Combined charging basket of trolley-type heating furnace for thermal treatment

A heating furnace, trolley-type technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as low service life, and achieve the effects of reducing production equipment costs, manufacturing costs, and thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

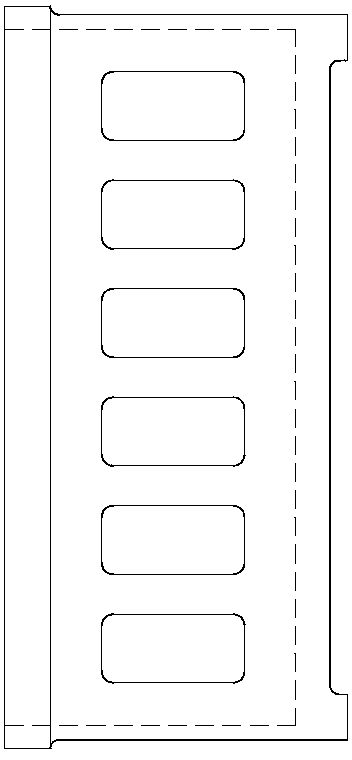

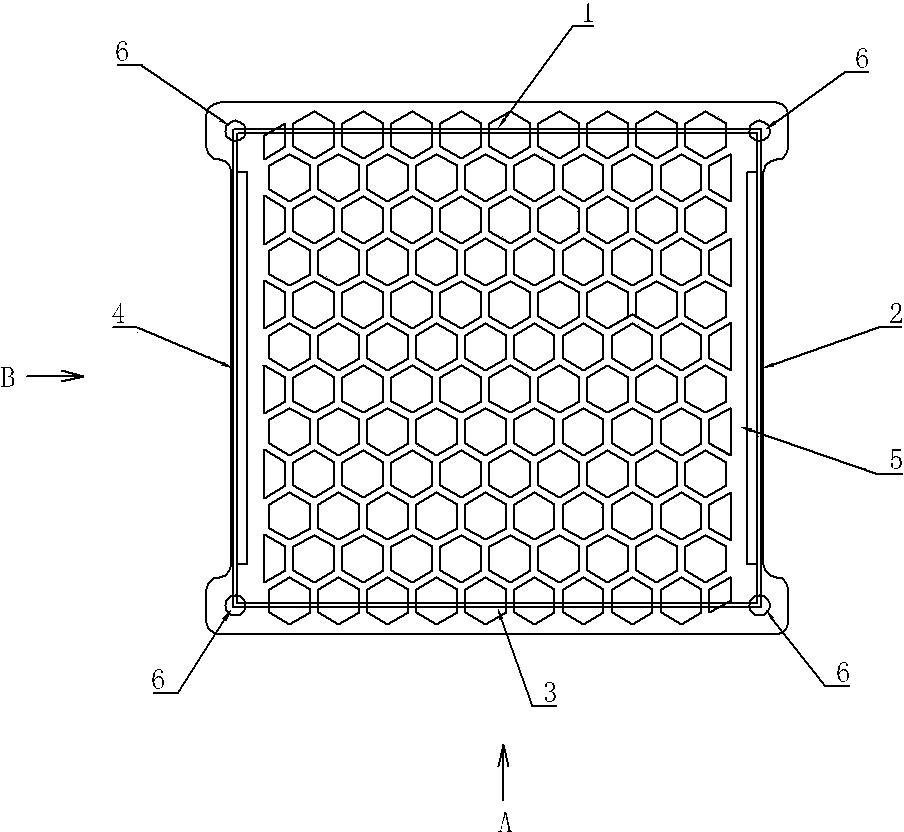

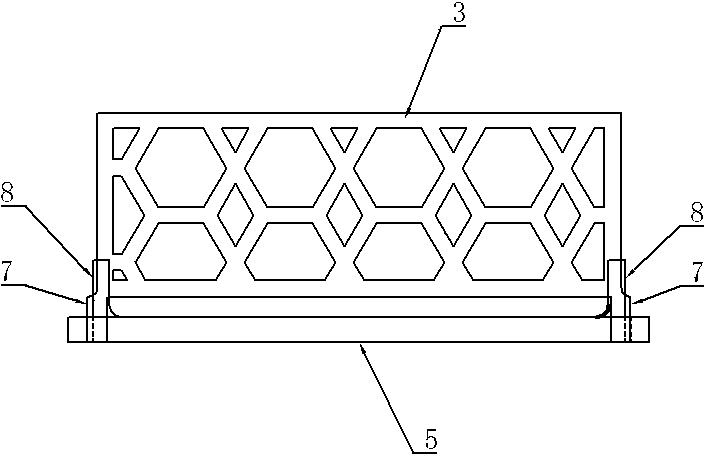

[0014] See figure 2 , image 3 , Figure 4 and Figure 5 , the present invention comprises four basket walls 1, 2, 3, 4 and a basket bottom 5, the four basket walls 1, 2, 3, 4 and the basket bottom 5 are split structures, and the four corner ends of the basket bottom 5 are respectively Mounting holes 6 are provided, and the two ends of the lower parts of the four basket walls 1, 2, 3, 4 are respectively provided with mortise feet 7. Welding platforms 8 are arranged on both lateral sides of the plane, and hanging pans for driving and lifting are welded and installed on the welding platform 8 (the hanging pans are not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com