Improved wind power overturning rapid inner film sleeved method

A fast and wind-powered technology, applied to paper/cardboard containers, containers, bag making operations, etc., can solve the problems of reduced bagging efficiency, limited bagging speed, and blockage at the mouth of woven bags, achieving high flatness and mechanism Easy to make, fast bagging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

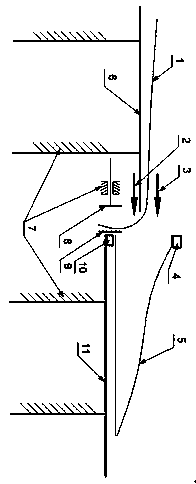

[0015] Example: such as figure 1 As shown, the inner membrane clamping device is composed of a front clamping plate 8 and a rear clamping plate 9, the bagging nozzle is composed of an upper bagging nozzle 3 and a lower bagging nozzle 2, and the woven bag opening device is composed of an upper opening Pocket plate 4 and following pocket plate 10 form. The intima platform 6 and the woven bag platform 11 are fixed on the frame 7 . The intima 1 cut off by the previous process is placed on the intima platform 6, and is moved forward by the front clamping plate 8 in the intima clamping device until it touches the front clamping plate 9, so that the end of the endometrium 1 has been cut. The lower part is clamped under the platform 6 of the intima. At the same time, the woven bag 5 cut off has been delivered to the woven bag platform 11, and the upper bag-opening plate 4 descends to contact and absorb the upper layer woven bag and then rises, and the lower bag-opening plate 10 abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com