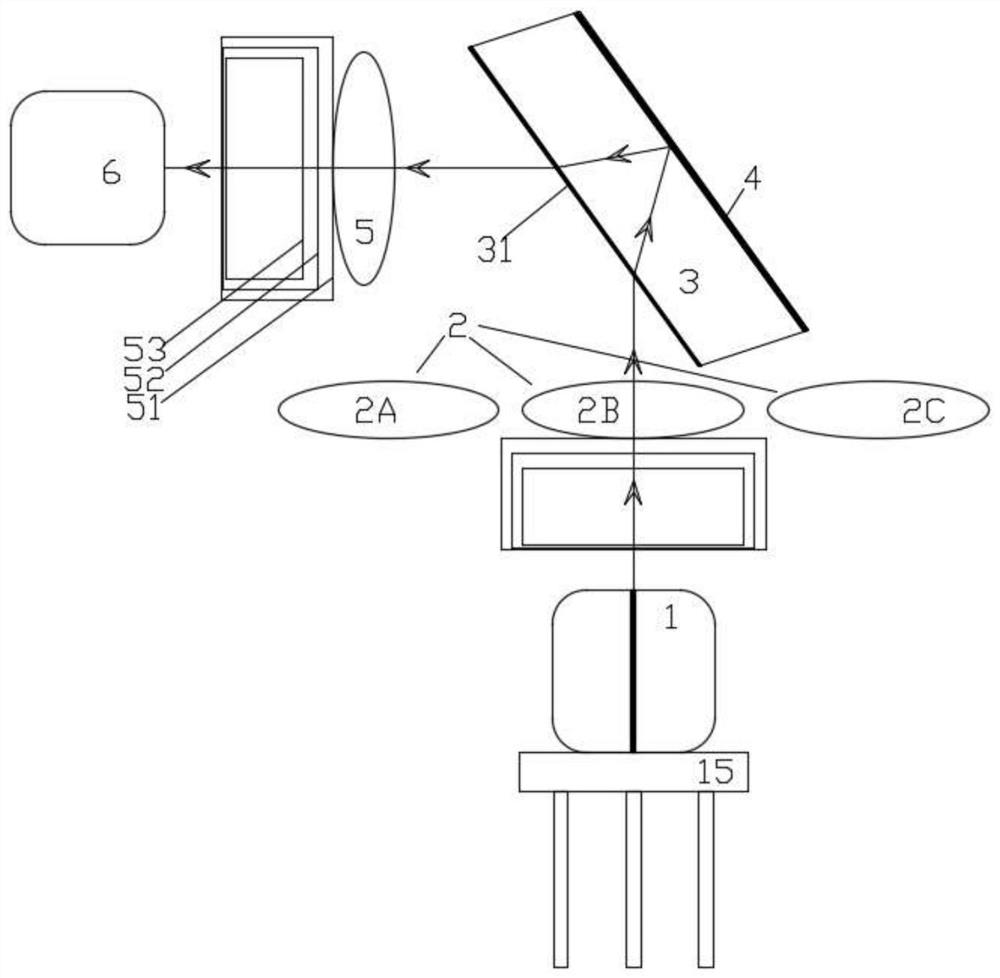

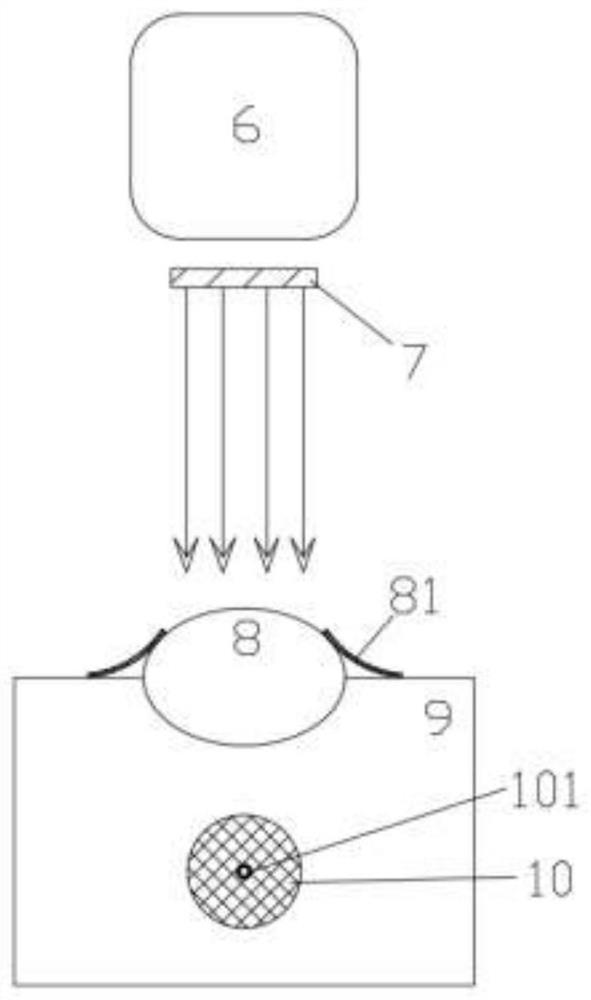

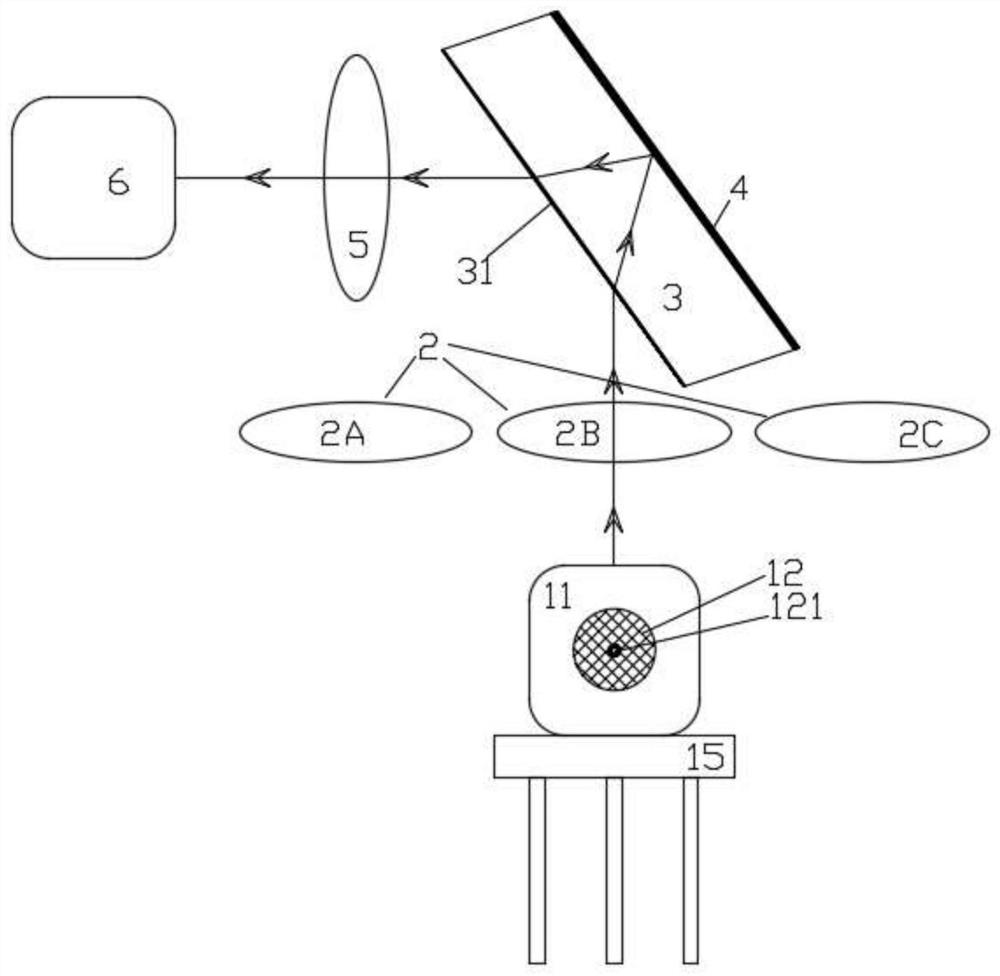

Visual cap sealing system and cap sealing method

ActiveCN113031193AHigh precisionGuaranteed accuracyLaser detailsUsing optical meansImage analysisLight Testing

The invention discloses a visual cap sealing system and a cap sealing method. The system comprises an image analysis device, a light path processing assembly, a light source, a convex lens and a target object. During cap sealing, a target object is fixed to the tube base, and the convex lens is fixed to the tube cap; the image analysis device obtains coordinates of the target object through the light path processing assembly and records the coordinates; the light source emits a test light path to the convex lens, and the position of the light source is adjusted to enable the test light path penetrating through the convex lens to form an emission lens light spot; a light spot center point of the convex lens is obtained and marked; the tube cap is directly faced to the tube seat according to the light spot center point of the convex lens and the coordinate of the target object, and then the cap sealing operation can be completed. According to the high-precision cap sealing scheme, a visual recognition scheme is adopted, the precision is high and can reach + / -10 microns, and the requirements of high-end products are completely met. According to the high-precision cap sealing scheme, the focal length can be adjusted, when different chip schemes are adopted, clear recognition is ensured by adjusting the focal length, and high precision is ensured.

