a solenoid valve

A technology of solenoid valve and valve sleeve, applied in the field of solenoid valve, can solve the problems of insufficient electromagnetic force, not very safe, pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

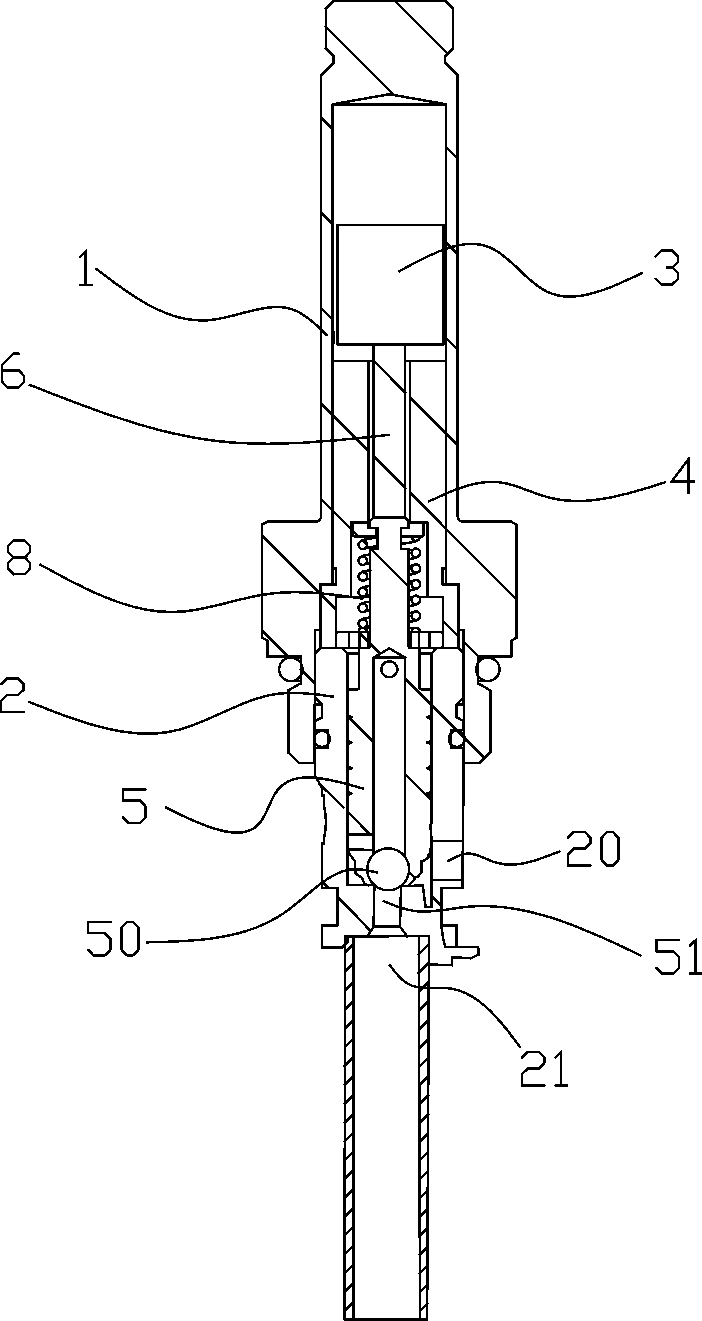

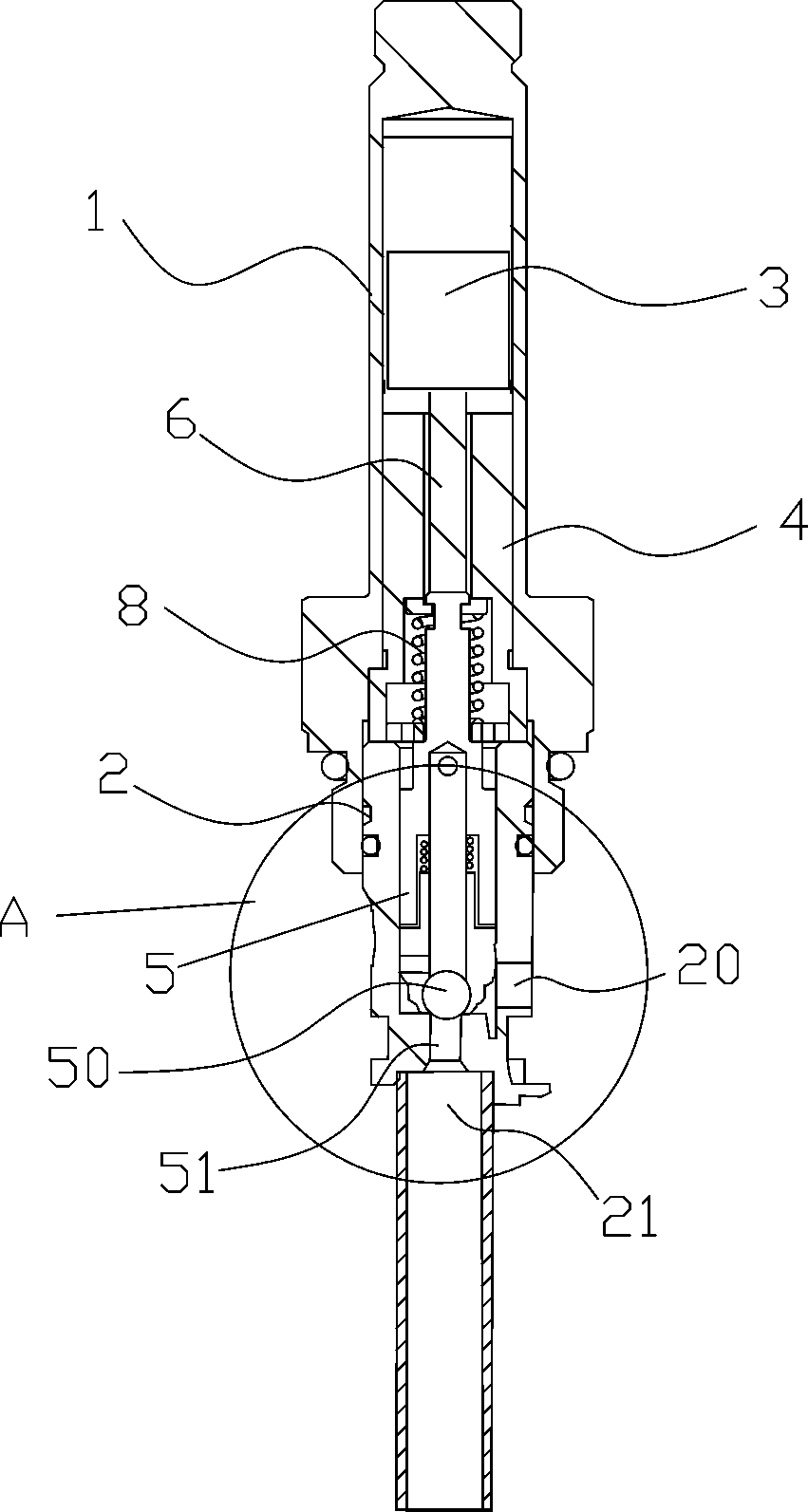

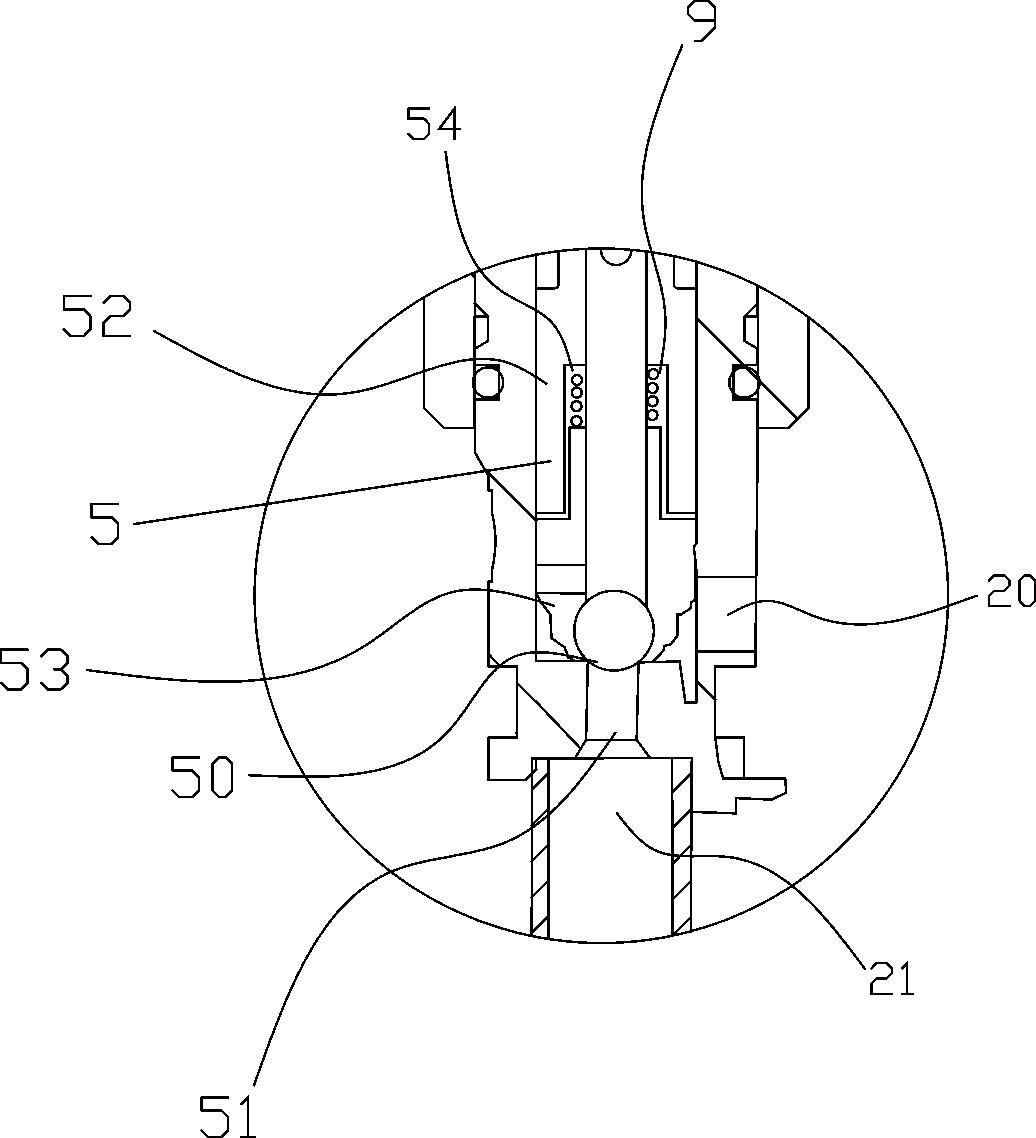

[0011] The present invention will be further described in detail below. In this embodiment, preferably, both the elastic member 9 and the reset member 8 are springs. see Figure 1 to Figure 3 , a solenoid valve, comprising a magnetic sleeve 1, a moving iron 3 is slidably arranged in the hollow cavity of the magnetic sleeve 1, and a fixed iron 4 is slidably arranged in the cavity of the magnetic sleeve 1 at intervals of the moving iron 3; the valve Sleeve 2, the valve sleeve 2 is fixed on the front end of the magnetic sleeve 1, and the end and side wall of the valve sleeve 2 are respectively provided with an oil inlet 20 and an oil outlet connected to the inner cavity of the valve sleeve 21. Coil (not shown in the drawings), the coil is wrapped on the outside of the magnetic sleeve 1, and provides a magnetic field that moves the moving iron 3 to the fixed iron 4 when the coil is energized; the valve core 5 , the spool 5 is slidably arranged in the inner cavity of the valve sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com