Automatic bar member feeding mechanism

A technology of automatic feeding and parts, which is applied in the direction of conveyor, transportation and packaging, etc., and can solve the problem of uncontrollable rolling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

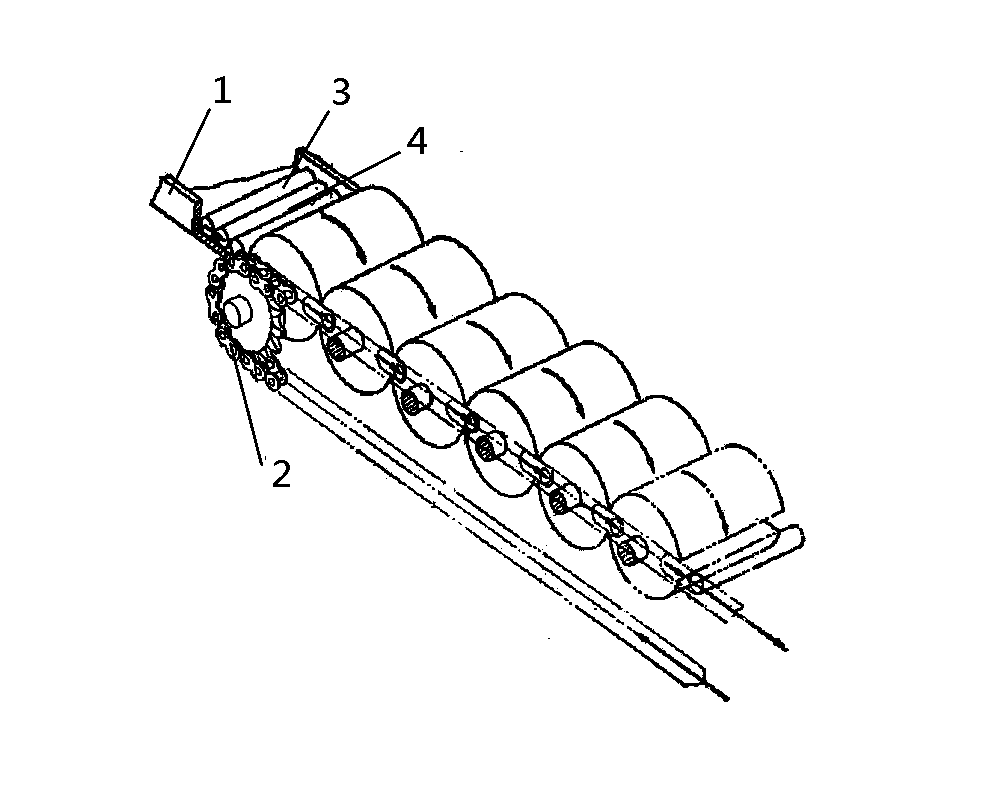

[0011] like figure 1 As shown: it includes the conveying channel 1 for placing bar pieces and the driving sprocket 2 for driving the conveying channel. The conveying channel 1 is inclined towards the direction of the processing station. The conveying channel 1 is composed of a plurality of parallel conveying rods 3. The conveying rod 3 is a slender cylindrical structure, and a groove 4 for placing workpieces is formed between two adjacent conveying rods 3. The width of the groove 4 is greater than the radius of the bar material and smaller than the diameter of the bar material. The length of the conveying rod 3 and the conveying distance Bar stock pieces are the same length.

[0012] When working, use the conveying channel 1 to store the bar material, and form a groove 4 for placing the workpiece between two adjacent conveying rods 3. The width of the groove 4 is greater than the radius of the bar material and smaller than the diameter of the bar material, so that each bar Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com