Owner:GUILIN OPTOSEAL TECH CO LTD

Method for improving exposure uniformity of PCB

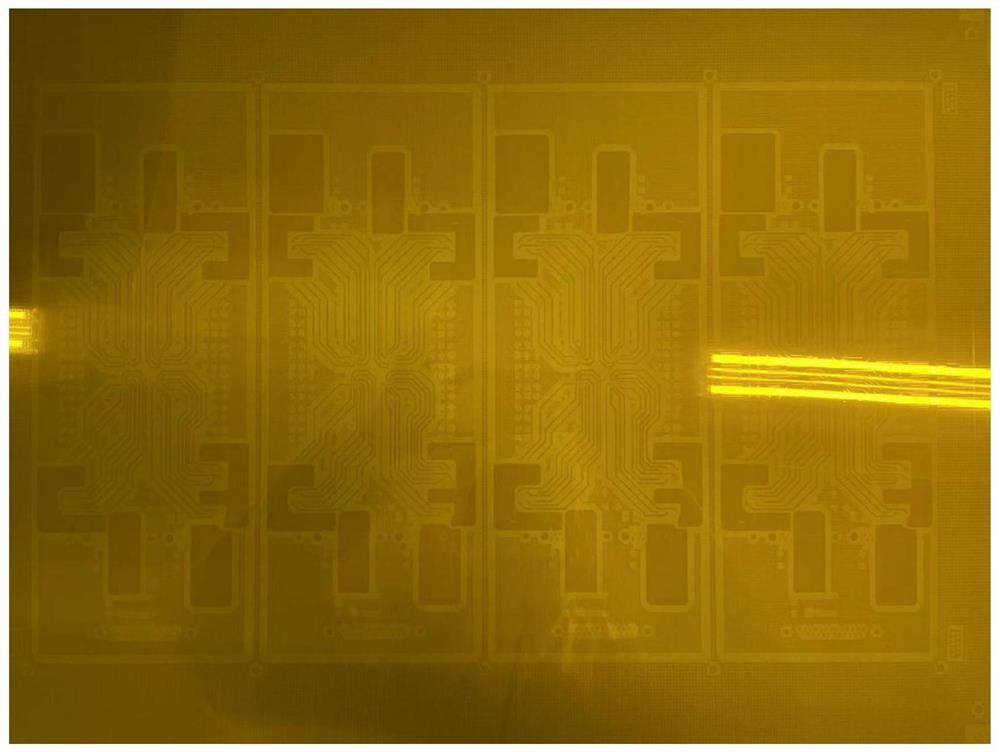

ActiveCN114706281ASolve open circuitSolve the problem of unclean film removalPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsModeling software

The invention provides a method for improving exposure uniformity of a PCB (Printed Circuit Board). The method comprises the following steps of: obtaining a theoretical thickness value of the PCB; measuring the thickness of each grid on the PCB; the difference value of each grid is imported into a data model established by modeling software from top to bottom and from left to right, and is visually displayed by adopting different colors; mask plates are prepared, each mask plate comprises a light-transmitting area and a light-proof area, and the light-transmitting area of each mask plate is matched with the area corresponding to the single color; the mask plates are adopted to expose the PCB one by one, the focal length of the exposure machine is adjusted according to different colors corresponding to the mask plates, and the exposure machine projects light penetrating through the light-transmitting area to the PCB for pattern transfer. The plate thickness distribution diagram can express the plate thickness distribution of the plate surface and the region, so that focal length adjustment of regional exposure during exposure is guided, exposure energy received by the whole plate surface is consistent, the risk of local overexposure or exposure deficiency is avoided, and the problem of circuit open circuit or incomplete film removal caused by inconsistent exposure energy is solved.

Owner:圆周率半导体(南通)有限公司

A visual capping system and capping method

ActiveCN113031193BHigh precisionMeet the needs of high-end productsLaser detailsUsing optical meansLight spotImaging analysis

The invention discloses a visual capping system and capping method: the system includes an image analysis device, an optical path processing component, a light source, a convex lens and an object. When sealing the cap, fix the target object on the tube base and the convex lens on the tube cap; the image analysis device obtains and records the coordinates of the target object through the optical path processing component; the light source emits a test light path to the convex lens, and adjusts the position of the light source so that the Test the optical path to form the emission lens spot; get the center point of the spot of the convex lens and mark it; according to the center point of the spot of the convex lens and the coordinates of the target, make the tube cap face the tube seat; the capping operation can be completed. The high-precision cap sealing scheme of the present invention adopts a visual recognition scheme, and has high precision, which can reach ±10um, and fully meets the needs of high-end products. The focal length of the high-precision capping solution of the present invention can be adjusted. When different chip solutions are used, the focal length can be adjusted to ensure clear identification and high precision.

