Moving arm tower crane installation method

An installation method and the technology of the luffing jib tower crane are applied in the direction of cranes, etc., which can solve the problems of high cost, large amount of operation, and low efficiency, and achieve the effects of saving time and cost, reducing work risk, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

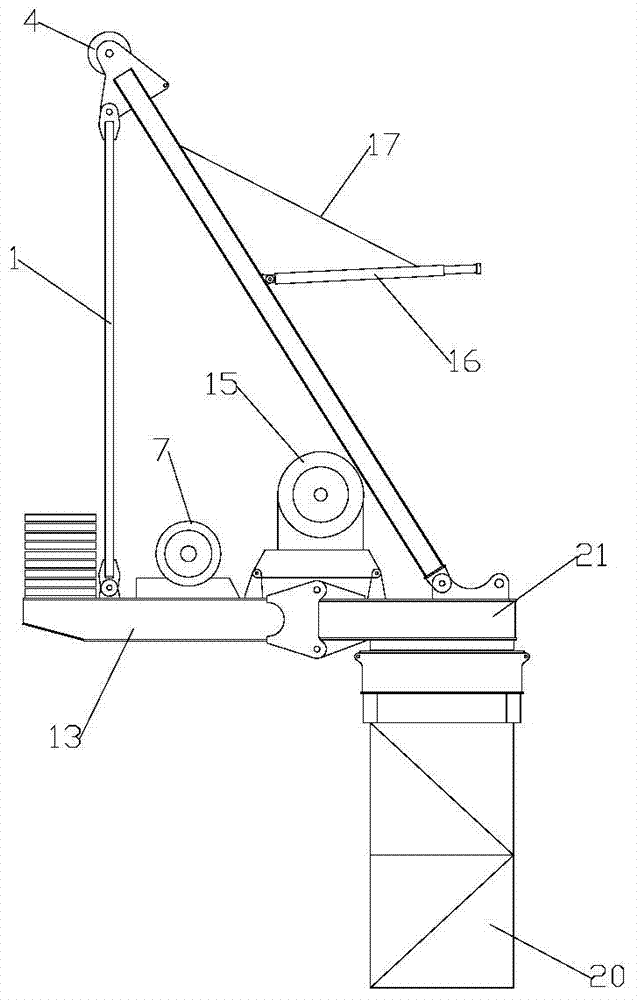

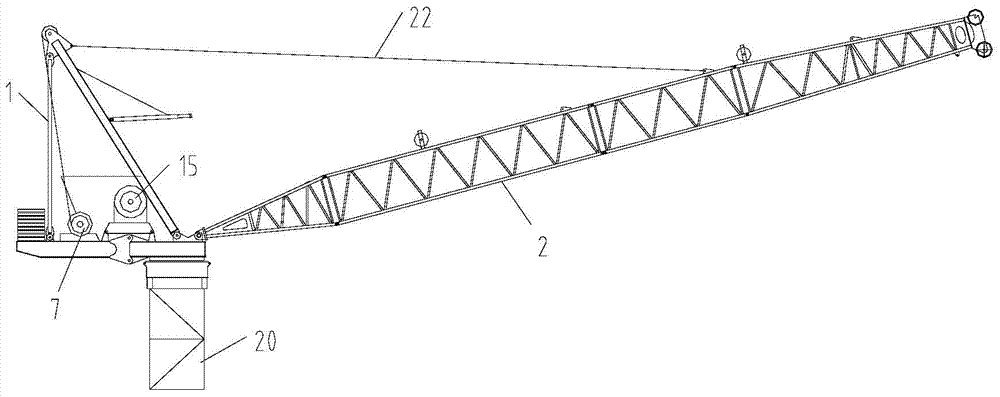

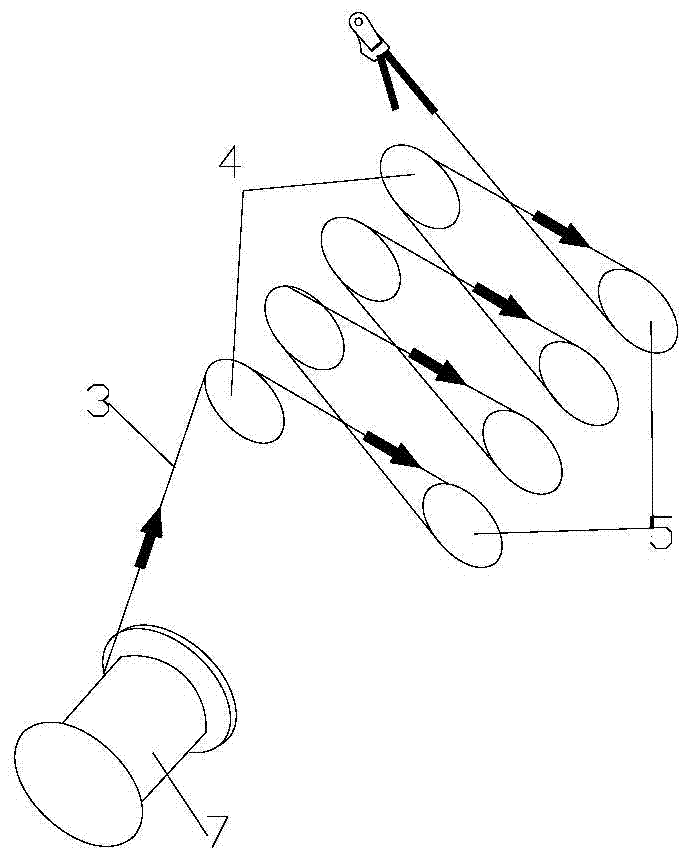

[0037] Please refer to Figure 6 to Figure 12 , the present invention provides a method for installing a luffing jib tower crane, comprising: fixing the A-frame 1 and the jib 2 into a combined body; The state is pre-assembled on the combination; hoist the combination to the upper support 6, and pivotally connect the front strut 18 of the A-frame 1 and the arm root of the boom 2 to the upper support 6; The connection between the A-frame 1 and the boom 2; using the luffing mechanism 7 to turn the A-frame 1 to a normal installation state; installing the A-frame 1.

[0038] In the process of installation, the present invention first completes the installation of the tower body and other lower parts as in the prior art. Then, refer to Image 6 , the A-frame 1 and the boom 2 will be pre-fixed and assembled together on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com