Cut piece seal splitting and integrating clamping device

A sealing separation and clamping technology, which is applied in textiles and papermaking, fiber treatment, wadding treatment, etc., can solve the problems of affecting the quality of the sealing, the quality of the sealing is reduced, and the middle of the sealing is prone to wrinkles, etc., to achieve high quality and not easy The effect of wrinkling and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

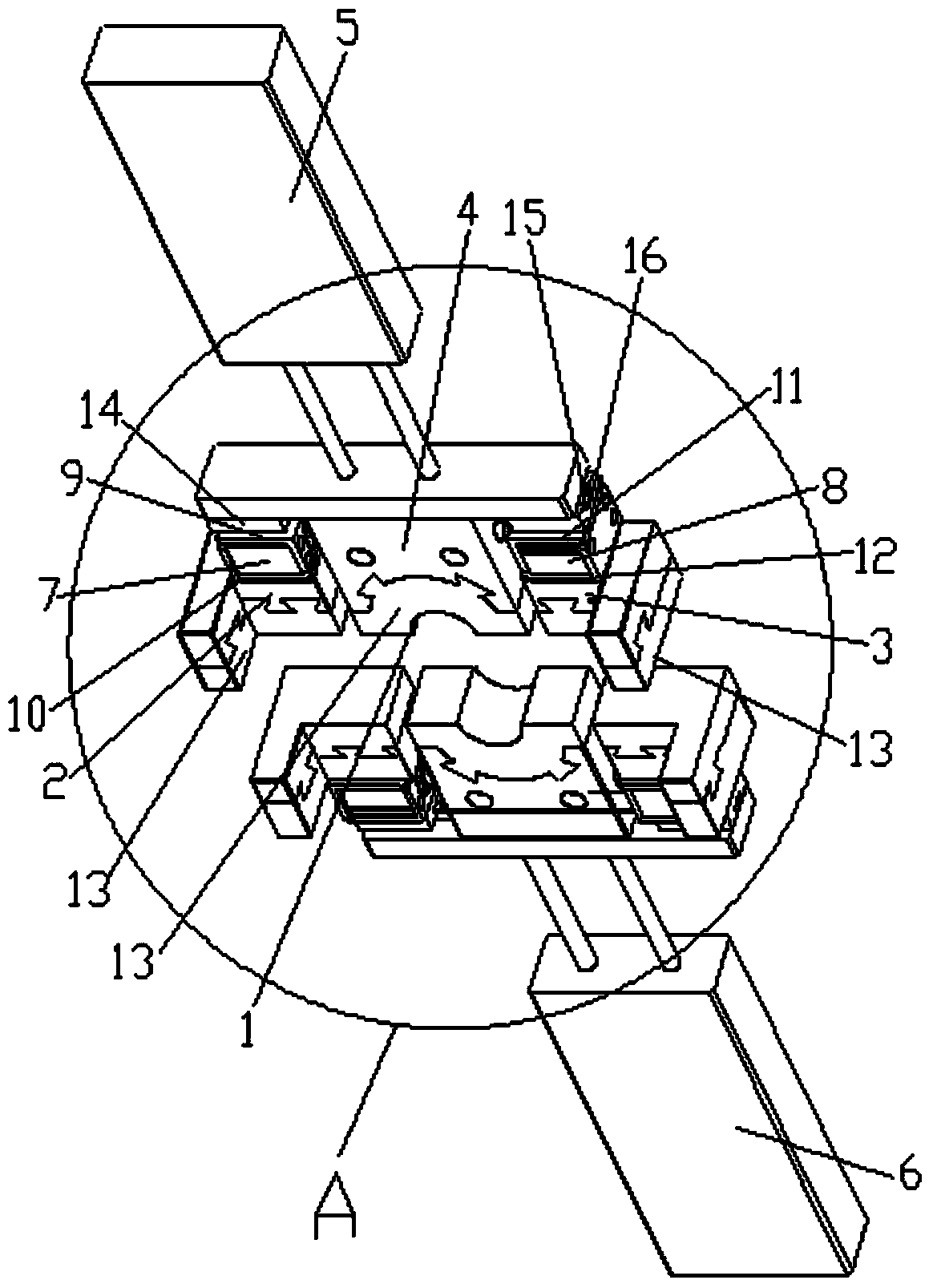

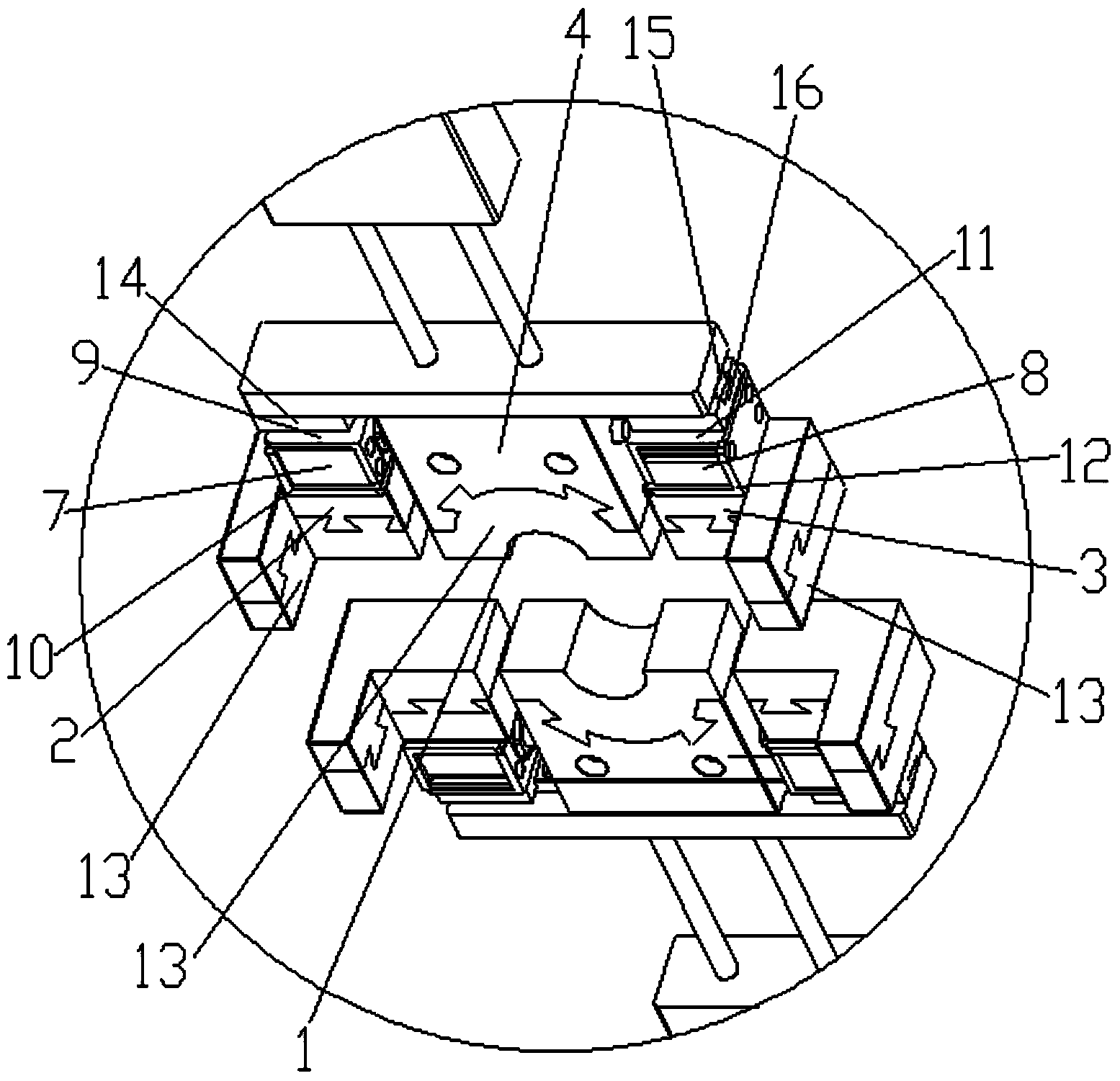

[0017] as attached Figure 1-2 The shown piece sealing separation and clamping device according to the present invention includes an upper pressing device and a lower pressing device, and a first driving device and a second driving device for respectively controlling the upper and lower pressing devices to move up and down. Two driving devices; the lower surface of the upper pressing device has a semicircular groove 1 matched with the front end of the down filling tube; the upper pressing device includes a first pressing block 2, a second pressing block 3, a clamp Tight block 4, the third driving device and the fourth driving device; the first pressing block 2 and the second pressing block which can move left and right through the third driving device and the fourth driving device are arranged below the first driving device 3. A clamping block 4 is provided between the first pressing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com