Method for processing high-concentration chlorine-containing wastewater

A high-concentration, waste water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of no recovery of metal zinc and hydrochloric acid, increased production cost of indium extraction, industrial waste water Deal with problems such as system troubles, achieve the effect of solving chloride ion balance and open circuit, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

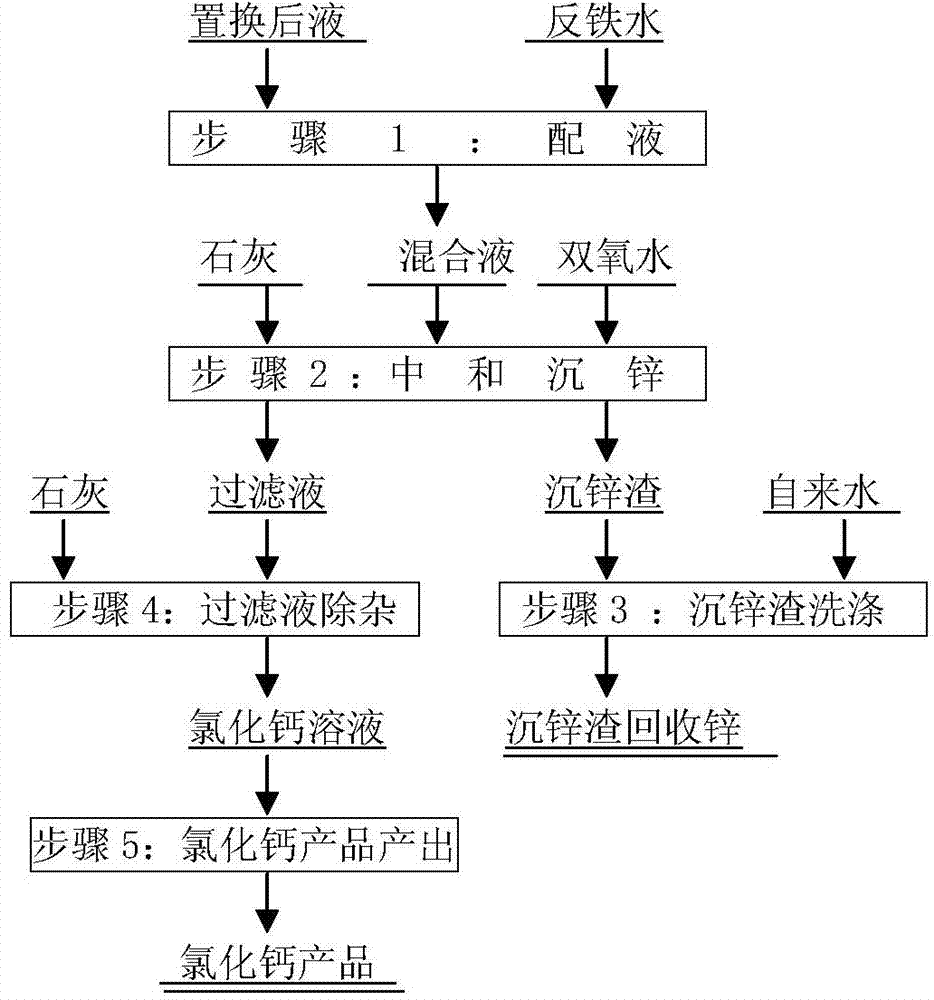

Method used

Image

Examples

no. 1 example

[0017] This embodiment is the first example of the method for treating high-concentration chlorine-containing wastewater according to the present invention, comprising the following steps:

[0018] (1) Dosing: 10m of replacement solution containing 200g / L zinc, 5g / L iron and 225g / L chlorine 3 And 10m of molten iron containing 180g / L hydrochloric acid and 15g / L iron 3 , in a volume of 30m 3 The mixing tank is mixed and prepared to obtain 20m of zinc chloride acidic mixture containing 100g / L of zinc, 2.5g / L of iron and 90g / L of hydrochloric acid. 3 ;

[0019] (2) Neutralization of zinc precipitation: at a reaction temperature of 60°C, at 20m 3 Add lime 4450 kg and hydrogen peroxide 0.76m in the mixed solution 3 Carry out zinc precipitation, zinc precipitation reaction is 3 hours, then filter, obtain 43% of water content, 6.8 tons of wet state zinc precipitation slag containing 51% of zinc and filtrate 17.2m 3 ;

[0020] (3) Zinc slag washing: at room temperature, wash the ...

no. 2 example

[0024] This embodiment is the second example of the method for treating high-concentration chlorine-containing wastewater according to the present invention, comprising the following steps:

[0025] (1) Dosing: 12m of replacement solution containing 200g / L zinc, 5g / L iron and 225g / L chlorine 3 And 10m of molten iron containing 180g / L hydrochloric acid and 15g / L iron 3 , in a volume of 30m 3 The mixing tank is mixed and prepared to obtain 22m of zinc chloride acidic mixed solution containing 109g / L of zinc, 2.7g / L of iron and 82g / L of hydrochloric acid. 3 ;

[0026] (2) Neutralizing zinc precipitation: under the condition of reaction temperature of 65°C, at 22m 3 Add 5075 kg of lime and 0.86m of hydrogen peroxide to the mixed solution 3 Carry out zinc precipitation, zinc precipitation reaction is 3 hours, then filter to obtain 8.7 tons of wet state zinc precipitation slag with 45% water content and 50% zinc content and 18.8m of filtrate 3 ;

[0027] (3) Zinc slag washing:...

no. 3 example

[0031] This embodiment is a third example of a method for treating high-concentration chlorine-containing wastewater according to the present invention, including the following steps:

[0032] (1) Dosing: 15m of replacement solution containing 200g / L zinc, 5g / L iron and 225g / L chlorine 3 And 10m of molten iron containing 180g / L hydrochloric acid and 15g / L iron 3 , in a volume of 30m 3 The mixing tank is used for mixing and dosing to obtain 25m of zinc chloride acidic mixed solution containing 120g / L of zinc, 3g / L of iron and 72g / L of hydrochloric acid 3 ;

[0033] (2) Neutralizing zinc precipitation: under the condition of reaction temperature 70℃, at 25m 3 Add 5870 kg of lime and 1.0m of hydrogen peroxide to the mixture 3 Carry out zinc precipitation, zinc precipitation reaction is 3 hours, filter then, obtain the wet state zinc precipitation slag 10.9 tons of water content 44%, zinc content 49% and filtrate 20.9m 3 ;

[0034] (3) Zinc slag washing: at room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com