Fast connector for tracks

A technology of rail and female joints, which is applied in the field of connection devices for mine suspension rails, can solve problems such as unsafety, safety hazards, and deformation of rail joints, and achieves the elimination of crane operation accidents, low labor intensity, and smooth operation. the effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

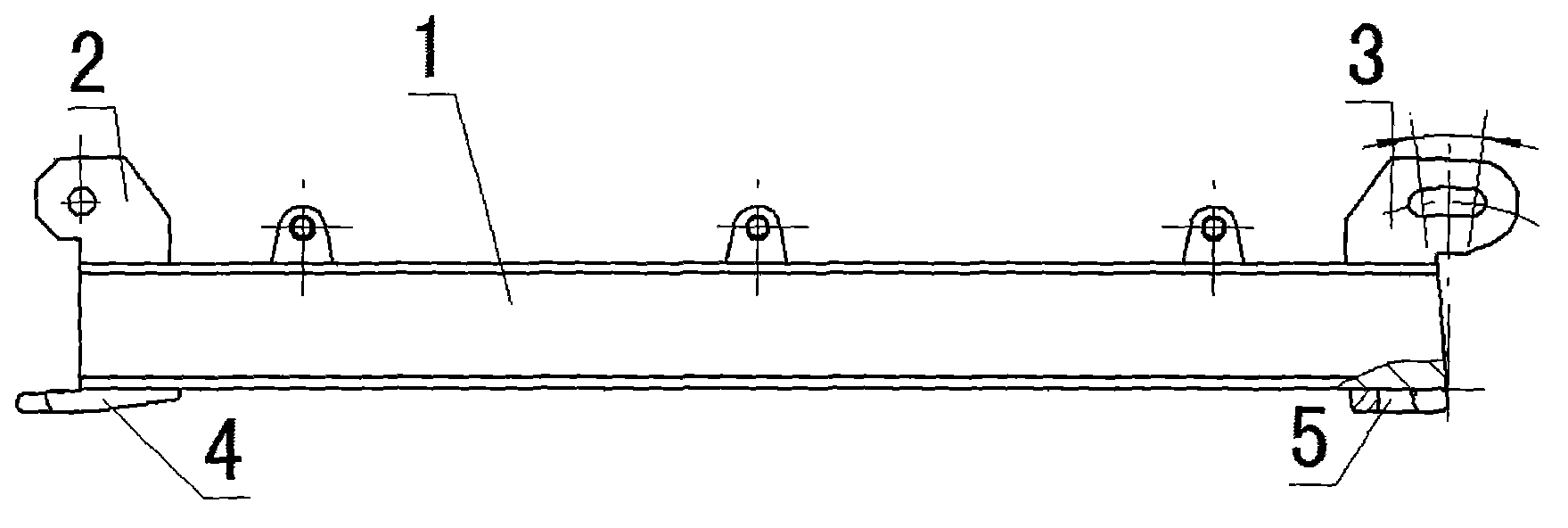

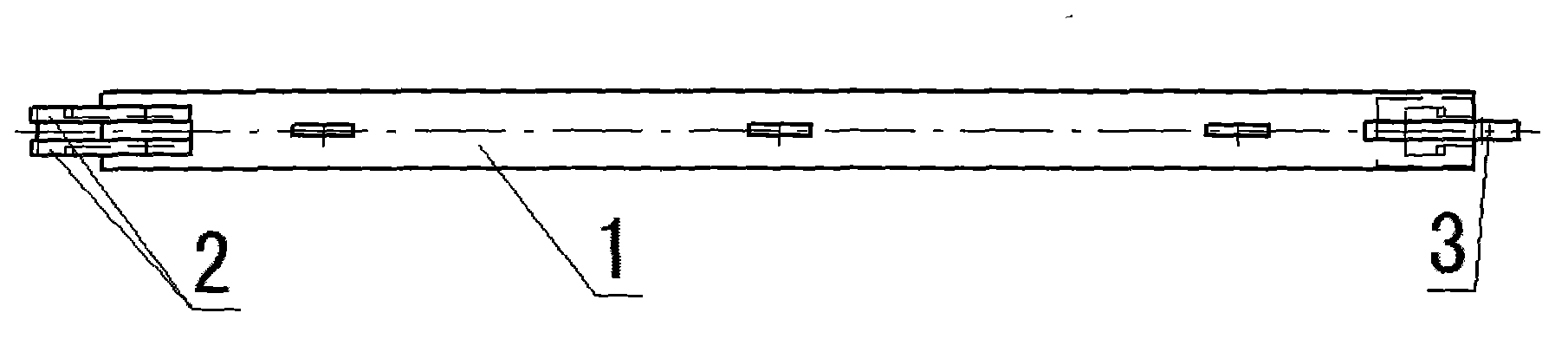

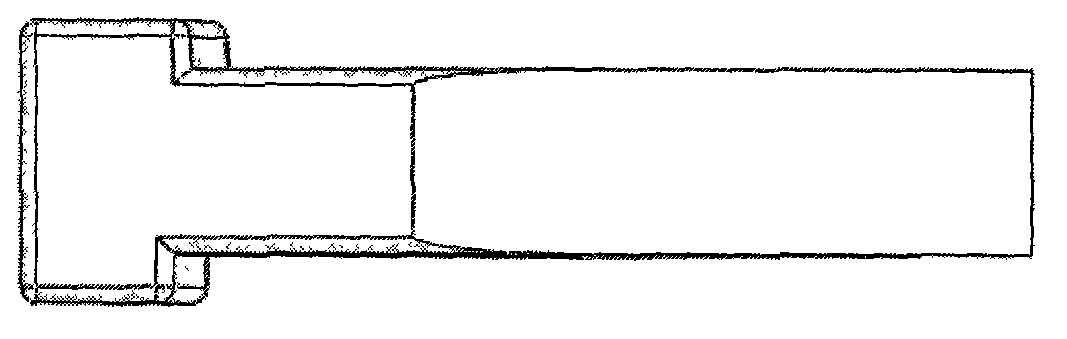

[0010] One end of the track 1 is processed into an up and down inclined end face, the inclination is one-half of the included angle of the arc, and a connecting ear 3 is welded above the inclined end face. There is an arc-shaped hole on the connecting ear 3, and the center of the arc is located On the lower edge, the included angle of the arc is 5 to 10 degrees. There is a female joint 5 welded on the lower edge of the inclined end surface, and there is a shovel-shaped groove on the female joint 5; the other end of the track 1 is a vertical end surface, and two vertical end surfaces are welded above Parallel connecting ears 2, there are concentric holes on the connecting ears 2, the distance between the two connecting ears 2 is equal to or greater than the thickness of the connecting ears 3, a male joint 4 is welded on the lower edge of the vertical end face, the male joint 4 is in the shape of a shovel, the same as the female joint The grooves on the 5 have the same shape and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com