Multi-cylinder continuous propulsion system

A propulsion system and rear propulsion technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of long retraction length, inability to process, difficult installation, etc., to achieve the effect of no pressure shock, stable operation, and realization of thrust over-limit protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

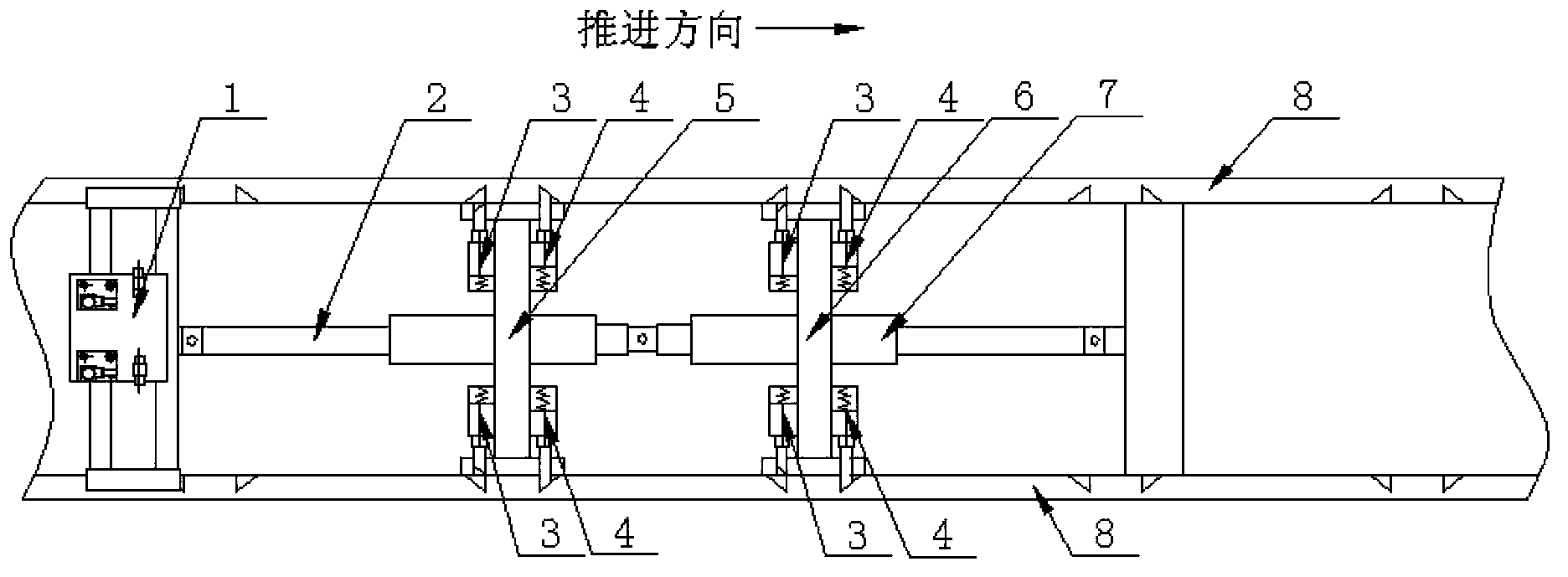

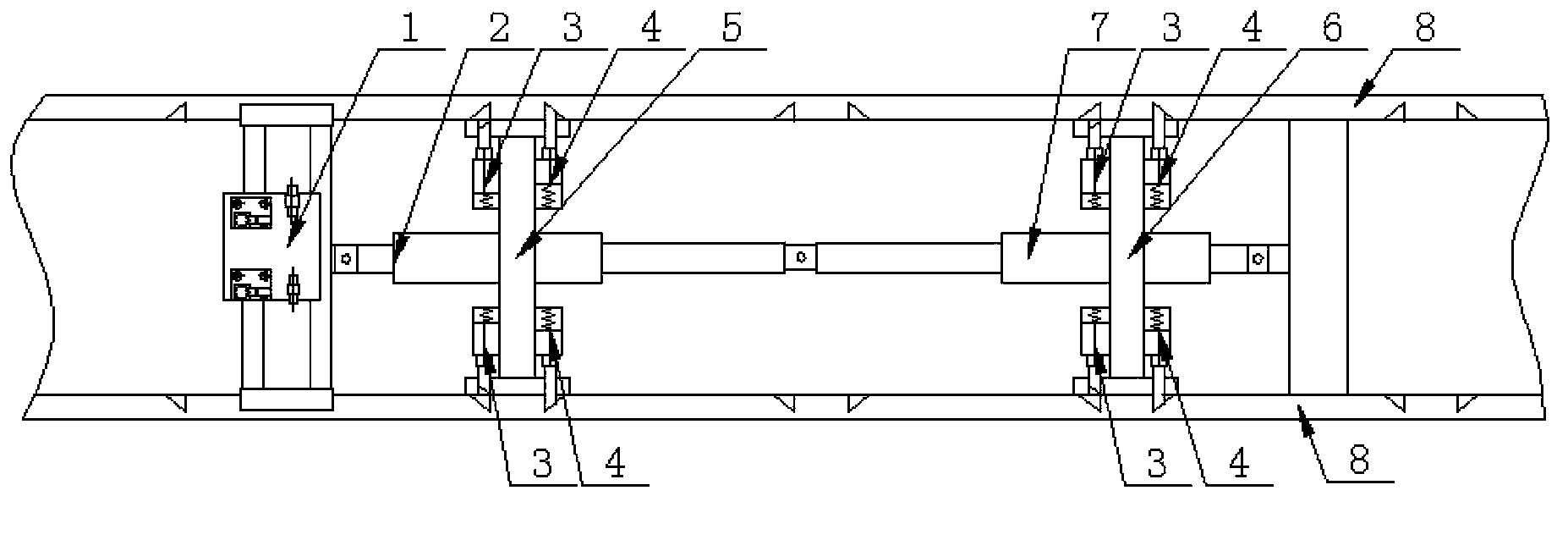

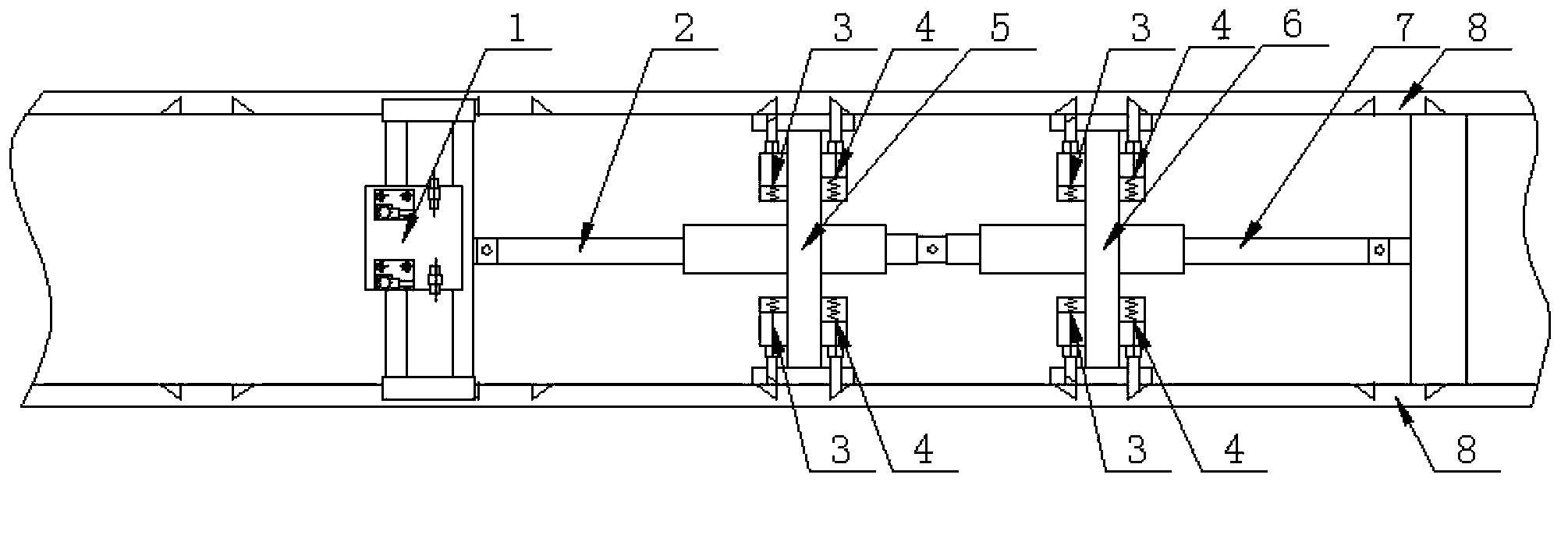

[0016] Such as figure 1 As shown, the multi-cylinder continuous propulsion system includes a control valve group 1, a rear propulsion cylinder 2, a forward propulsion cylinder 7, four forward insertion cylinders 4, four backward insertion cylinders 3, a front carriage 6, a rear carriage 5 and Rail 8. A stroke switch is installed on the forward plugging cylinder 4 and the backward plugging cylinder 3, and the stroke switch is triggered when the piston rod of the forward plugging cylinder 4 or the backward plugging cylinder 3 stretches out. The cylinder barrel of the forward plug-in cylinder 4 and the cylinder barrel of the forward push cylinder 7 are all fixed on the front carriage 6 with bolts respectively; On the rear carriage 5. One end of the rear propelling cylinder 2 is fixedly connected with the control valve group 1 by screws. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com