Multifunctional roll mounting device

An installation device and multi-functional technology, which is applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problem of increasing the work risk of operators, the difficulty of improving the work efficiency of the production line, and the high and low assembly accuracy requirements of the height adjustment parts. advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

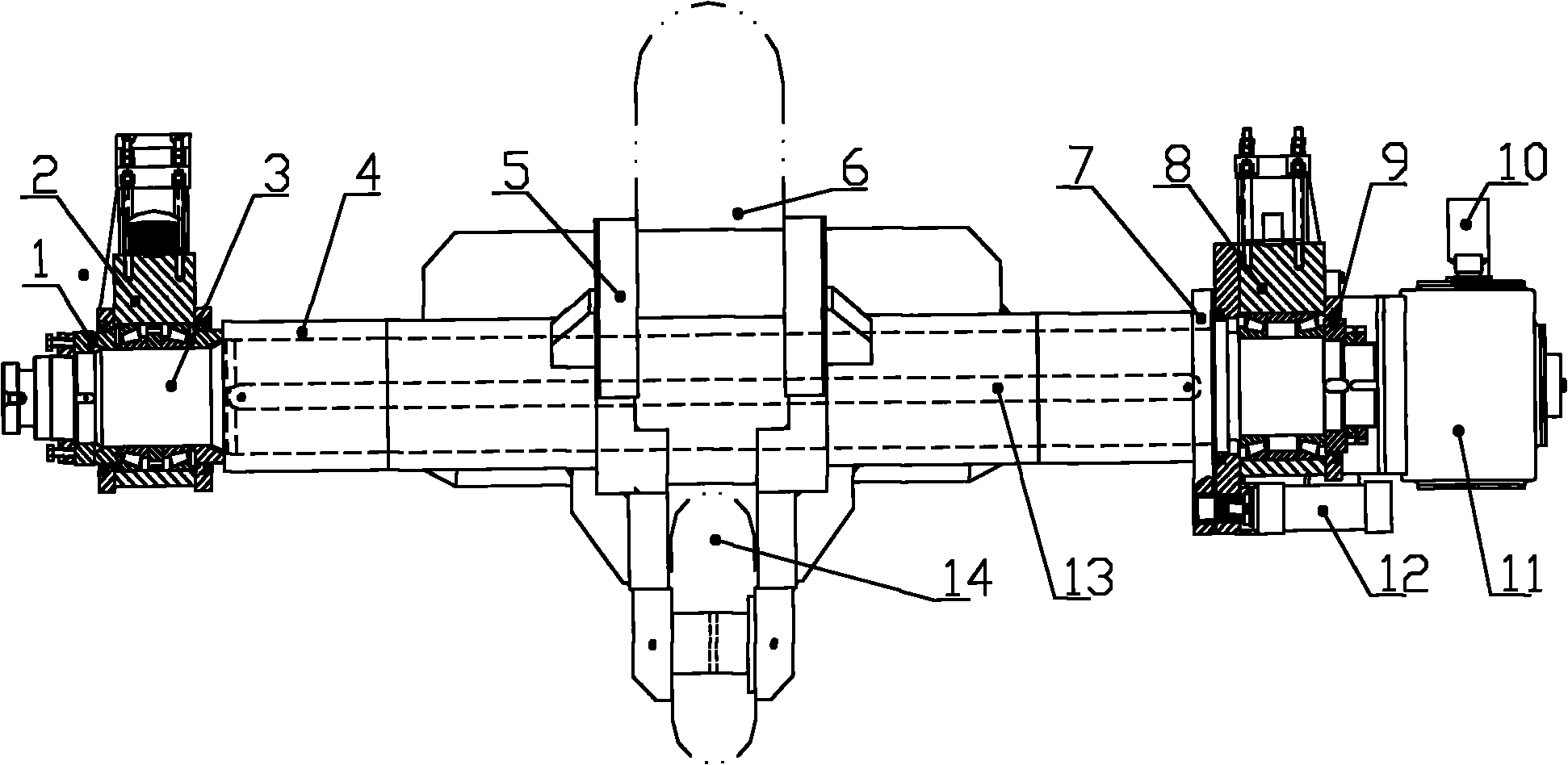

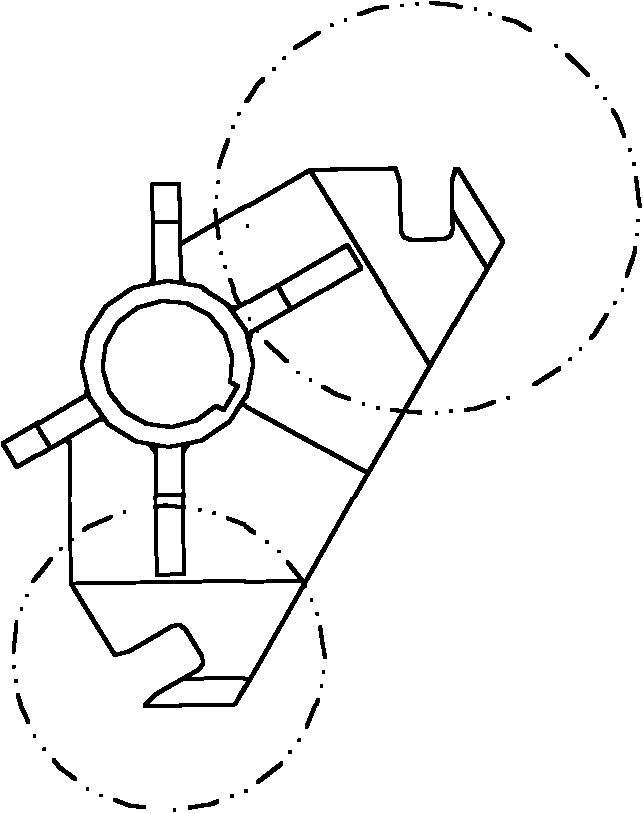

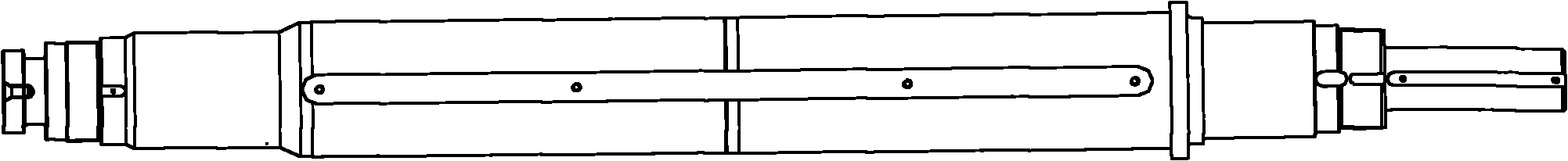

[0028] See figure 1 , the present invention is a multi-functional roll installation device, including a fixed shaft 3 with a key 13, a support seat 5, a positioning sleeve 7, an oil cylinder 12, and a driving part installed on the fixed shaft 3. The two parts of the fixed shaft 3 The left bearing seat 2 and the right bearing seat 8 are respectively provided at the end, the support seat 5 and the positioning sleeve 7 are installed on the fixed shaft 3 through the key 13, the roll is installed on the support base 5, and the position corresponding to the roll is on the positioning sleeve 7. There is a positioning hole, the push rod of the oil cylinder 12 passes through the positioning hole to withstand the roll, the positioning sleeve 7 is set on the right side of the support seat 5, and the left side of the support seat 5 is provided with a bearing that can limit the axial movement of the support seat 5. The fixed set 4. The present invention replaces the original roll stand, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com