A sock labeling and bagging machine

A technology for labeling bagging machines and socks, which is applied in the field of labeling and bagging machines for socks. It can solve the problems that the front and back sides cannot be pasted at one time, it is difficult to fully automate packaging, and the packaging quality is difficult to guarantee, so as to achieve smooth sealing and high degree of automation. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

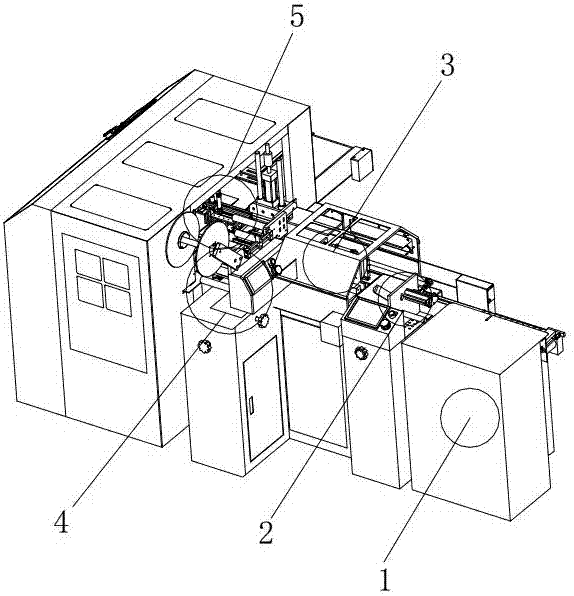

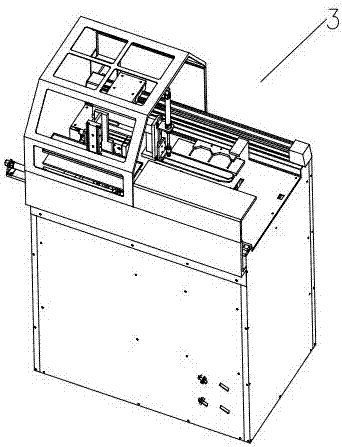

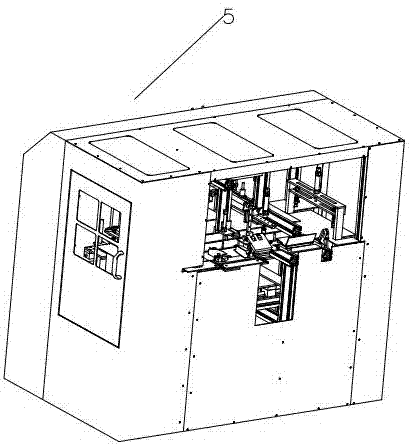

[0025] Such as Figure 1-12 As shown, a sock labeling and bagging machine includes a frame on which a sock receiving device 1, a sock labeling device 2, a paper card positioning device 3, a paper card post-labeling device 4 and a sleeve are sequentially arranged on the frame. Bag device 5, the paper card positioning device 3 is provided with a rotating sock clamping module 3-1, a sock clamping positioning module 3-2, a sock transmission module 3-3 and a sock clamping transmission module 3-4, the sock clamping positioning The module 3-2 is arranged between the rotating sock clamp module 3-1 and the sock conveying module 3-3, and the paper card post-labeling device 4 is arranged between the sock conveying module 3-3 and the sock conveying module 3-4 , the bag paging module 5-1, the bag moving module 5-2, the socks bagging module 5-3, the tearing and sealing film module 5-4 and the sealing bag opening module 5-5 are sequentially arranged in the bagging device 5, The sock bagging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com