Grapheme composite membrane, preparing method thereof and functions thereof

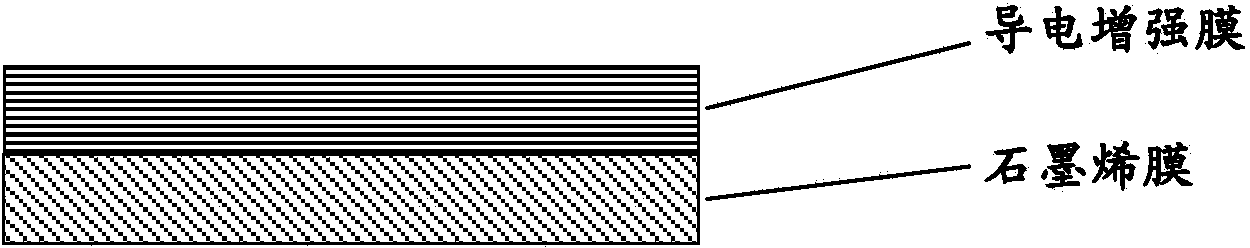

A graphene composite and graphene film technology, applied in cable/conductor manufacturing, conductive materials, conductors, etc., can solve the problems of incomplete graphene growth, brittle ITO, easy to wear, etc., to avoid defects and tiny Damage, simple and easy process, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1) Preparation of graphene film

[0072] After cutting the base copper foil to size, place it on the mold and put it into the deposition tube of the deposition furnace. Close the flanges at both ends of the deposition tube, evacuate to below 5pa, and check the air leakage of the equipment. Introduce argon gas into the deposition tube, after reaching normal pressure, turn off the argon gas, evacuate to 5 Pa, repeat twice, wherein the flow rate of argon gas is 2000 sccm.

[0073] Under the protection of argon, the temperature of the equipment was raised to 1000°C, wherein the argon flow rate was 1000 sccm, and the heating rate of the equipment was 10°C / min. After the temperature reaches 1000°C, feed methane and hydrogen gas into the deposition tube to deposit graphene, wherein the flow rate of methane is 20 sccm, the flow rate of hydrogen gas is 200 sccm, the deposition time is 20 min, and the graphene film is obtained after cooling.

[0074] 2) Preparation of conductiv...

Embodiment 2

[0081] 1) Preparation of graphene film

[0082] After cutting the base copper foil to size, place it on the mold and put it into the deposition tube of the deposition furnace. Close the flanges at both ends of the deposition tube, evacuate to below 5pa, and check the air leakage of the equipment. Pass the mixed gas of argon and nitrogen into the deposition tube, after reaching normal pressure, turn off the argon, evacuate to 5pa, repeat twice, wherein the flow rate of argon gas is 2000 sccm, and the flow rate of nitrogen gas is 2000 sccm.

[0083] Under the protection of argon, the temperature of the equipment was raised to 900°C, wherein the argon flow rate was 1500 sccm, and the heating rate of the equipment was 8°C / min. After the temperature reaches 900°C, feed ethylene and hydrogen gas into the deposition tube to deposit graphene, wherein the flow rate of ethylene is 10 sccm, the flow rate of hydrogen gas is 200 sccm, the deposition time is 15 min, and a graphene film is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com