Preparation method of GaN-based LED chip with performance optimization effect

A LED chip and performance technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy formation of open circuit, metal interconnection fracture, short circuit, etc., to reduce leakage current, improve reliability, and optimize transportation characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Taking a high-voltage LED chip as an example, a preparation method for optimizing the performance of a GaN-based LED chip is characterized in that it includes the following steps:

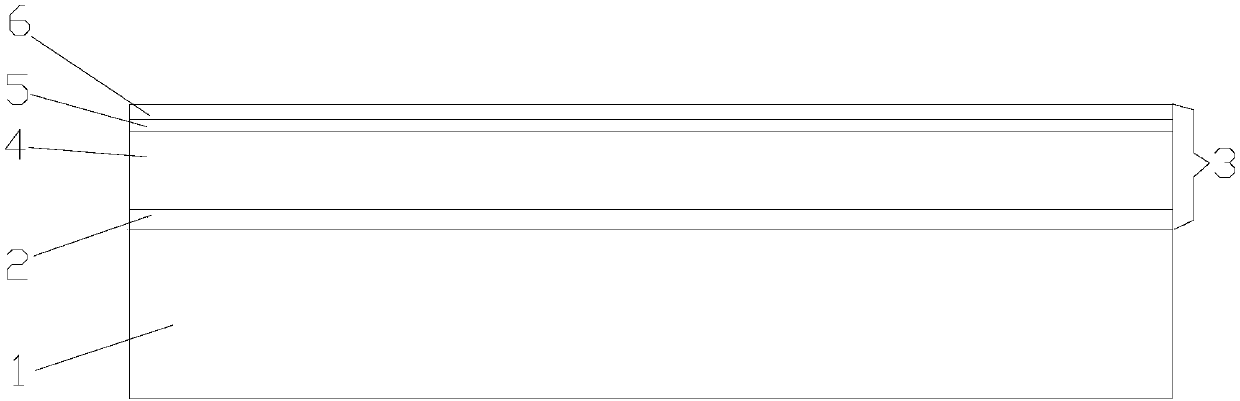

[0039] Such as figure 1 As shown, step 1. Fabricate the epitaxial layer: provide a substrate 1, grow buffer layer 2, N-GaN layer 4, multiple quantum wells 5, P-GaN layer 6 sequentially on the substrate 1, and complete GaN-based epitaxy The production of layer 3;

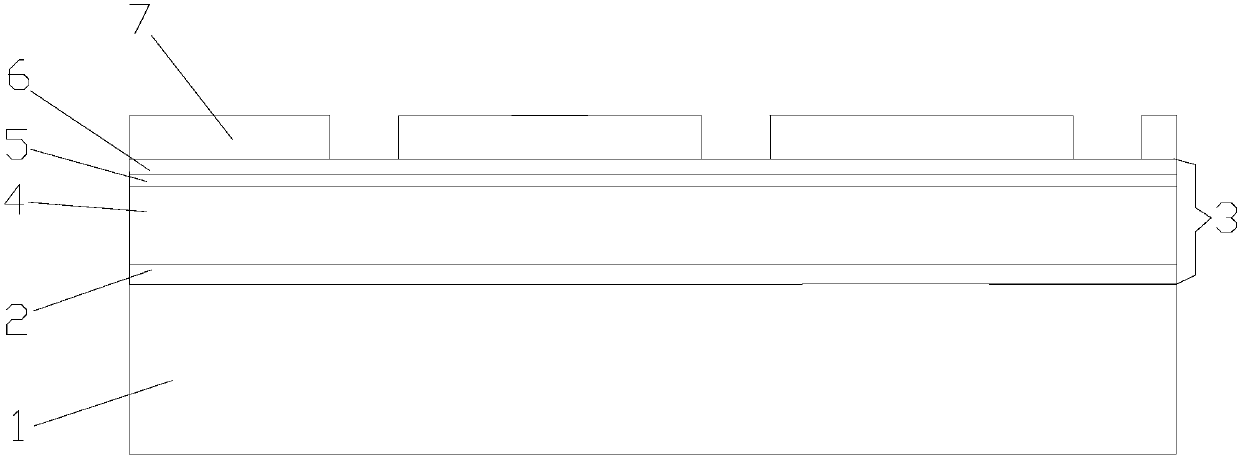

[0040] Such as figure 2 As shown, step 2. Fabricate the transparent conductive layer 7: use electron beam evaporation or magnetron sputtering technology to evaporate ITO on the upper surface of the GaN epitaxial layer 3, and use HCl solution to process the ITO through the shielding of the patterned photoresist. Etching to form a transparent conductive layer 7;

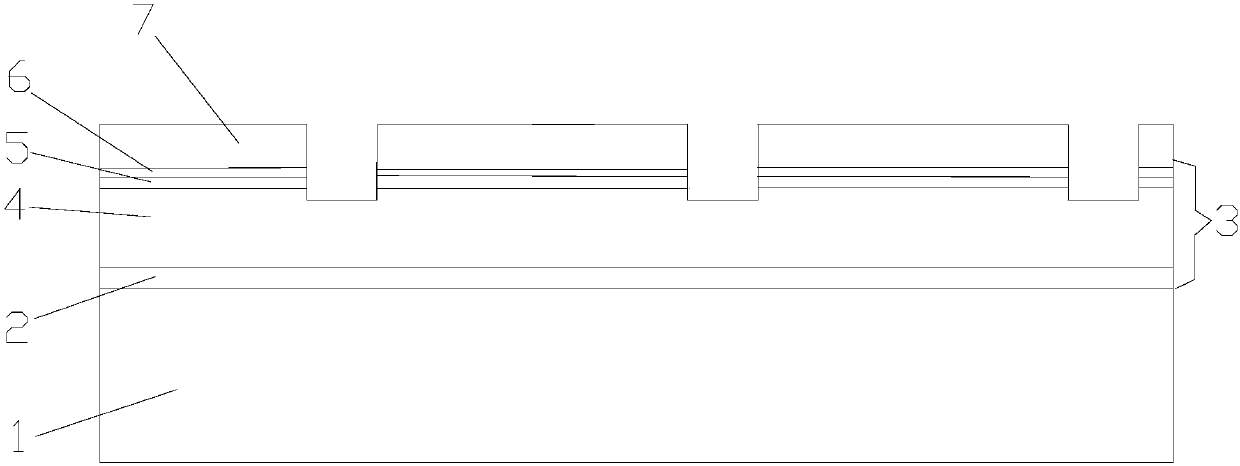

[0041] Such as image 3 As shown, step 3. Forming the N-electrode lead-out hole: under the cover of the patterned photoresist, continue to dry-etch the P...

Embodiment 2

[0049] Embodiment 2 Taking a flip-chip LED chip as an example, a preparation method for optimizing the performance of a GaN-based LED chip is characterized in that it includes the following steps:

[0050] Such as figure 1 As shown, step 1. Fabricate the epitaxial layer: provide a substrate 1, grow buffer layer 2, N-GaN layer 4, multiple quantum wells 5, P-GaN layer 6 sequentially on the substrate 1, and complete GaN-based epitaxy The production of layer 3;

[0051] Such as Figure 7 As shown, step 2. Fabricate the transparent conductive layer 7: use electron beam evaporation or magnetron sputtering technology to evaporate ITO on the upper surface of the GaN epitaxial layer 3, and use HCl solution to process the ITO through the shielding of the patterned photoresist. Etching to form a transparent conductive layer 7;

[0052] Such as Figure 8 As shown, step 3. Forming the N-electrode lead-out hole: under the cover of the patterned photoresist, continue to dry-etch the P-G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com