Method for producing methane by converting carbon dioxide through methanobacterium thermaggregans in activated reservoir

A technology for producing methanogens and carbon dioxide, which is applied in the field of development and utilization of oil reservoir microorganisms, can solve the problems of low concentration and low metabolic activity of oil reservoir microorganisms, and achieve the effect of increasing the rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

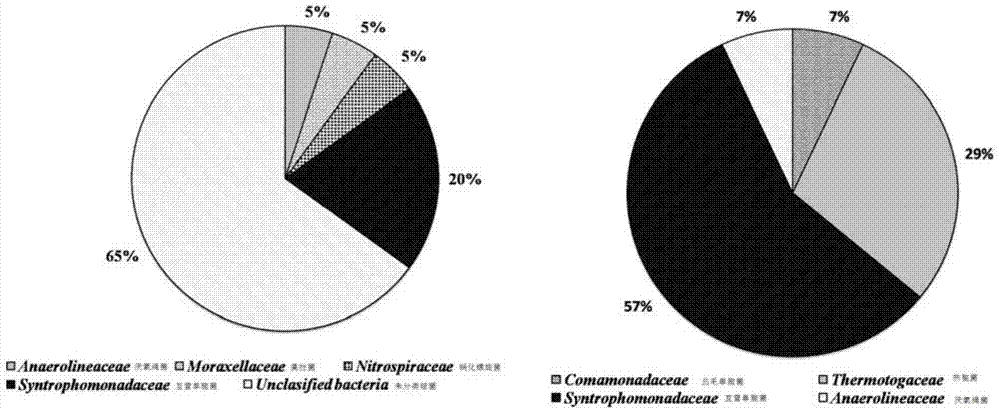

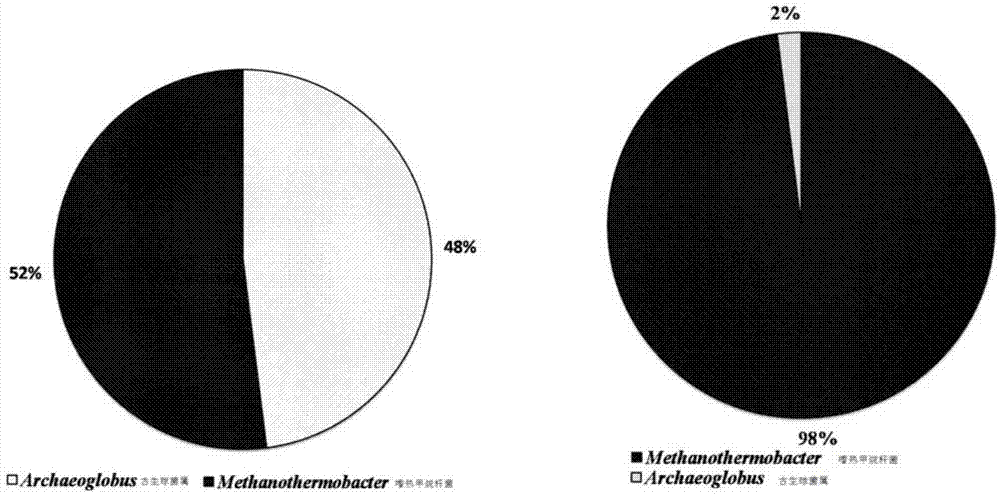

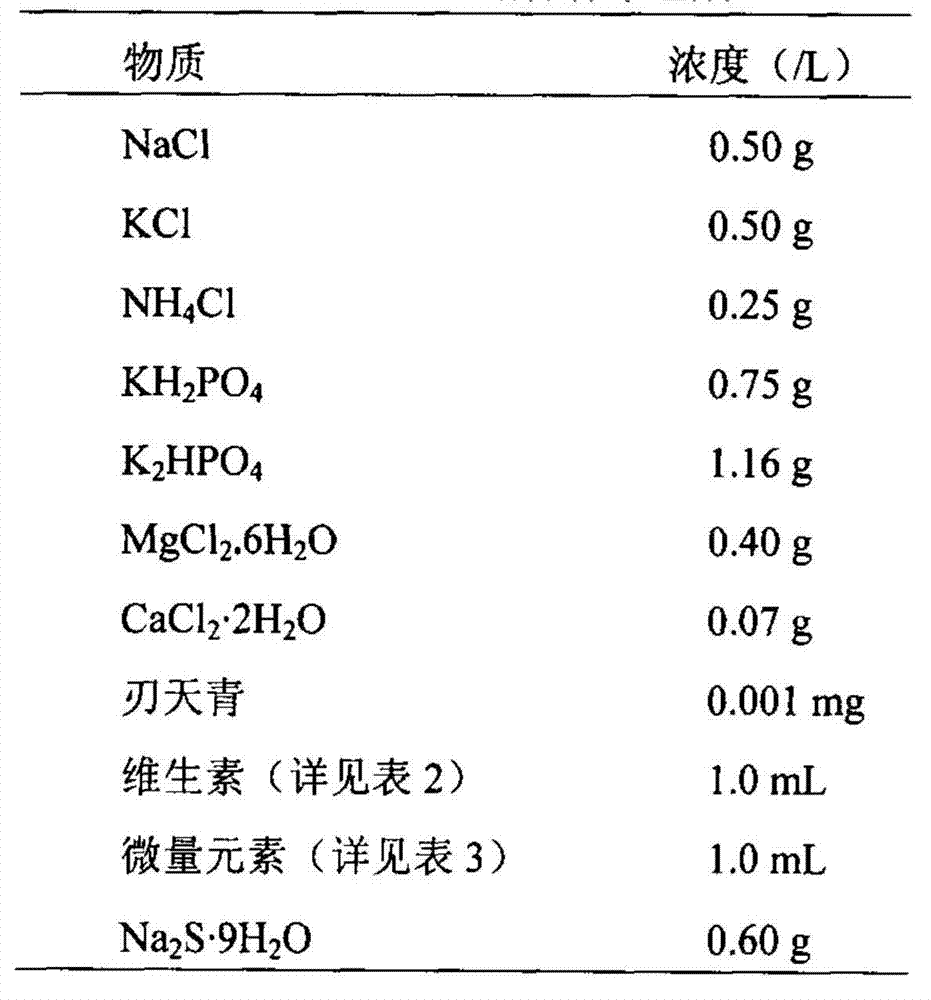

Embodiment 1

[0019] The output fluid of a certain block in Daqing Oilfield was analyzed to contain Syntrophomonadaceae, Thermotogaceae and Methanothermobacter, and two culture systems were prepared with the output fluid (see the table for system composition 1~3), cultured at 55°C for 180 days, no CH was detected in the system 4 , indicating that the activity of methanogens in the system was very low. Then one of the systems remained unchanged, and 0.41g (5mM) sodium acetate was added to the other system, and cultured for 12 days, CH was detected in both systems. 4 , CH in the two systems after 120 days of culture 4 The contents were 18.3mmol / L (with sodium acetate added) and 2.7mmol / L (without sodium acetate added). For analysis of the 2 phylogenetic communities, see figure 1 and figure 2 . Depend on figure 1 It can be seen that the abundance of Syntrophomonadaceae increased from 20% (without adding sodium acetate system) to 57% (with adding sodium acetate system). Depend on figu...

Embodiment 2

