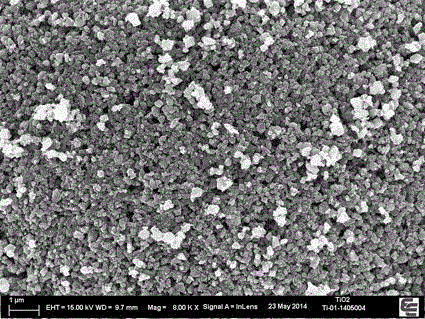

Preparation method of titanium dioxide with high specific surface area

A technology of titanium oxychloride and titanium tetrachloride, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high production cost, poor product quality, environmental pollution, etc., to prevent agglomeration, prevent particle agglomeration, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

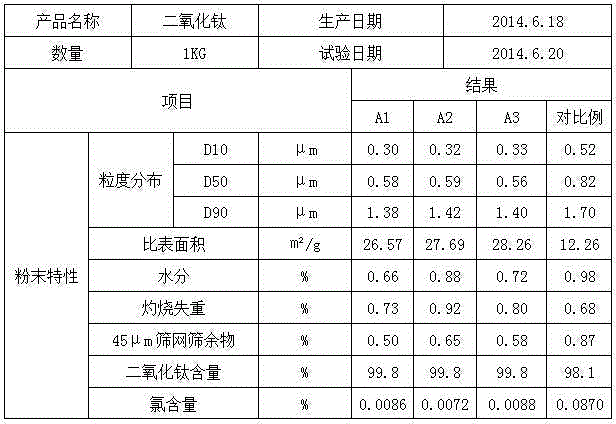

[0014] Example 1: Add 3mol of titanium tetrachloride slowly to 1L of deionized water to dissolve, and control the dissolution to stabilize below 60°C to obtain a 3mol / L titanium oxychloride solution; under continuous stirring, add to the above solution Add a mixture of polyvinyl alcohol, ethanolamine, citric acid, and triol silane (1:2:1:2) with a total mass of 5‰ of the solution; gradually increase the temperature to 70°C, add 9mol / L liquid ammonia to the above solution; gradually After heating to 90°C, holding for 2 hours to obtain a metatitanic acid gel, which is filtered to obtain a metatitanic acid filter cake; add the filter cake to the calciner for calcination, control the calcination temperature at 750°C, and take it out after calcination for 2 hours , Pulverize and pass through a screen of more than 60 meshes to obtain titanium dioxide powder; after adding the above powder to a ball mill for ball milling 20 times, it is screened through an 80-mesh screen, and those that...

Example Embodiment

[0016] Example 2: Add 3.2 mol of titanium tetrachloride slowly to 1L of deionized water to dissolve, and control the stability of the dissolution to be below 60°C to obtain a 3.2mol / L titanium oxychloride solution; under the condition of continuous stirring, Add a mixture of polyvinyl alcohol, ethanolamine, citric acid, and triol silane (1:2:1:2) with a total mass of 6‰ to the solution; when the temperature is gradually increased to 70°C, add 9.1mol / L to the above solution Ammonia; Gradually increase the temperature to 92°C and keep it for 3 hours to obtain a metatitanic acid gel, which is then filtered to obtain a metatitanic acid filter cake; add the filter cake to the calcining furnace for calcination, control the calcination temperature at 800°C, and calcine 3 After hours, take it out, pulverize, and pass through a screen of more than 60 meshes to obtain titanium dioxide powder; after adding the above powder to a ball mill for 20 times, it is screened by an 80-mesh screen, a...

Example Embodiment

[0018] Example 3: Add 3.5mol of titanium tetrachloride slowly to 1L of deionized water to dissolve, and control the stability of the dissolution to be below 60°C to obtain a 3.5mol / L titanium oxychloride solution; under continuous stirring conditions, Add a mixture of polyvinyl alcohol, ethanolamine, citric acid, and triolsilane (1:2:1:2) with a total mass of 7‰ to the solution; when the temperature is gradually increased to 70°C, add 9.2mol / L of liquid to the above solution Ammonia; After gradually raising the temperature to 95°C, keep it for 4 hours to obtain a metatitanic acid gel, and obtain a metatitanic acid filter cake by pressure filtration; add the filter cake to the calcination furnace for calcination, control the calcination temperature at 900°C, and calcine 4 After hours, take it out, pulverize, and pass through a screen of more than 60 meshes to obtain titanium dioxide powder; after adding the above powder to a ball mill for 20 times, it is screened by an 80-mesh sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com