Non-return structure of manual pump

A manual pump and pump body technology, applied in the field of manual pumps, can solve problems such as wear at the inlet, affect the power supply of the pump body, and steel ball wear, and achieve high hardness, reduce impact wear, and reduce the chance of collision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

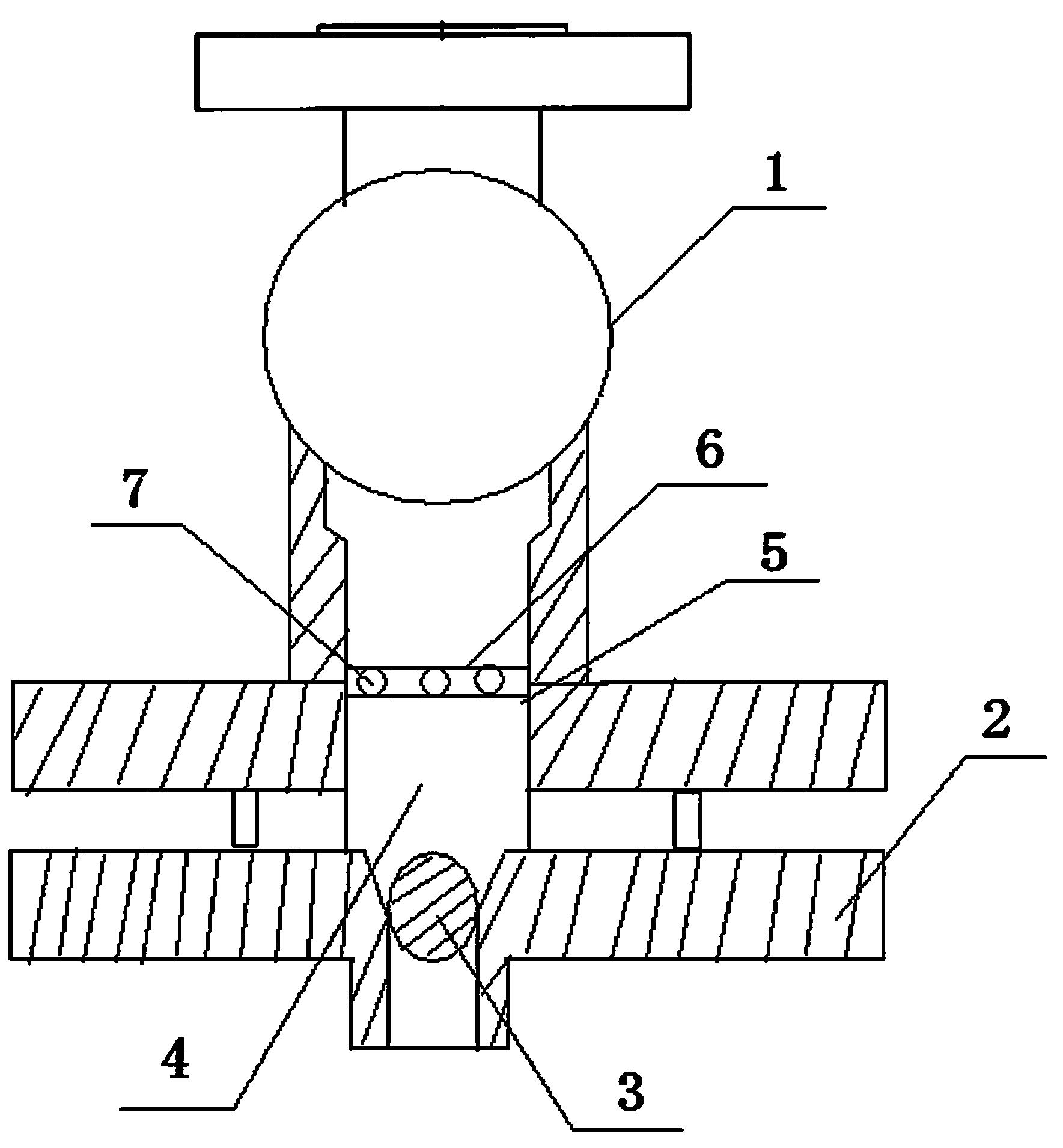

[0012] like figure 1 As shown, a check structure of a manual pump includes a pump body 1 and a flange 2 placed at the bottom of the pump body 1. A steel ball 3 and a cavity 4 are arranged inside the flange 2. The cavity 4 The inlet 5 of the top pump body is provided with a screen 6 with several mesh holes 7 , and the diameter of each mesh hole 7 is 2mm smaller than the diameter of the steel ball 3 .

[0013] The above-mentioned screen 6 can effectively prevent the steel ball 3 from entering the pump body 1. Because the mesh 6 has a large number of mesh holes 7 and is 2mm smaller in diameter than the steel ball 3, it does not affect the power supply of the pump body 1 on the one hand. On the other hand, the chance of the steel ball 3 colliding with each mesh hole 7 is reduced, the steel ball 3 and the mesh hole 7 are not eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com