Method for controlling carbide banded structure of high-carbon chromium bearing steel

A high-carbon chromium bearing steel, control method technology, applied in the direction of rolling force/roll gap control, metal rolling, etc., can solve the problem of unstable carbide band level control, inability to stably satisfy high-end customers, insufficient dissolution, etc. problems, to stably control the carbide band level, improve composition uniformity, and reduce composition segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

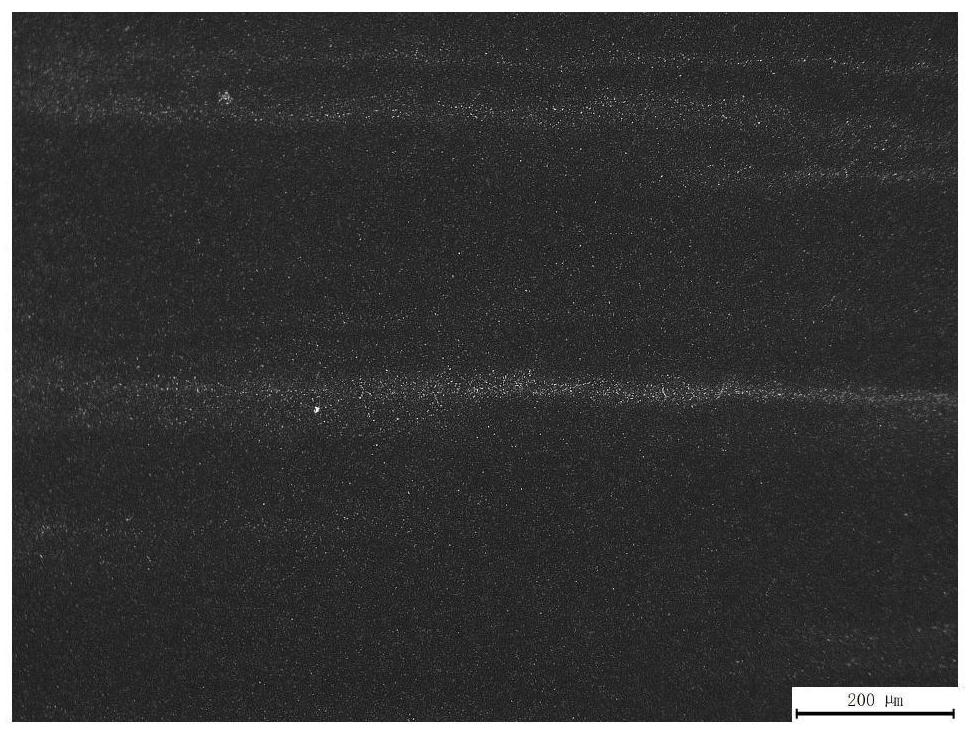

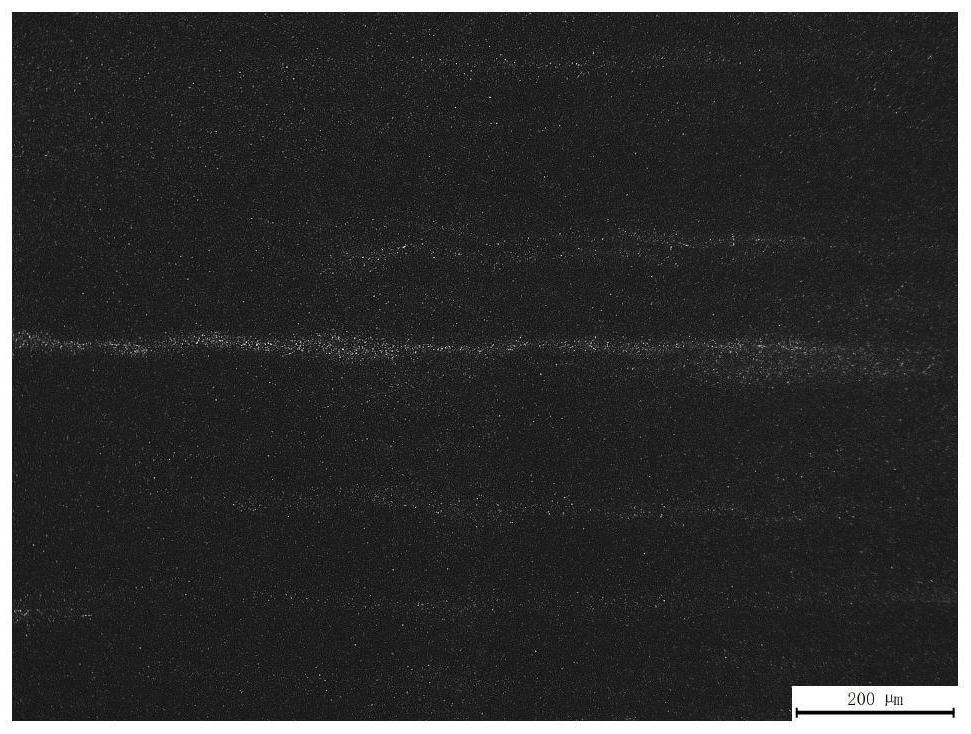

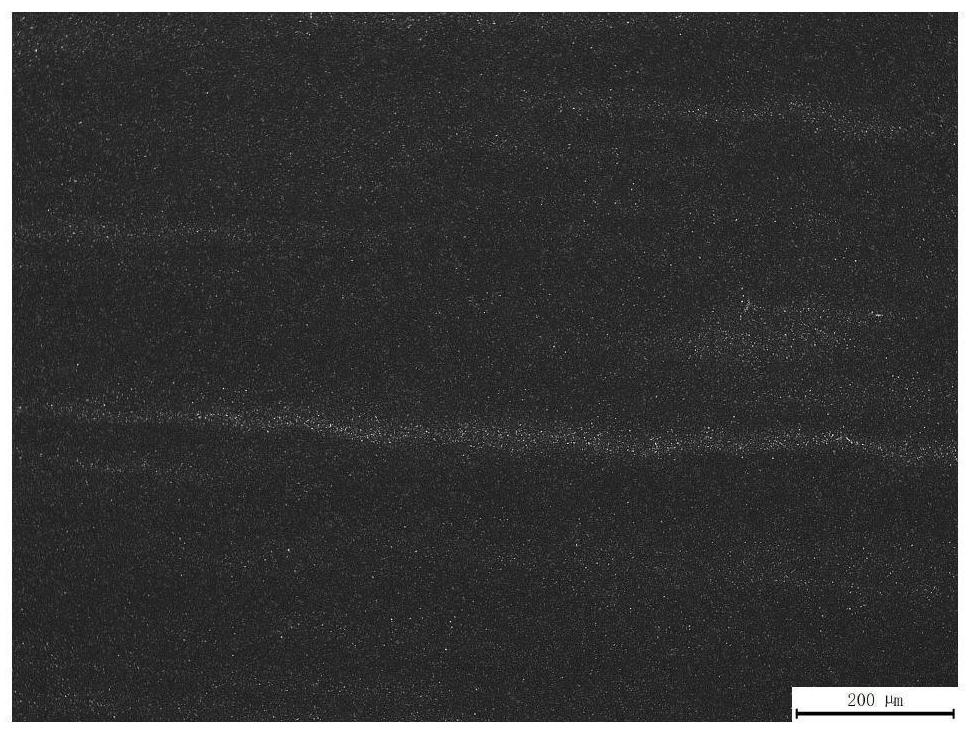

Image

Examples

Embodiment 1

[0085] Step a: billet continuous casting: using mold electromagnetic stirring and final light reduction process, mold electromagnetic stirring stirring current is 400A, stirring frequency is 2.5Hz; terminal electromagnetic stirring current is 600A, stirring frequency is 5.0Hz; control terminal light The total reduction is 16mm; the specific water volume is controlled at 0.22L / Kg; at the same time, the casting speed is controlled at 0.62m / min, and the superheat is 21°C;

[0086] Step b: Place the billet in a heating furnace for a high-temperature diffusion, wherein the heating temperature of the high-temperature section is controlled at 1226°C, and the total heating time is controlled at 510 minutes, of which the time of the high-temperature section is 280 minutes;

[0087] Step c: Carry out slab rolling to the slab, and control the slab slab opening process into seven passes, of which the first three passes adopt a large reduction process, and the reduction rates of the first to ...

Embodiment 2

