Method for improving exposure uniformity of PCB

A technology of PCB board and uniformity, applied in the field of improving the exposure uniformity of PCB board, can solve the problems of over-exposure or false exposure, affecting product quality, uneven board thickness, etc., and achieve the effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

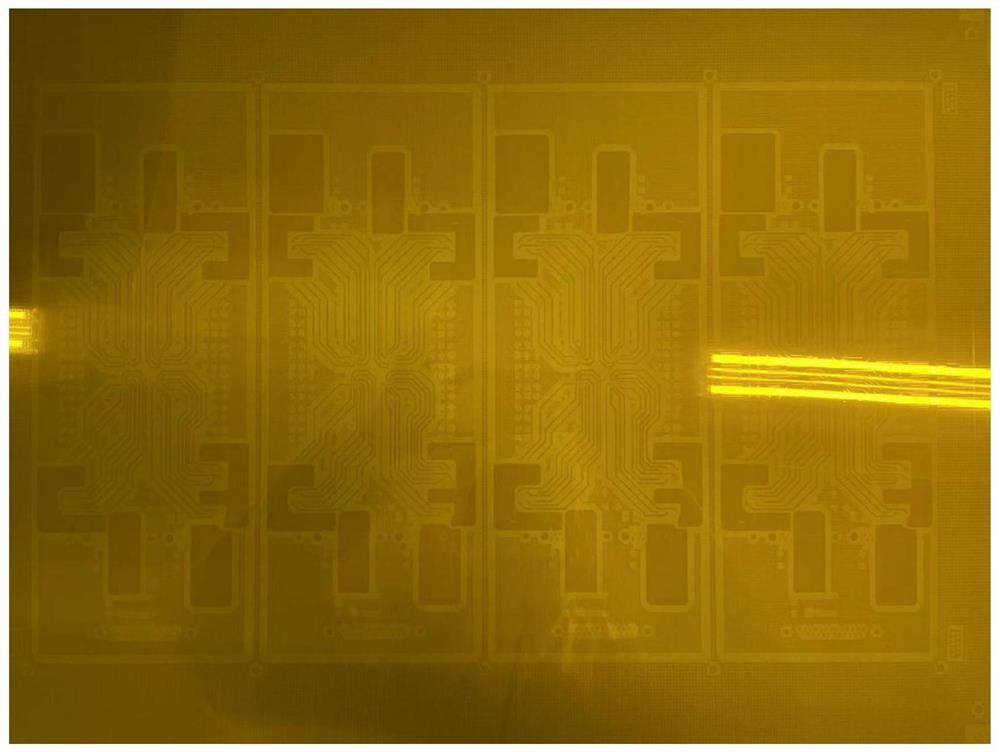

[0027] Taking a product A as an example, the theoretical design thickness of this product is 210mil, the size is 18*24inch, the tolerance control of the customer's board thickness is + / -7%, and the control of the residual copper in deep drilling is 2-10mil. This product operates a total of 6WPNL , the thickness of the board is measured after lamination and milling.

[0028] Put this board into the measuring table one by one, use the chuck to clamp the product, start the equipment and start working, the set measuring grid is 1*1mm, the thickness of the entire board needs to be measured, and this measurement is based on the configuration of the equipment. 278,709 points are required to complete the coverage of the entire surface. The measurement speed of the equipment is 500 times / s, so the measurement time of the entire board surface is 9 minutes. The specific steps are as follows:

[0029] 1. After the PCB to be tested is fixed by the fixture, the laser Mark head starts first,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com