Reinforcing ring structure, preparation process and application thereof

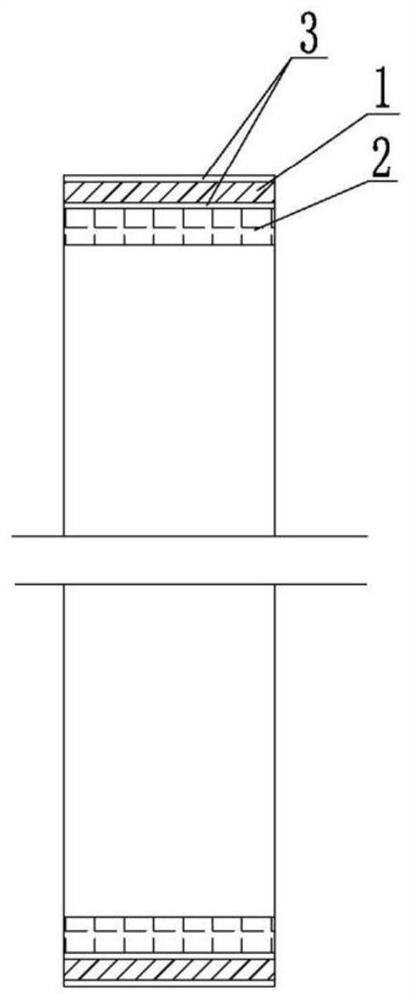

A preparation process and reinforcement ring technology, applied in the shape/style/structure of winding insulation, epoxy resin coating, electromechanical devices, etc., can solve the problem of difficulty in reaching the extreme output torque of starters, poor insulation performance of steel reinforcement rings, steel Insufficient strength of the permanent reinforcement ring and the armature coil, etc., to achieve the effects of large axial peeling force, good insulation performance, rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation process of the above-mentioned reinforcement ring structure comprises the following steps:

[0037] 1) Configure insulating layer coating material: the coating material includes the following raw materials in parts by weight: 3-5 parts of polyester resin, 1.5-2.5 parts of polyester imide resin, 0.8-1.2 parts of polyurethane, 0.8-1.2 parts of epoxy resin 0.1 to 0.5 parts of curing agent and 1 to 1.5 parts of diluent, wherein the curing agent is a modified hydrazide latent curing agent, including hydrazide compounds and epoxy compounds, wherein the molar ratio of hydrazide groups to epoxy groups It is 1:0.5-2.5, and the diluent is set to active epoxy resin diluent.

[0038]2) Stretching, blanking and cutting of seamless steel pipes inside and outside: use broaching equipment to position the 65Mn seamless steel pipes with an inner diameter of 47.8-47.9mm and a thickness of 1.2-1.35mm, and then use broaching equipment to position the two ends of the seamless...

Embodiment 1

[0045] The preparation process of the reinforcement ring structure is as follows:

[0046] 1) Prepare insulating layer coating material: mix 3 parts of polyester resin, 2 parts of polyester imide resin, 1 part of polyurethane, 1 part of epoxy resin, 0.25 part of curing agent and 1 part of thinner to obtain the coating material.

[0047] 2) Stretching, blanking and cutting of seamless steel pipes inside and outside cold work: use broaching equipment to position the 65Mn seamless steel pipes with an inner diameter of 47.8-47.9mm and a thickness of 1.2-1.35mm, and then perform cold work inside and outside Stretching, the tensile force is 10000N, the tensile speed is 80mm / Min, the stretching time is 40-60 minutes, after stretching to an inner diameter of 48.0-48.05mm and a thickness of 1.0-1.05mm, the material is cut into multiple pieces 500mm steel pipe section.

[0048] 3) Heat treatment of the cut steel pipe section: heat the cut steel pipe section to 820-840°C, cool it in oil...

Embodiment 2

[0055] The difference between the preparation process of the reinforcing ring structure and that of Example 1 lies in the proportioning of the coating materials, that is, 4 parts of polyester resin, 2 parts of polyester imide resin, 1 part of polyurethane, 1 part of epoxy resin, and 0.25 parts of curing agent Mix with 1 part thinner to obtain coating material. Coat the inner wall of the steel pipe section with the coating material in the above ratio until the thickness reaches 2.5 mm, and put the steel pipe section coated with the coating material into a drying oven at a temperature of 125-145 ° C for 30-45 minutes; The required reinforcement ring is obtained after post-processing the steel pipe section.

[0056] After passing the performance test, it is obtained that the radial destructive force that the above-mentioned reinforcement ring can withstand is 2800N, the insulation performance is a withstand voltage of 3350V, the withstand temperature is 275°C, and the axial peeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com