Mechanical self-locking device of TKH series change-over switch

A transfer switch and self-locking device technology, which is applied to locomotives and other directions, can solve problems such as air leakage from the working air pressure cylinder, transfer switch cannot maintain normal working status, and use is dangerous, so as to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

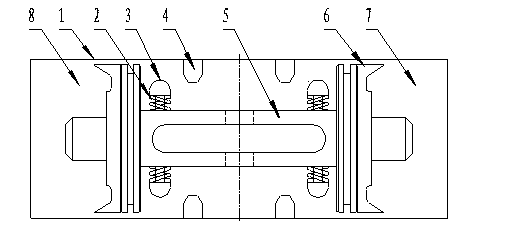

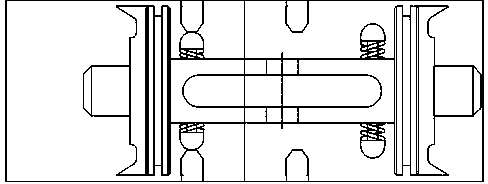

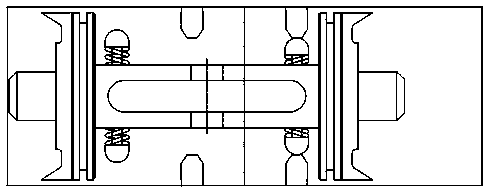

[0014] Embodiment 1: A mechanical self-locking device for a TKH series changeover switch, including a cylinder body 1 and a piston rod 5. The piston rod 5 is respectively provided with two sliders connected by a slider spring 2 at a distance from each other on the upper and lower sides of the piston rod 5. 3. Two static contacts 4 are respectively arranged on the upper and lower inner walls of the cylinder body 1 to correspond between two adjacent sliders 3 .

[0015] The sum of the length of the slider spring 2 when it is compressed by the gravity of the slider 3 , the length of the slider 3 and the length of the static contact 4 is greater than the distance between the inner wall of the cylinder body 1 and the surface of the piston rod 5 . Only such length setting can make the piston rod 5 move left and right, there is contact between the slider 3 and the static contact 4, and the effect of locking is played.

Embodiment 2

[0016] Embodiment 2: as figure 1 As shown, a TKH series transfer switch mechanical self-locking device includes a cylinder body 1 and a piston rod 5. The piston rod 5 is respectively provided with two sliders 3 connected by a slider spring 2 at a distance from each other on the upper and lower sides of the piston rod 5. , the upper and lower inner walls of the cylinder body 1 are respectively provided with two static contacts 4 corresponding between two adjacent sliders 3, the length of the slider spring 2 when it is compressed by the gravity of the slider 3, and the length of the slider 3 And the sum of the lengths of the static contact 4 is greater than the distance between the inner wall of the cylinder body 1 and the surface of the piston rod 5 .

[0017] The slider spring 2 is sleeved on a rod vertically and fixedly connected to the surface of the piston rod 5, and the slider 3 is movably sleeved on the upper part of the rod.

[0018] The end of the static contact 4 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com