A fast folding anti-collision type electric vehicle bumper assembly

An electric vehicle, foldable technology, applied in the direction of the bumper, etc., can solve the problems of short driving range and long charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

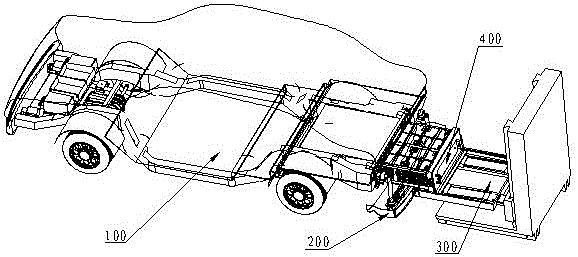

[0016] Describe the specific implementation below, figure 1 It is a quick-change schematic diagram of the battery module of a fast-folding anti-collision type electric vehicle bumper assembly in this case, 100 in the figure is an electric car, and 200 in the figure is a fast-folding anti-collision type electric vehicle bumper assembly described in this case , 300 in the figure is a device for quickly changing battery modules. It can be clearly seen from the figure that the bumper assembly described in this case is pulled out and folded and turned downward by 90 degrees, which provides a channel for the battery module to be pulled out.

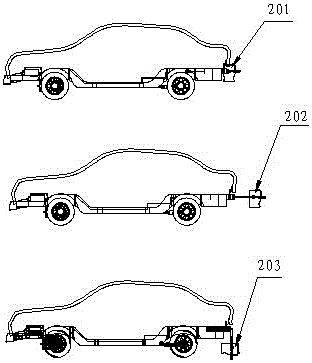

[0017] figure 2 It is a schematic diagram of three working positions of a quick-folding anti-collision electric vehicle bumper assembly in this case, 201 in the figure is the initial position of the bumper assembly in this case, and 202 in the figure is the bumper assembly in this case The pull-out position of the bumper assembly in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com