Cranked link chain

A technology of bending plate chain and chain link, applied in the field of bending plate chain, can solve the problems of production accident, broken chain link, easy falling off of the pin shaft, etc., to increase the service life, reduce the occurrence of accidents, and prevent the pin shaft from moving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

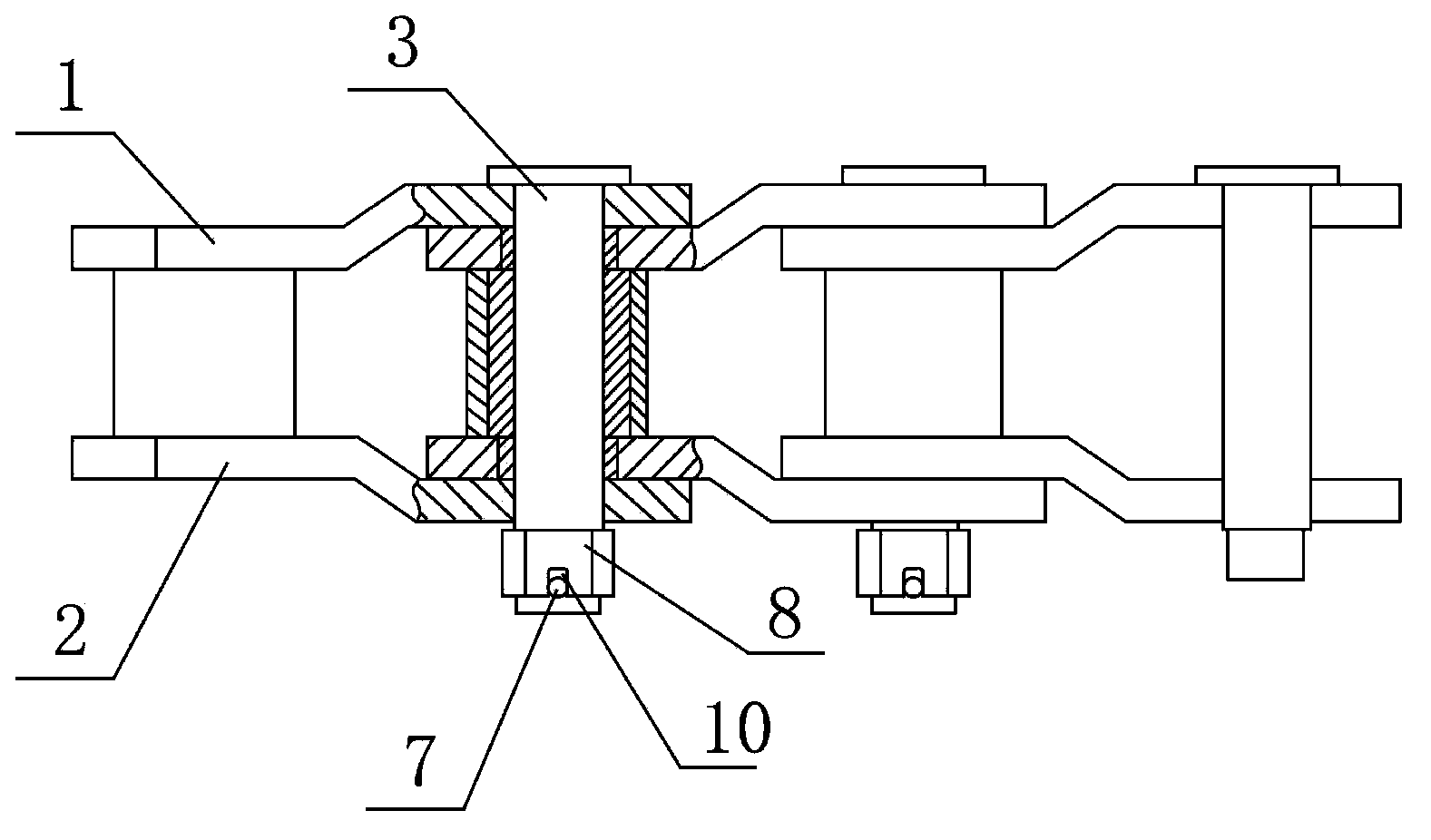

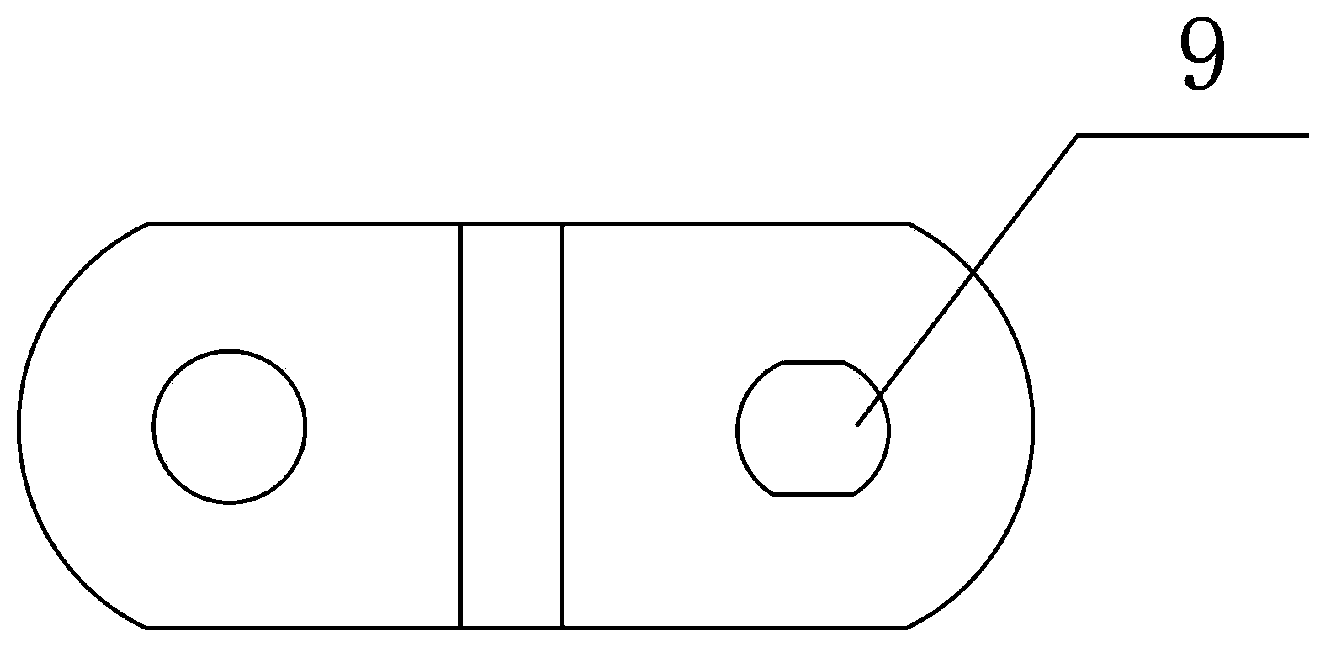

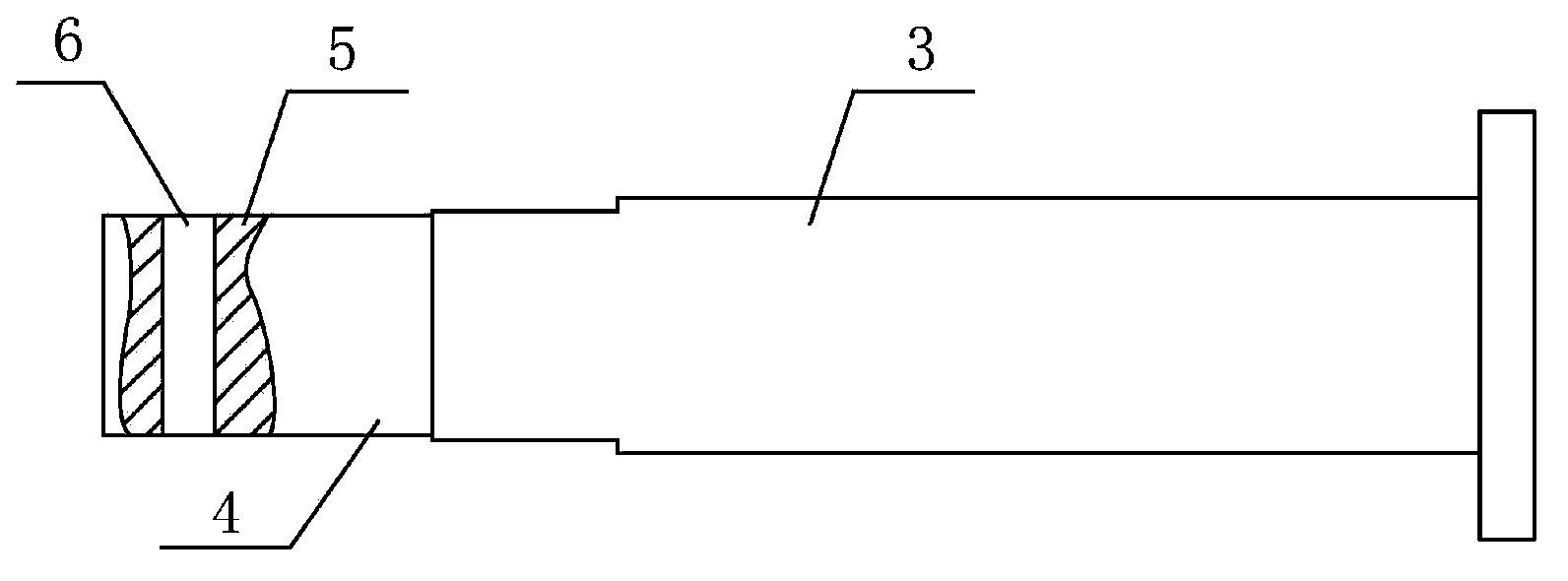

[0010] The present invention will be further explained below in conjunction with accompanying drawing. like figure 1 , figure 2 , image 3 Middle, 1-link A, 2-link B, 3-pin shaft, 4-long flat, 5-thread, 6-cotter pin hole, 7-cotter pin, 8-lock nut, 9-long hole, 10-way slot.

[0011] The chain link A1 and the chain link B2 are connected by the pin shaft 3, the locking end of the pin shaft 3 is provided with a cotter pin hole 6, the locking end of the pin shaft 3 is provided with a long flat 4 and a thread 5, and the long flat 4 runs through the chain link B2 The corresponding elongated hole 9 is provided on the top, and is fixedly connected with the lock nut 8 through the thread 5, and the lock nut 8 is provided with a through groove 10 connected with the cotter pin hole 6, and the cotter pin 7 runs through the through groove 10 And cotter pin hole 6.

[0012] The usage examples of the present invention have been described above in detail, but the content described is only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com