[0021] Analysis of the production fluid of a block in Huabei Oilfield contains 9.5% Syntrophomonadaceae and 18.3% Methanobacterium and 10.8% Methanolinea, and two culture systems were prepared with the production fluid (See Tables 1-3 for the system composition), cultured at 38°C for 100 days, no CH was detected in the two systems 4 , indicating that the activity of methanogens in the system was very low. Then keep one system unchanged, add 0.56g (6.8mM) sodium acetate to the other system, and detect CH in the two systems after continuing to cultivate for 33 days. 4 , CH in the two systems after 75 days of culture 4 The contents were 4.7mmol / L (without adding sodium acetate) and 22.4mmol / L (with adding sodium acetate). The abundance of Syntrophomonadaceae in the system increased from 20% (without adding sodium acetate system) to 57% (with adding sodium acetate system). Methanobacterium and Methanolinea increased from 18.3% and 10.8% in the system without sodium acetate to 3...

Embodiment 3

[0023]Analysis of a block in Xinjiang Oilfield contained 15.7% of Syntrophomonadaceae, 9.6% of Thermotogaceae, 23.2% of Methanobacterium, and 13.7% of Methanocystis (Methanoculleus), two culture systems were prepared with this output liquid (see Table 1-3 for system composition), cultured at 21°C for 64 days, no CH was detected in the two systems 4 , indicating that the activity of methanogens in the system was very low. Then keep one system unchanged, add 0.98g (10mM) potassium acetate to the other system, and continue to cultivate for 23 days, CH 4 , CH in the two systems after 143 days of culture 4 The contents were 3.2mmol / L (without potassium acetate system) and 37.2mmol / L (with potassium acetate system). The abundance of Syntrophomonas (Syntrophomonadaceae) in the system increased from 15.7% (without adding potassium acetate system) to 37.6% (with addition of potassium acetate system), and the abundance of Thermotogae (Thermotogaceae) changed from 9.6% (without adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com