A kind of refining method of acrylic acid

A refining method, acrylic acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of high acrylic acid content, increased environmental protection costs, increased production costs, etc., to achieve low steam consumption, reduced production costs, and environmental protection low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

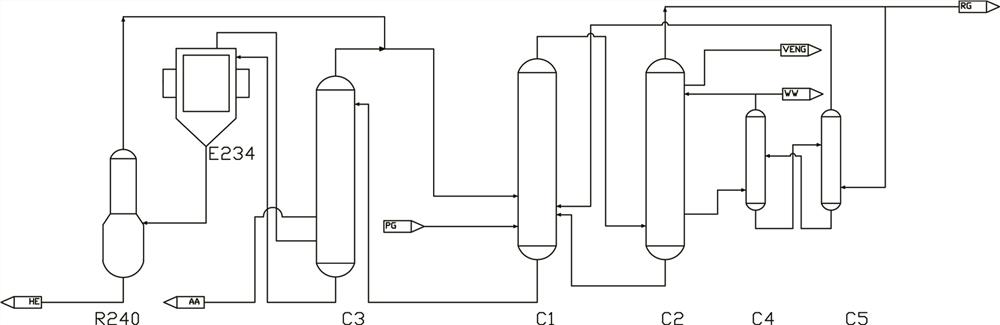

[0050] A refining method for acrylic acid, comprising the following steps:

[0051] 1) Quenching absorption

[0052] The acrylic acid process gas PG from the upstream enters the lower part of the absorption tower C1, and contacts with the absorbent and the circulating stream in the tower bottom for rapid cooling and absorption. The acrylic acid, part of the acetic acid and water in the process gas are cooled and absorbed to become the absorption liquid, Discharge, the heating temperature of the tower kettle is 80°C;

[0053] The uncooled gas phase in the process gas goes up in the absorption tower C1, and passes through the spray liquid during the upward process to absorb the acrylic acid, acetic acid and water in it, and the remaining gas phase is discharged from the top of the absorption tower C1;

[0054] 2) Reabsorption

[0055] The gas phase discharged from the top of the absorption tower C1 enters the lower part of the light removal tower C2, and the bottom of the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com