Mechanical arm type ball outlet conveyor of steel ball eddy current flaw detector

An eddy current flaw detection and conveyor technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve problems that affect product quality, time-consuming and labor-intensive, and steel ball surface damage, and achieve the goal of improving yield and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

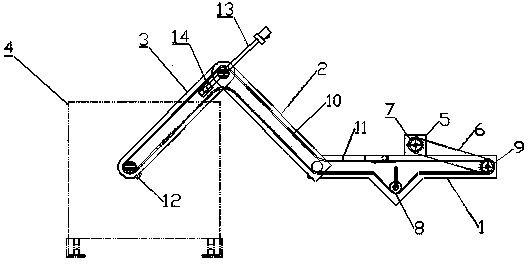

[0013] like figure 1 The shown one kind of steel ball eddy current flaw detector mechanical arm type ball discharge conveyor is a three-stage conveyor, and the three sections are the head horizontal conveying section 1, the middle conveying section 2 and the tail adjustable conveying section 3, and the three sections are respectively There is a hinged connection between them, and a turnover box 4 is placed at the lower end of the tail of the ball discharge conveyor;

[0014] The ball conveyor includes a speed-regulating motor 5, a transmission belt 6, a power wheel 7, a pressing wheel 8, a driven wheel 9 and a conveyor belt 10; the rotating shaft of the speed-regulating motor is connected to the power wheel 7; Connect and drive the driven wheel 9 to rotate; the driven wheel 9 drives the conveyor belt 10 to work, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com