Bit packing tube with positioning

A technology for packaging tubes and drill bits, which is applied in packaging, internal accessories, etc., and can solve the problems of packaging aesthetics, blurred vision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

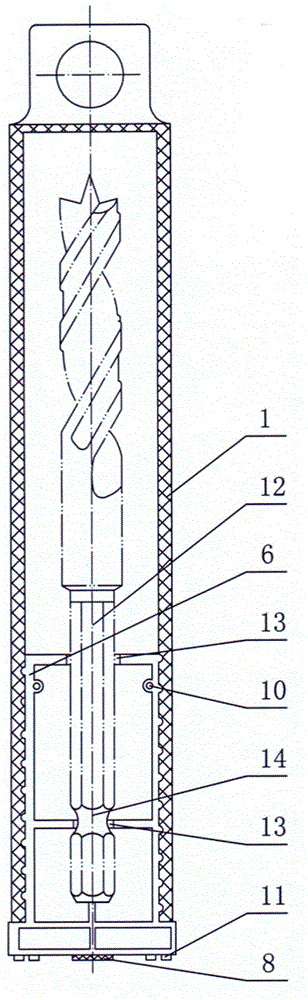

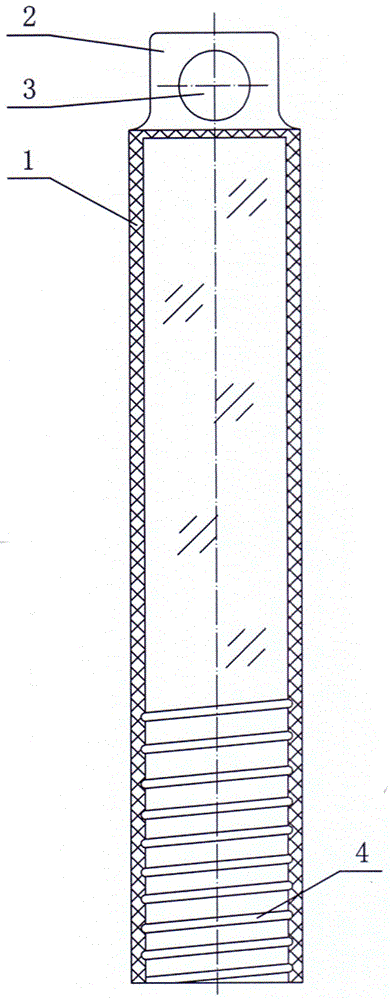

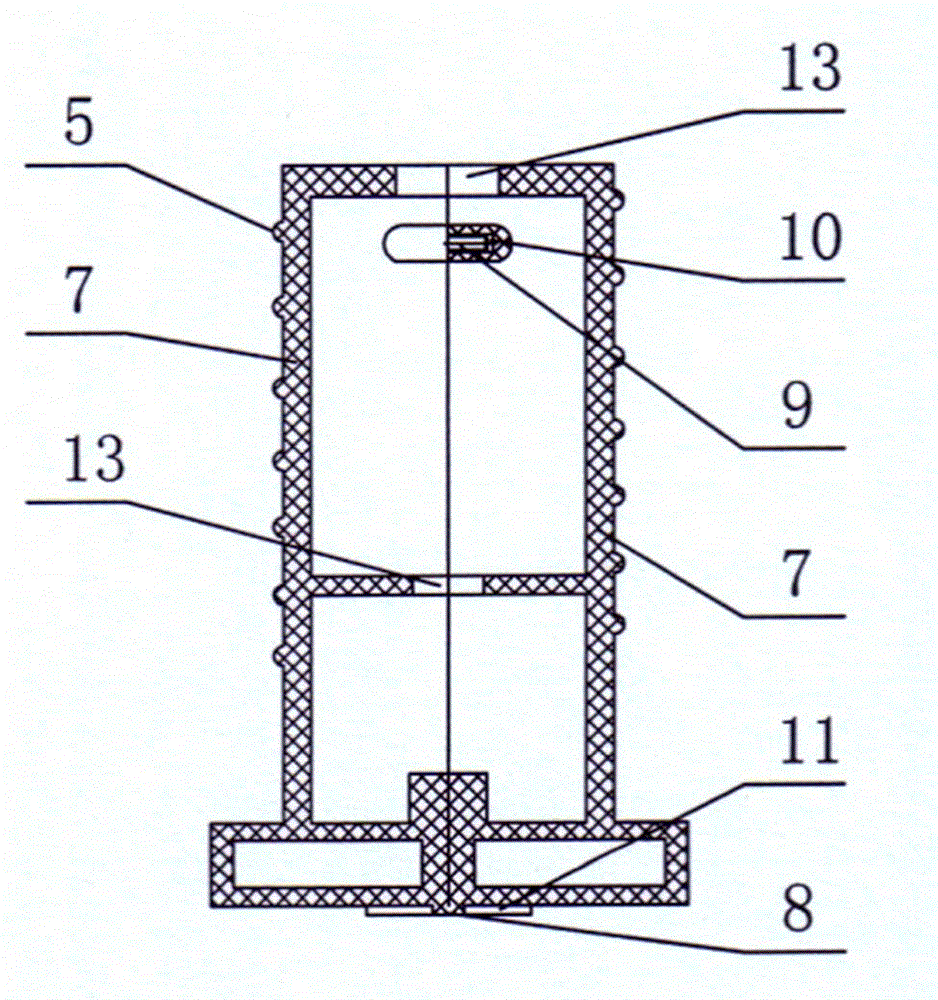

[0020] figure 1 It is a state diagram of a drill bit installed in the packaging casing with positioning, as seen from the figure, it includes a transparent plastic pipe body 1 such as figure 2 As shown, the top of the pipe body 1 is provided with a connecting piece 2, and the connecting piece 2 is formed with a through hole 3 for hooking. The mouth of the pipe body is shaped on a screw hole 4, and the screw hole 4 is screwed with a cap 6 matching the thread 5 of the screw hole 4 such as Figure 3 to Figure 6 Shown, described cap 6 is formed by the combination of two halves of half caps 7, and these two halves of caps 7 connect them to each other at their bottoms through cap connecting bands 8. together as Figure 6 shown. Pins 9 and jacks 10 that are inserted into each other are respectively formed on the mating surfaces of the two halves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com