Lens combination structure and machine vision lens with the structure

A combined structure and lens technology, applied in the field of optical mirrors, can solve the problems of less than 5 million pixels and cannot meet the needs of high-end products, and achieve the effect of meeting the needs of high-end products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

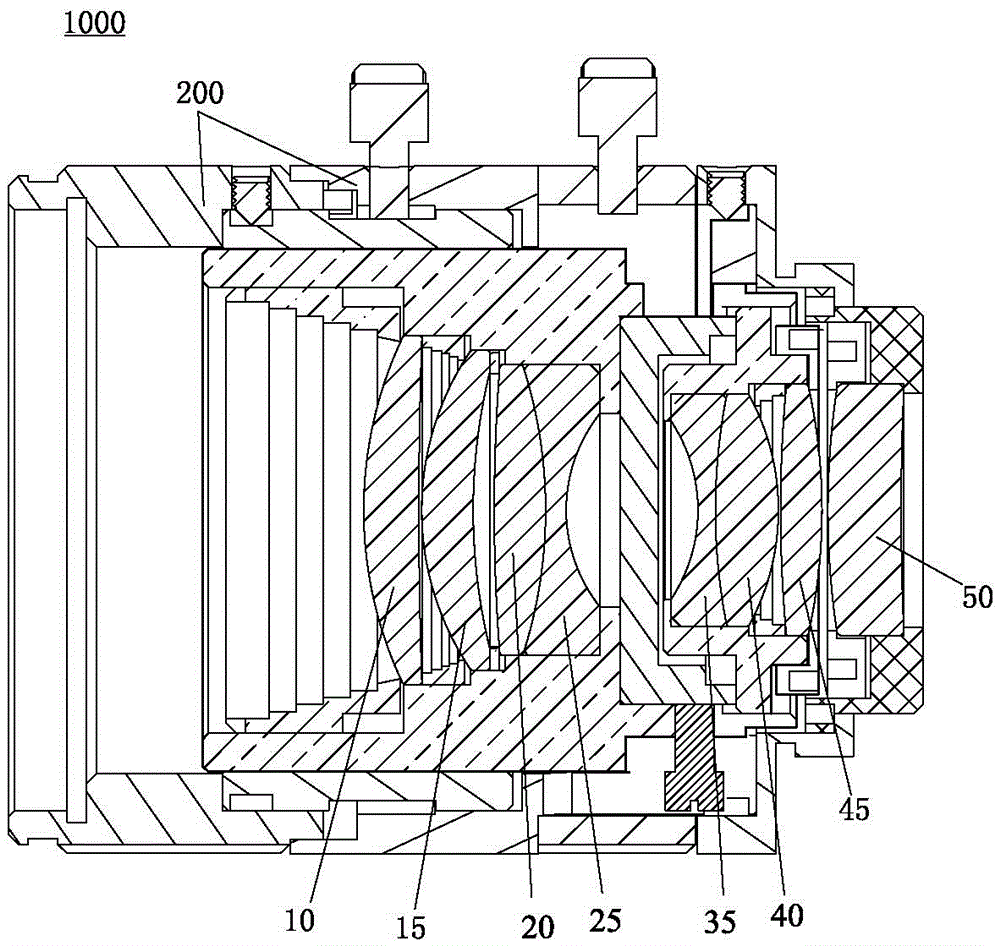

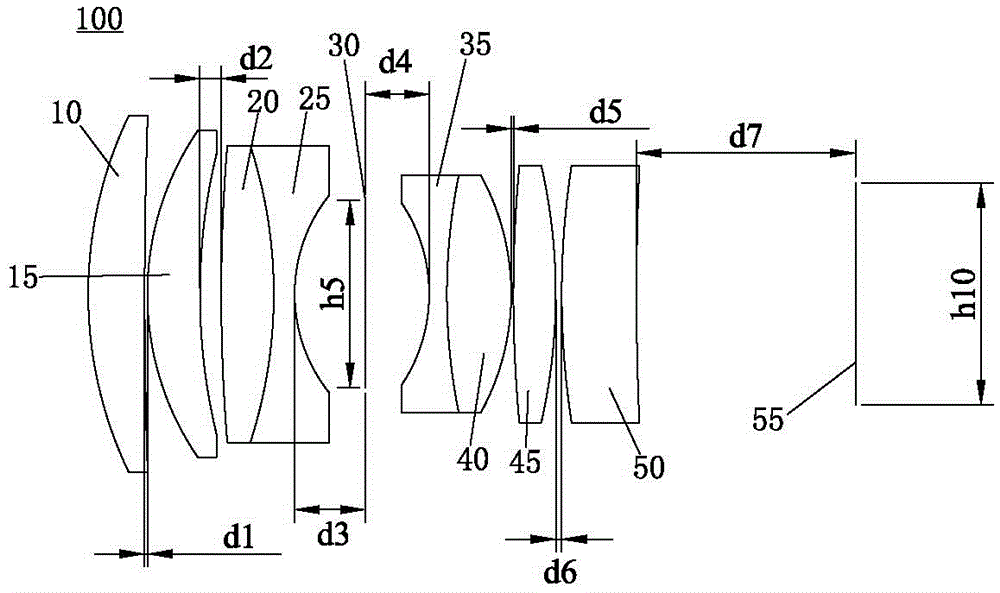

[0025] refer to Figure 1 to Figure 10 , the machine vision lens 1000 of the present invention includes a lens barrel 200 and a lens combination structure 100 , and the lens combination structure 100 is installed in the lens barrel 200 .

[0026] Wherein, the lens combination structure 100 includes a first lens 10, a second lens 15, a third lens 20, a fourth lens 25, a diaphragm 30, a fifth lens 35, a sixth lens 40, a seventh lens whose central axes are located on the same horizontal line. The lens 45 and the eighth lens 50 .

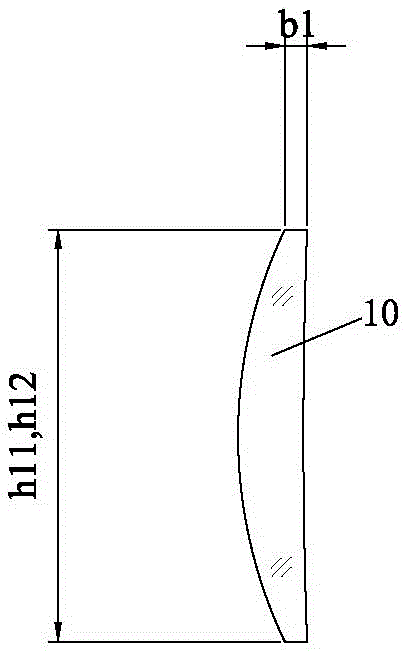

[0027]The front end surface of the first lens 10 is a convex surface with a radius of 20.832 ± 0.1 millimeters, the side wall thickness b1 of the first lens 10 is 0.96 ± 0.1 millimeters, the height h11 of the front end surface of the first lens 10 and the height h12 of the rear end surface are both 18 ± 0.1 mm, the rear end surface of the first lens 10 is a concave surface with a radius of 255.31 ± 0.1 mm; the front end surface of the second lens 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com