Hydraulic control method and device for top bolt oil cylinder of internal mixer

A control device and mixer technology, which is applied to fluid pressure actuating devices, mechanical equipment, servo motor components, etc., can solve the problems of difficult implementation, complex structure, large volume, etc., and achieve stable control, high control precision, On-site debugging of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

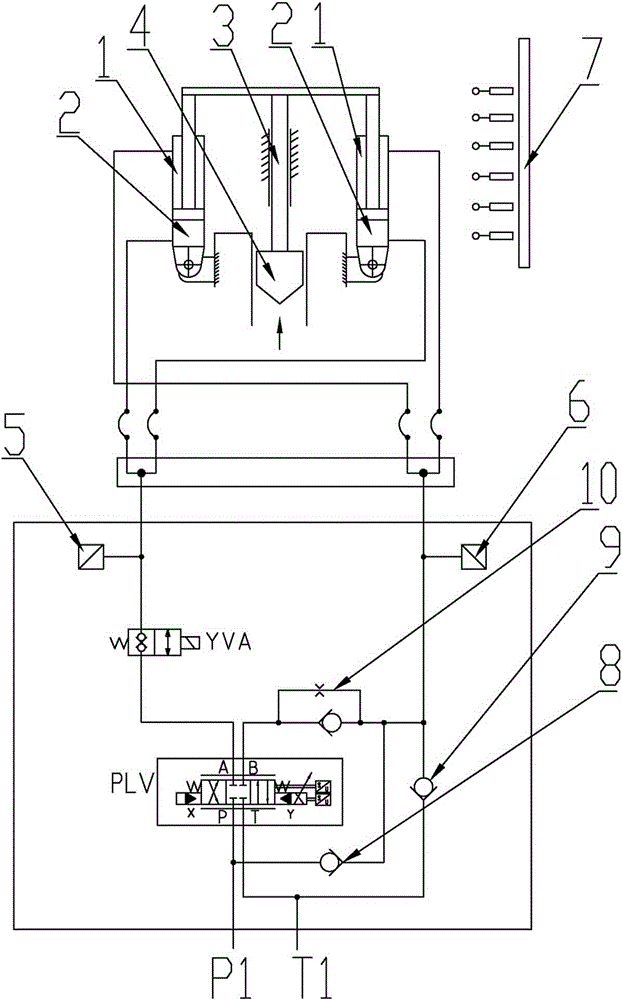

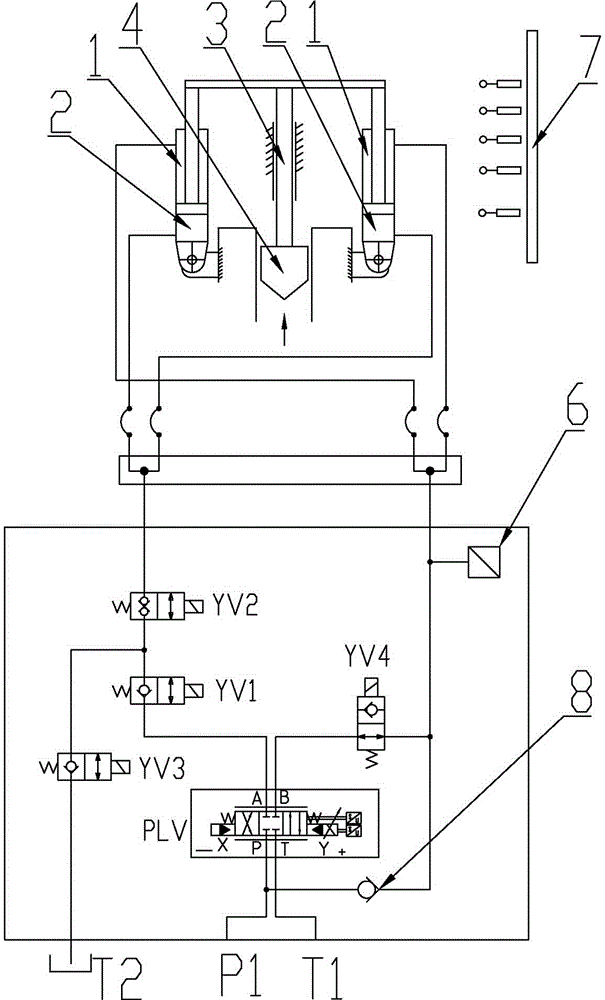

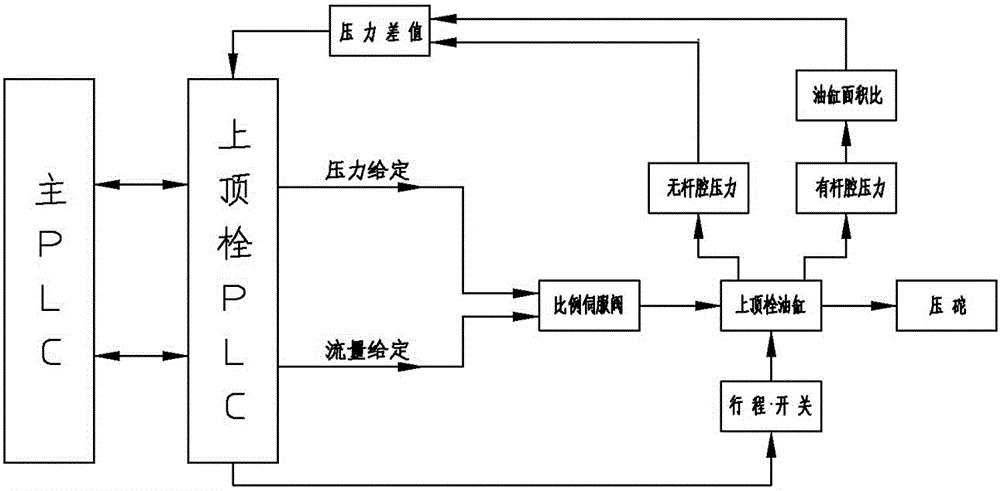

[0013] Depend on figure 1 , figure 2 It can be seen that in the hydraulic control of the top bolt of the existing internal mixer, the working conditions of the lifting weight, weight falling, pressurization, and floating weight all input current signals to the given plate through the upper jacking bolt PLC and switch between open and closed loops. signal to achieve. In the rising and falling control of the weight 4, the open-loop flow control is adopted, that is, the PLC inputs a given signal to the flow given plate, and the hydraulic oil passes through the oil pipe through the oil inlet P1, the proportional servo valve PLV, and the electromagnetic cartridge valve. YVA or proportional servo valve PLV, check valve 10 with damping port feeds oil into rodless chamber 2 or rod chamber 1 of the upward jacking cylinder to realize the rise or fall of upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com