Cooperative type main turning pincer structure

A lock tongue and movable plate technology, applied in the field of flip clamp structure, can solve the problems of difficult welding, heavy weight, and inability to adapt to the lifting environment, and achieve the effects of improving lifting efficiency, high flexibility, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

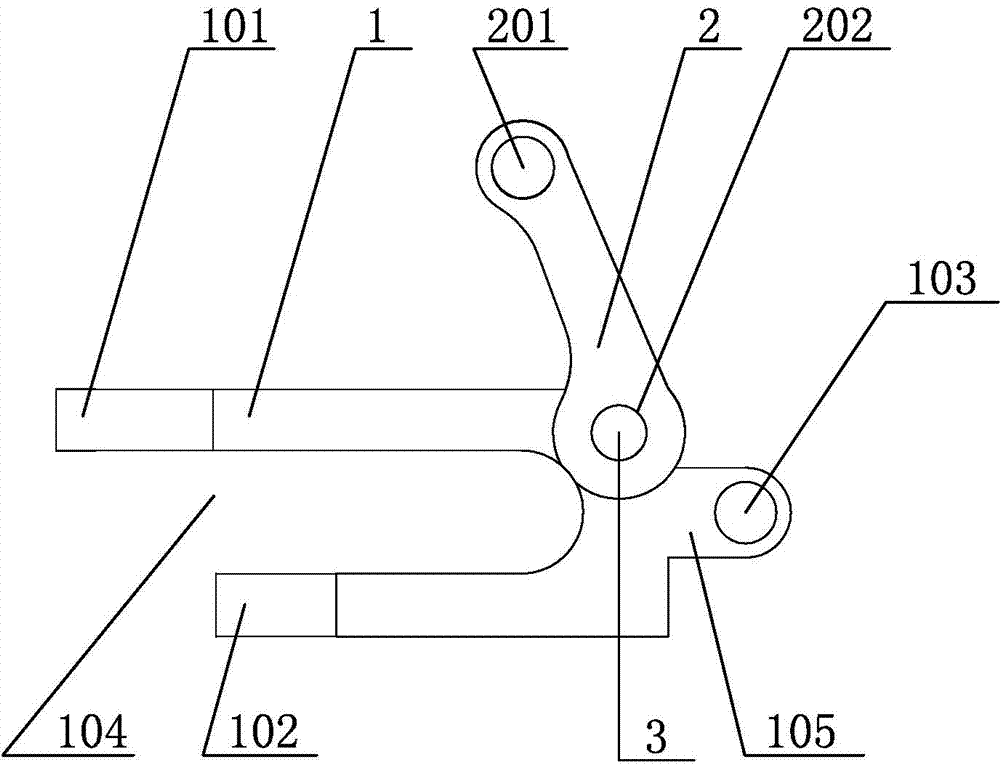

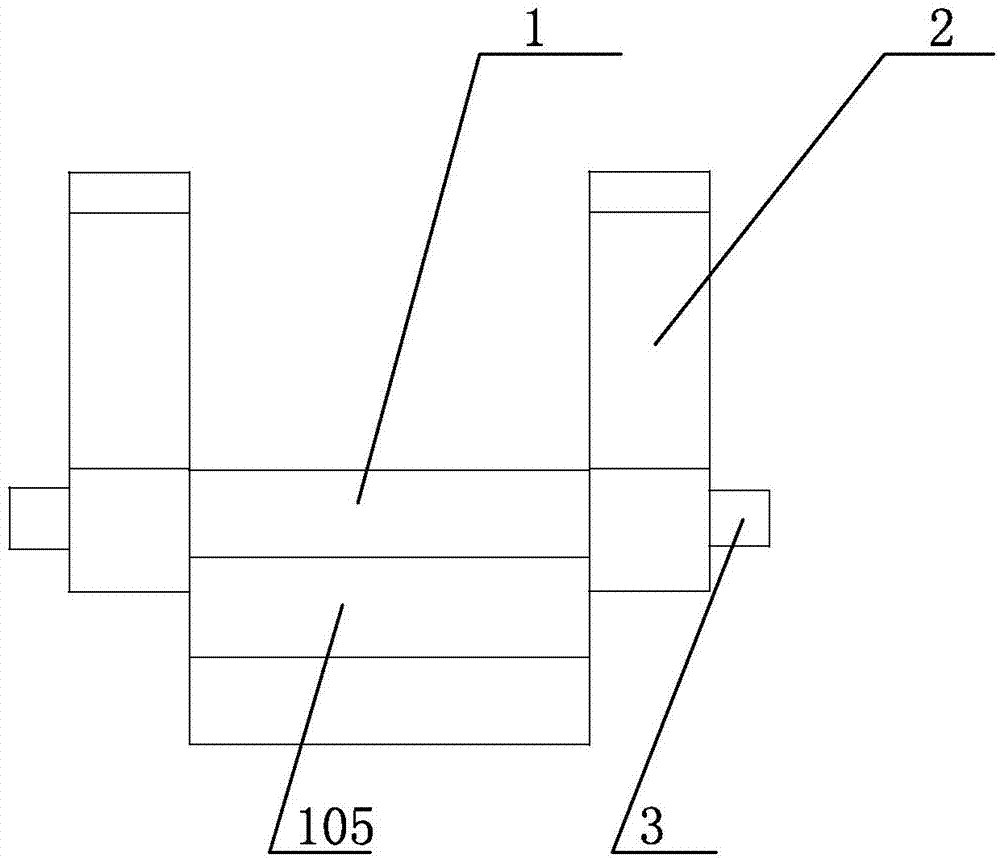

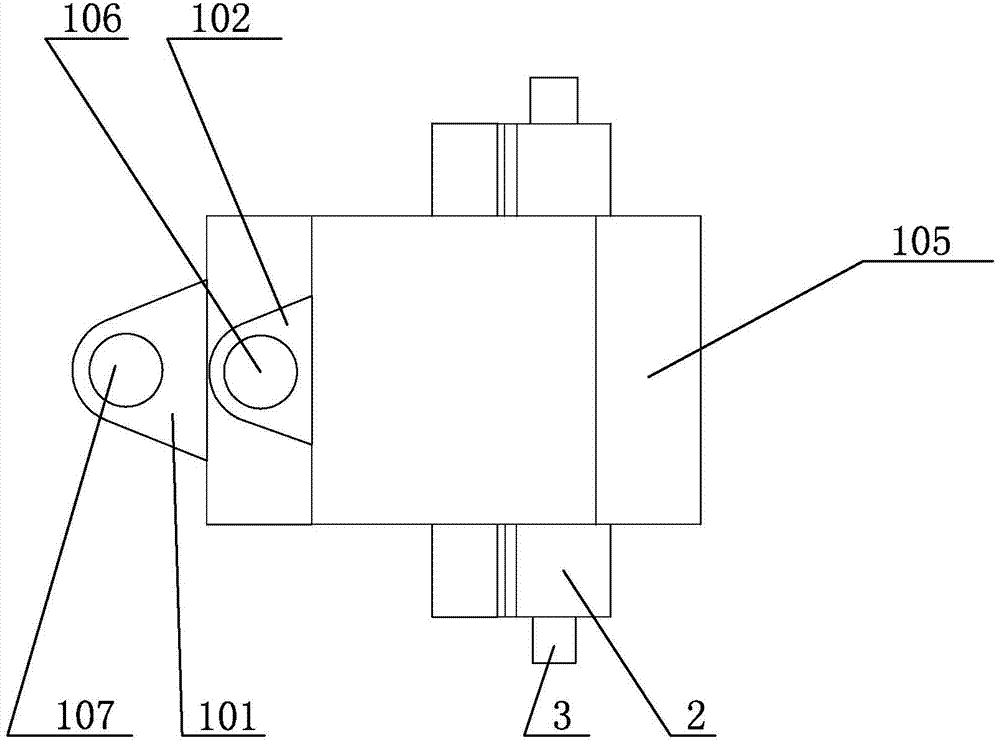

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0019] like Figure 1 to Figure 3 As shown in the figure, a cooperative main flipping pliers structure includes a pliers tongue 1, which is located on both sides of the pliers tongue 1 and is hinged with a movable plate 2 through a rotating pin 3 respectively. One end of the pliers tongue 1 bends and extends along the other end to form a "U". Shaped opening 104, one end of movable plate 2 has hoisting hole 201, and the other end has rotation pin installation hole 202. One end of the pliers tongue 1 is extended to form a first lock tongue 101, the other end of the pliers tongue 1 is extended to form a second lock tongue 102, and the curved part of the pliers tongue 1 also extends outward to form a boss 105, and the boss 105 opens inwardly. There are through holes 103 . The length of the clamp tongue 1 with the first lock tongue 101 is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com