Owner:GUILIN OPTOSEAL TECH CO LTD

3x zoom machine vision lens

ActiveCN106094181BMeet the needs of high-end productsFlexible adjustment of clear apertureOptical elementsCamera lensMachine vision

The invention discloses a 3X zoom machine vision lens. The 3X zoom machine vision lens comprises a lens combination structure; the lens combination structure includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a diaphragm, a seventh lens, an eighth lens, a ninth lens, a tenth lens, an eleventh lens, a twelfth lens and a thirteenth lens; the axes of the first lens, the second lens, the third lens, the fourth lens, the fifth lens, the sixth lens, the diaphragm, the seventh lens, the eighth lens, the ninth lens, the tenth lens, the eleventh lens, the twelfth lens and the thirteenth lens are located on the same horizontal line; the first lens, the second lens and the third lens constitute a first lens group; the fourth lens, the fifth lens and the sixth lens constitute a second lens group; the seventh lens, the eighth lens, the ninth lens and the tenth lens constitute a third lens group; and the eleventh lens, the twelfth lens and the thirteenth lens constitute a fourth group. According to the 3X zoom machine vision lens of the invention, the first lens group, the second lens group, the third lens group and the fourth group cooperate with one another, so that the pixel value of the 3X zoom machine vision lens can achieve 5 million pixels when a working distance is 90mm, and the size of a corresponding chip is 2 / 3, and therefore, the requirements of high-end products can be satisfied; and the light passing aperture of the 3X zoom machine vision lens can be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

16mm fixed focus machine vision lens

ActiveCN105044883BAchieve focal lengthMeet the needs of high-end productsOptical elementsCamera lensMachine vision

The invention relates to the technical field of optical mirrors, in particular to a 16mm fixed-focus machine vision lens, comprising a first lens, a second lens, a third lens, a fourth lens, a diaphragm, a fifth lens, and a sixth lens whose central axes are located on the same horizontal line. Lens, the seventh lens and the eighth lens, when the object distance changes, the air distance between the eighth lens and the image plane changes, that is, the first lens to the eighth lens move back and forth together, only the optical back focus changes, and the other distances Dimensions do not change. Through the above structure, when the focal length is 16mm and the corresponding chip size is 2 / 3", its pixel value can reach 5 million pixels, which meets the needs of high-end products, and its clear aperture can also be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

Processing method for fine gilding and overprinting in large size

ActiveCN102887000BFine printing effectThe printing effect is beautifulOther printing apparatusLine widthLarge size

The invention discloses a processing method for fine gilding and overprinting in large size. The processing method comprises the following steps of: color matching: adjusting the ground color for printing and the colors of printing patterns, wherein tones of the same color system are adopted, and alumite stamping foil adopts the tone the same with those of the ground color for printing and the colors of the printing patterns; graphic processing: carrying out virtual-edge adding or feathering treatment on the printing patterns by adopting software; shape adjusting: adjusting the gilding shape to be an irregular shape for a circular arc shape; line width and space adjusting: adjusting line width and space between the patterns of the patterns to be gilded; and making a gilding plate, during plate making, the gilding plate is compressed in proportions. With the adoption of the processing method for fine gilding and overprinting in large size, the printing effect is more fine and more attractive than that of the prior art, the requirements for high-grade product can be met, and the processing method can adapt to mass production, has lower cost than the traditional technology, and improved yield.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

35mm fixed focus machine vision lens

ActiveCN104360459BMeet the needs of high-end productsCompact structureOptical elementsConvex structureCamera lens

The invention belongs to the technical field of machine vision camera lenses and particularly relates to a machine vision camera lens with a 35mm fixed focus. The machine vision camera lens comprises a first lens with a concave-convex structure, a second lens with a concave-convex structure, a third lens with a concave-convex structure, a fourth lens with a concave-convex structure, a fifth lens with a double-concave structure, a sixth lens with a double-convex structure, a seventh lens with a double-convex structure, an eighth lens with a concave-convex structure and a ninth lens with a concave-convex structure, wherein the first lens, the second lens, the third lens, the fourth lens, the fifth lens, the sixth lens, the seventh lens, the eighth lens and the ninth lens are sequentially arranged in a way that the central shafts are coaxial along the light-incident direction; due to the combination of the nine lenses, the pixel value of the camera lens with the 35mm focus can be up to 5 megapixels when the size of a corresponding chip is 2 / 3', so that the high-end product demand is met; and meanwhile, the clear aperture is adjustable within the range of F1.4-F16. The machine vision camera lens with the 35mm fixed focus is compact in structure, convenient to assemble and capable of reducing the production cost.

Owner:GUANGDONG AOPUTE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com