Manufacturing method of flocking zipper cloth strap

A manufacturing method and technology for tapes, which are applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of poor appearance and texture of webbing, fading, and reduced beauty of webbing, and achieve friction resistance, smoothness, no gaps, soft hand feel, and three-dimensionality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

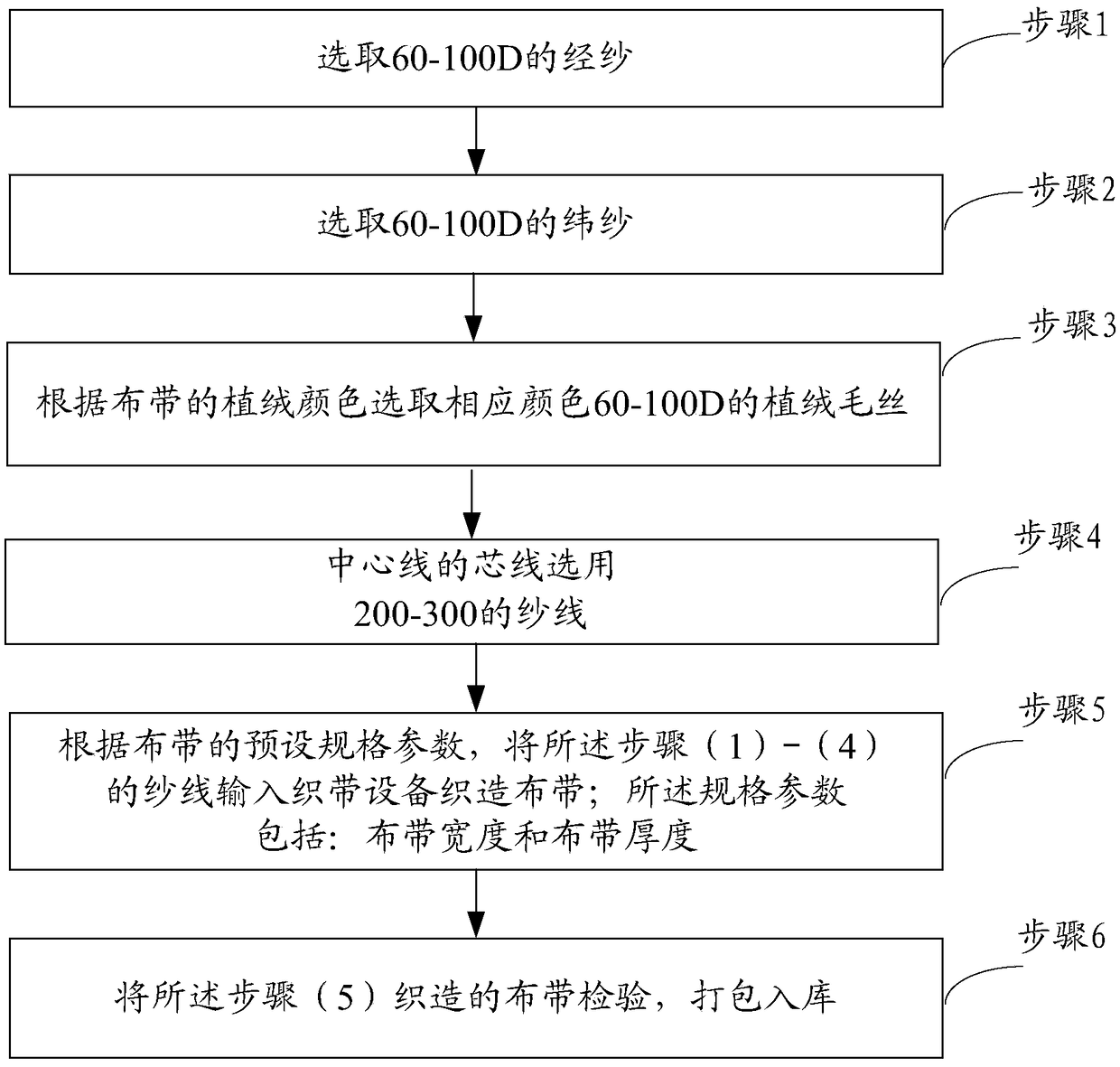

[0035] Step 1: Choose 60 pieces of black 70D / 1 polyester light mesh DTY for the warp; (D refers to the textile fiber measurement unit, indicating the thickness of the fiber);

[0036] Step 2: Use 2 pieces of black 70D / 1 polyester light mesh DTY for the weft;

[0037] Step 3: Select 45 black 66D yarns for surface flocking;

[0038] Step 4: Choose a braided center thread for the center line; (all zipper center lines are all woven with yarn) The center line of the center line uses 2 white 300D / 1 polyester heavy mesh DTY and 3 white 300D / 1 nylon TDY ;

[0039] Step 5: According to the first step to the fourth step of the above-mentioned product design plan, weave the tape on the electrostatic tape flocking machine, and adjust the width of the tape to 15.5mm; Features, so that the fluff is negatively charged, and the cloth tape that needs to be flocked is placed at zero potential or grounded, and the fluff is attracted by the plant body under the different potential, and is attra...

Embodiment 2

[0046] Step 1: Choose 60 pieces of black 60D / 1 polyester light mesh DTY for the warp;

[0047] Step 2: Use 2 pieces of black 60D / 1 polyester light mesh DTY for the weft;

[0048] Step 3: Select 45 black 66D yarns for surface flocking;

[0049] Step 4: Choose a braided center thread for the center thread; use 2 white 200D / 1 polyester heavy net DTY and 3 white 200D / 1 nylon TDY for the center thread;

[0050] Step 5: According to the first step to the fourth step of the above-mentioned product design plan, weave the tape on the electrostatic tape flocking machine. The width of the tape is adjusted to 16mm; the thickness is 4mm. Using the physical characteristics of the same-sex repulsion and opposite-sex attraction, Make the fluff negatively charged, place the cloth tape that needs flocking at zero potential or ground, the fluff is attracted by the plant body under the different potential, and is attracted vertically to the surface of the cloth tape that needs flocking;

[0051...

Embodiment 3

[0053]Step 1: Choose 60 pieces of black 100D / 1 polyester light mesh DTY for the warp;

[0054] Step 2: Choose 2 pieces of black 100D / 1 polyester light mesh DTY for the weft;

[0055] Step 3: Select 45 black 66D yarns for surface flocking;

[0056] Step 4: Choose a braided center thread for the center thread; use 2 white 250D / 1 polyester heavy net DTY and 3 white 250D / 1 nylon TDY for the center thread;

[0057] Step 5: According to the first step to the fourth step of the above-mentioned product design plan, weave the tape on the electrostatic tape flocking machine, and adjust the width of the tape to 16.5mm; Features, so that the fluff is negatively charged, put the cloth tape that needs to be flocked at zero potential or ground, the fluff is attracted by the plant body under the different potential, and is attracted to the surface of the cloth tape that needs to be flocked at a vertical speed;

[0058] Step 6: Do a good job of quality inspection during production, and pack ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com