Automatic bagger

A bagging machine and automatic technology, applied in the field of machinery, can solve the problems of low work efficiency, high labor intensity, and mismatched production lines, and achieve the effects of high work efficiency, low labor intensity, and fast bagging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

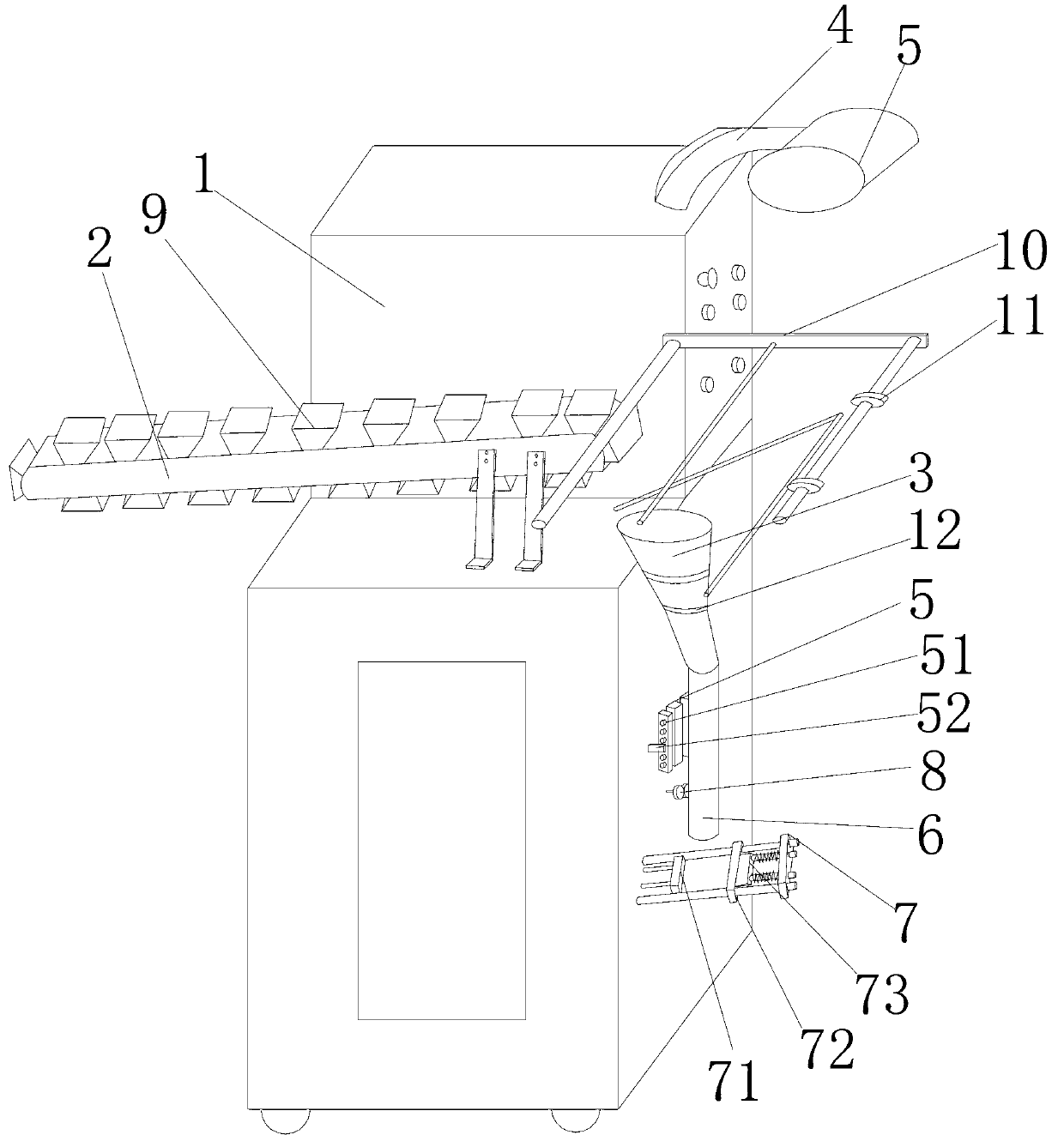

[0016] Such as figure 1 As shown, the automatic bagging machine includes a body 1, the body 1 is provided with a feeding track 2 for conveying parts, the top of the body 1 is provided with a film support 4, and the film support 4 is provided with a film Disc 5, the rear end of the feed track 2 on the body 1 is provided with a feeding funnel 3 for the film that is sheathed on the film disc 5, and the body 1 is provided with a pair of feeding funnels that are sleeved on the film disc 5 The film on the 3 is subjected to thermoplastic treatment to form a film thermoplastic device of a packaging bag, and the feeding funnel 3 is provided with a discharge port 6 for putting parts into the packaging bag. The film thermoplastic device includes a film side thermoplastic part 5 located on the side of the feeding funnel on the fuselage 1, and a film bottom thermoplastic part located on the fuselage 1 and located at the discharge port 6 of the feeding funnel 3 7. The thermoplastic part 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com