Polysilicon ingot furnace

A technology of polysilicon ingot casting furnace and furnace body, which is applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., to achieve the effect of eliminating the danger of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, which are not drawn to scale for the convenience of illustration.

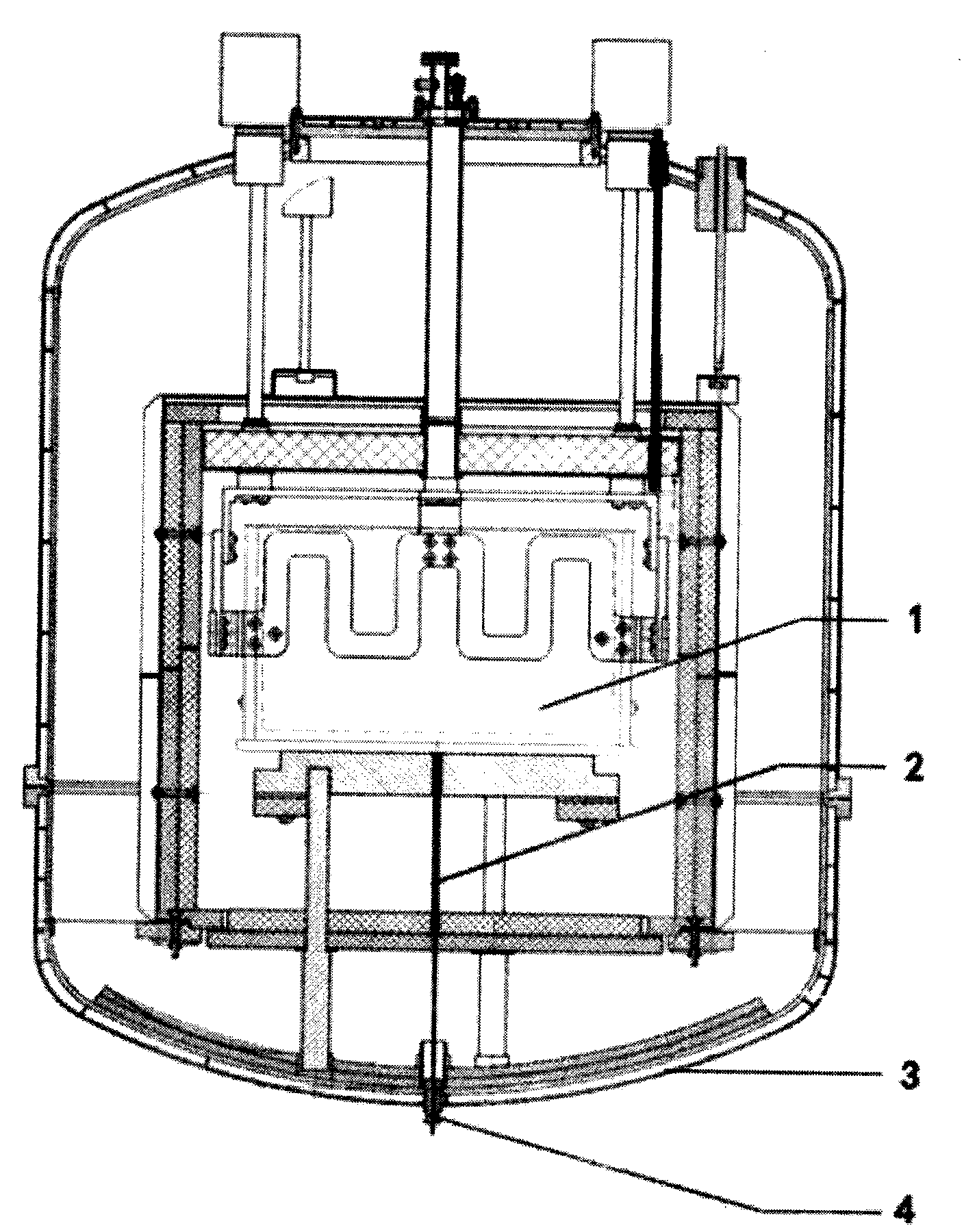

[0024] Such as figure 1 As shown, a 450-type polysilicon ingot casting furnace in the prior art is provided with a crucible 1 in the furnace body, a cooling water interlayer 3 at the bottom of the furnace body, and a steel pipe 2 for extending thermocouples into the furnace. The steel pipe 2 is connected with the bottom center 4 of the furnace body by welding. In actual production, the high-temperature silicon liquid flows out from the crucible 1, which will melt the steel wall, especially the weld at the center of the bottom 4 is easy to be melted through, thus causing the cooling water in the cooling water interlayer 3 to enter the furnace body. Under the high temperature above 1000℃ in the furnace, the water evaporates rapidly to form high-temperature water vapor, and part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com