Machine vision lens and imaging method with large field of view and large aperture

A machine vision, large-aperture technology, used in instruments, optical components, optics, etc., can solve the problems of unable to meet the needs of high-end products, unable to meet the large field of view, large aperture, low distortion, high resolution, etc., and achieve low distortion. , to meet the needs of high-end products, the effect of large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

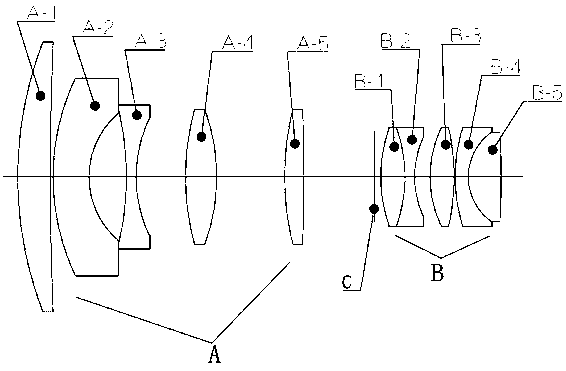

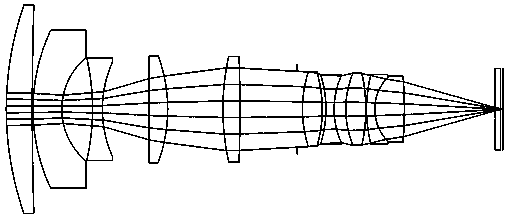

[0039] In this embodiment, the optical system data is as follows:

[0040] optical surface Radius (mm) Thickness (mm) Refractive index Abbe number 1 41.650 3.63 1.70 56.20 2 404.854 0.31 3 25.643 4.00 1.88 40.81 4 9.290 4.15 5 -32.362 1.10 1.85 30.06 6 15.304 6.48 7 1823.039 2.46 1.69 53.35 8 -21.825 7.57 9 31.052 2.15 1.92 20.88 10 -206.986 7.83 aperture Infinity 0.74 12 16.357 2.66 1.51 60.48 13 -16.391 1.10 1.76 27.55 14 10.569 1.71 15 12.625 2.67 1.69 49.23 16 -24.689 0.12 17 18.171 1.46 1.75 35.02 18 6.102 3.65 1.53 60.47 19 -81.242 12.91 Image surface Infinity

[0041] In this embodiment, the focal length of the optical system is 8.5 mm.

[0042] In this embodiment, lens A-4 is a biconvex lens.

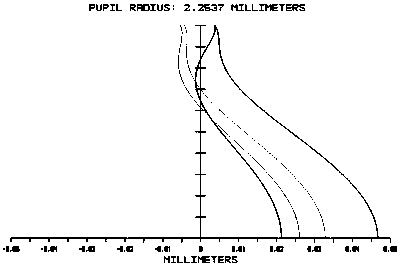

[0043] The focus data table is as follows:

[0044]

[0045] In this...

Embodiment 2

[0052] In this embodiment, the optical system data is as follows:

[0053] optical surface Radius (mm) Thickness (mm) Refractive index Abbe number 1 31.116 2.53 1.70 56.2 2 329.675 0.07 3 18.138 2.81 1.88 40.8 4 6.597 3.00 5 -22.319 0.96 1.85 30.1 6 11.430 4.57 7 Infinity 1.80 1.69 53.3 8 -15.085 5.39 9 23.858 1.66 1.92 20.9 10 -147.834 5.58 aperture Infinity 0.51 12 12.011 1.93 1.51 60.5 13 -12.926 0.36 14 -11.285 0.79 1.76 27.5 15 8.001 1.14 16 9.305 1.95 1.69 49.2 17 -16.114 0.07 18 13.815 0.79 1.75 35.0 19 4.470 2.89 1.53 60.5 20 -41.272 9.38 Image surface Infinity

[0054] In this embodiment, the focal length of the optical system is 6 mm.

[0055] In this embodiment, lens A-4 is a plano-convex lens.

[0056] The focus data table is as follows:

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com