Automatic bottom-sealing type corrugated case

A corrugated box and bottom sealing technology, which is applied in the field of automatic bottom-locking corrugated boxes, can solve the problems of cover plate and bottom plate bending, edge warping, impact of stacking and transportation, and decrease of compressive strength, so as to improve the compressive strength, Simple structure and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

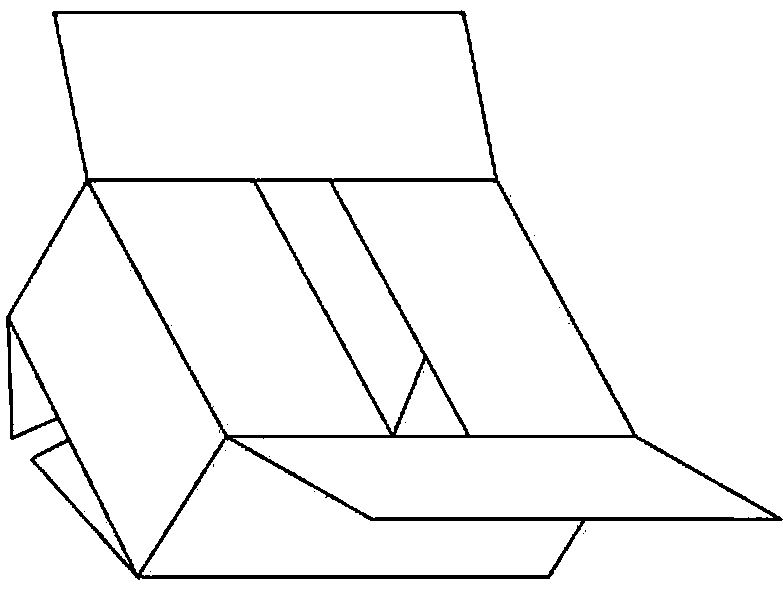

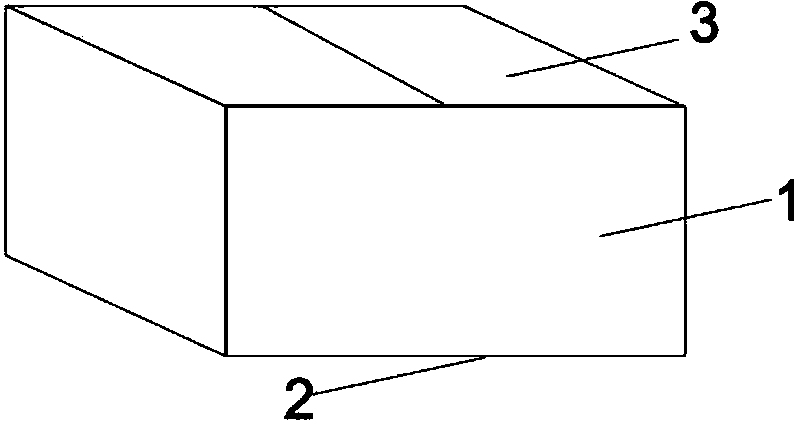

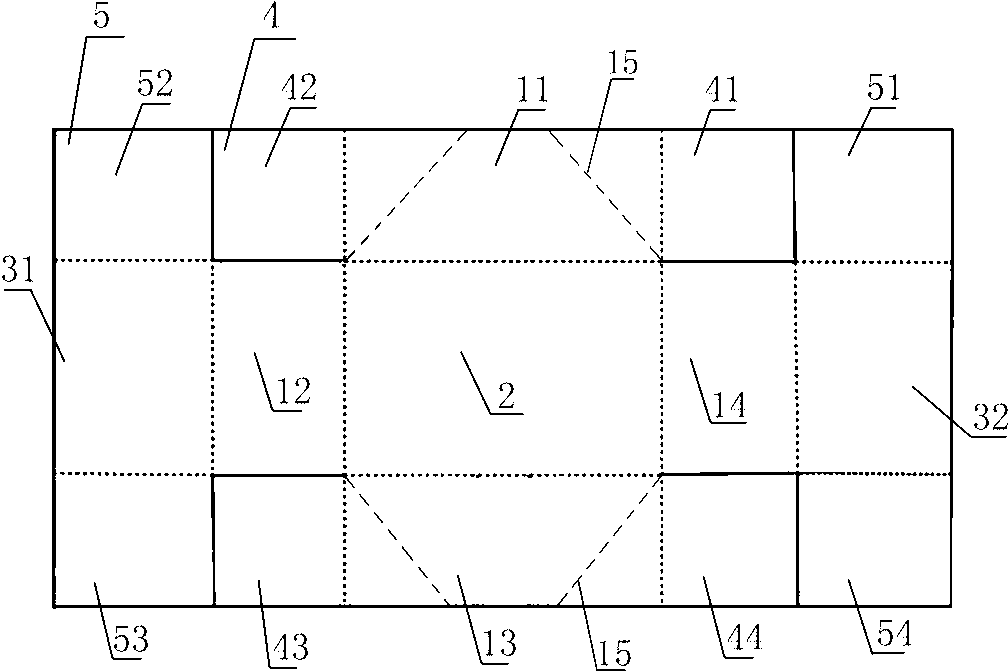

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: figure 2 , 3 , 4, it is made of a piece of cardboard by pressing the creases on it, and mainly includes a square box made of side panels 1, bottom panels 2 and cover panels 3; the cover panel 3 is made of the first A cover plate 31 and a second cover plate 32 are formed; the side plate 1 is composed of a first side plate 11 and a third side plate 13 fixedly connected to a group of opposite sides of the bottom plate 2, fixedly connected to the bottom plate The second side plate 12 and the fourth side plate 14 on the other set of opposite sides of 2 are formed; the first side plate 11 and the third side plate 13 are provided with two mutually symmetrical sides and the bottom edge of the side plate. An indentation line 15 at an angle of 45 degrees, the indentation line 15 is an inner fold line, by folding the indentation line, the side panel 1 is folded inward and attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com