Automotive acoustic damping component and production method and application thereof

An automobile and damping technology, applied in vehicle parts, chemical instruments and methods, transportation and packaging, etc., can solve the problems of indoor air pollution in automobiles, easy sleepiness of drivers and occupants, and air quality pollution in vehicles, so as to reduce traffic accidents. , The ability to fill the cavity is strong, the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

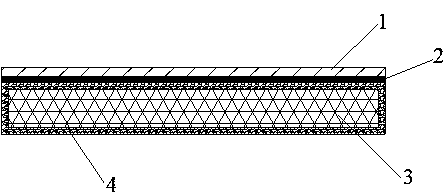

[0031] A sound-absorbing, damping and shock-absorbing component of an automobile, comprising: an isolation and anti-adhesive layer 1, an adhesive damping layer 2, a flame-retardant sound-absorbing cotton layer 3 and a microporous sound-absorbing film coating layer 4, and its preparation method specifically includes the following steps:

[0032] The selected flame-retardant and sound-absorbing cotton is blanked, and the shape of the flame-retardant and sound-absorbing cotton is die-cut according to the shape of the auto parts, and the die-cut flame-retardant and sound-absorbing cotton layer 3 is covered with a microporous sound-absorbing film, and then the microporous sound-absorbing film layer 4 is ultrasonically Die-cut parts are welded and hot-pressed at a temperature of 180°C~330°C. The die-cut parts are punched, the die-cut parts are honed, and the bonding surface of the die-cut parts and auto parts is coated with an adhesive damping layer 2, and finally compounded and isola...

Embodiment 2

[0034] A sound-absorbing, damping and shock-absorbing component of an automobile, comprising: an isolation and anti-adhesive layer 1, an adhesive damping layer 2, a flame-retardant sound-absorbing cotton layer 3 and a microporous sound-absorbing film coating layer 4, and its preparation method specifically includes the following steps:

[0035] The selected flame-retardant and sound-absorbing cotton is blanked, and the shape of the flame-retardant and sound-absorbing cotton is die-cut according to the shape of the automobile parts, and the die-cut flame-retardant and sound-absorbing cotton layer 3 is covered with a microporous sound-absorbing film, and then the microporous sound-absorbing film layer 4 is heated Die-cut parts are made of heat-pressed edge banding at a temperature of 180 ° C ~ 330 ° C. Die-cut parts are punched, die-cut parts are honed, and adhesive damping layer 2 is applied to the joint surface of die-cut parts and auto parts. Adhesive layer 1, inspection, pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com