[0089] Step a: billet continuous casting: using mold electromagnetic stirring and final light reduction process, mold electromagnetic stirring stirring current is 400A, stirring frequency is 2.5Hz; terminal electromagnetic stirring current is 600A, stirring frequency is 5.0Hz; control terminal light The total reduction is 16mm; the specific water volume is controlled at 0.22L / Kg; at the same time, the casting speed is controlled at 0.62m / min, and the superheat is 25°C;

[0090] Step b: Place the billet in a heating furnace for a high-temperature diffusion, wherein the heating temperature of the high-temperature section is controlled at 1230°C, and the total heating time is controlled at 505 minutes, of which the time of the high-temperature section is 270 minutes;

[0091] Step c: Carry out slab rolling to the slab, and control the slab slab opening process into seven passes, of which the first three passes adopt a large reduction process, and the reduction rates of the first t...

Embodiment 3

[0093] Step a: billet continuous casting: using mold electromagnetic stirring and final light reduction process, mold electromagnetic stirring stirring current is 400A, stirring frequency is 2.5Hz; terminal electromagnetic stirring current is 600A, stirring frequency is 5.0Hz; control terminal light The total reduction is 16mm; the specific water volume is controlled at 0.22L / Kg; at the same time, the casting speed is controlled at 0.62m / min, and the superheat is 15°C;

[0094] Step b: Place the billet in a heating furnace for a high-temperature diffusion, wherein the heating temperature of the high-temperature section is controlled at 1248°C, and the total heating time is controlled at 550 minutes, of which the time of the high-temperature section is 320 minutes;

[0095] Step c: Carry out slab rolling to the slab, and control the slab slab opening process into seven passes, of which the first three passes adopt a large reduction process, and the reduction rates of the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com